Method for treating sewage by DSD acid reduction acid bleeding

A treatment method and technology for reducing acid, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Complete, the production unit is unbearable and other problems, to achieve the effect of improving the separation performance of mud and water, no secondary pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

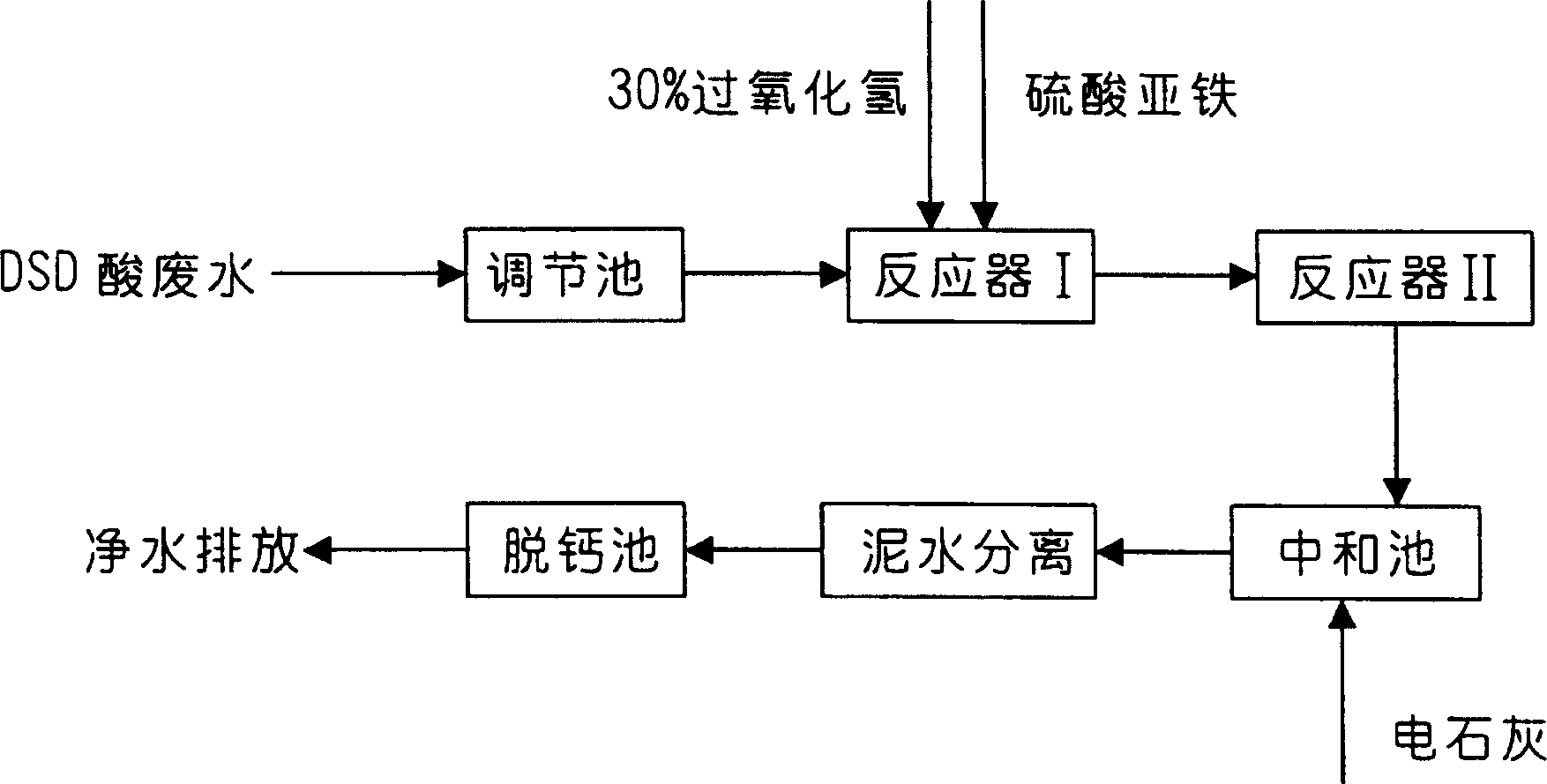

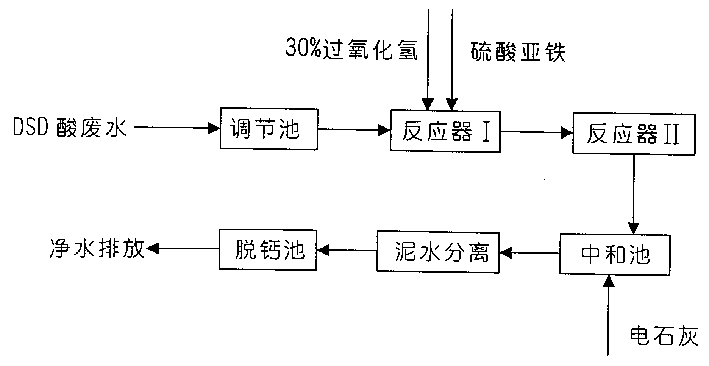

[0024] Reductive acid analysis wastewater is discharged from the workshop, first enters the adjustment tank and mixes thoroughly, controls pH 3.5, temperature 40°C, then pumps it into reactor I, adds hydrogen peroxide 1.5Kg / ton wastewater into reactor I, ferrous sulfate 0.2 Kg / ton of wastewater, the reaction time is more than 0.5 hours, the longer the time, the better the effect. After the reaction, the wastewater flows to the reactor II equipped with iron-carbon filler. The iron-carbon filler is to mix iron filings and coke with a particle size of 2-10mm evenly After loading into the reactor, the filling ratio of coke and iron filings can be 1-5:1-99, the better ratio is 1-5:95-99, the micro-electrolysis reaction time is more than 0.5 hours, the longer the time, the better the effect , and then poured into the neutralization tank and neutralized to PH8 with milk of lime. After separation of mud and water by sedimentation method, the separated sludge can be used as raw material...

Embodiment 2

[0026] The steps such as its oxidation reaction, neutralization reaction, mud-water separation and decalcification are all the same as in Example 1, but the difference lies in the electrolysis reaction, which is to place an iron plate electrode in the reactor II, pass 12V direct current, and pass the oxidized waste water to into the reactor II to carry out the electrolysis reaction for more than 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com