Method for preparing single-phase copmact silicon titaium carbid block body material by using A1 as adjuvant through hot-pressing reaction in situ

A technology of silicon carbide titanium and bulk materials, which is applied in the field of preparation of ceramic materials, and can solve problems such as unsuitability for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

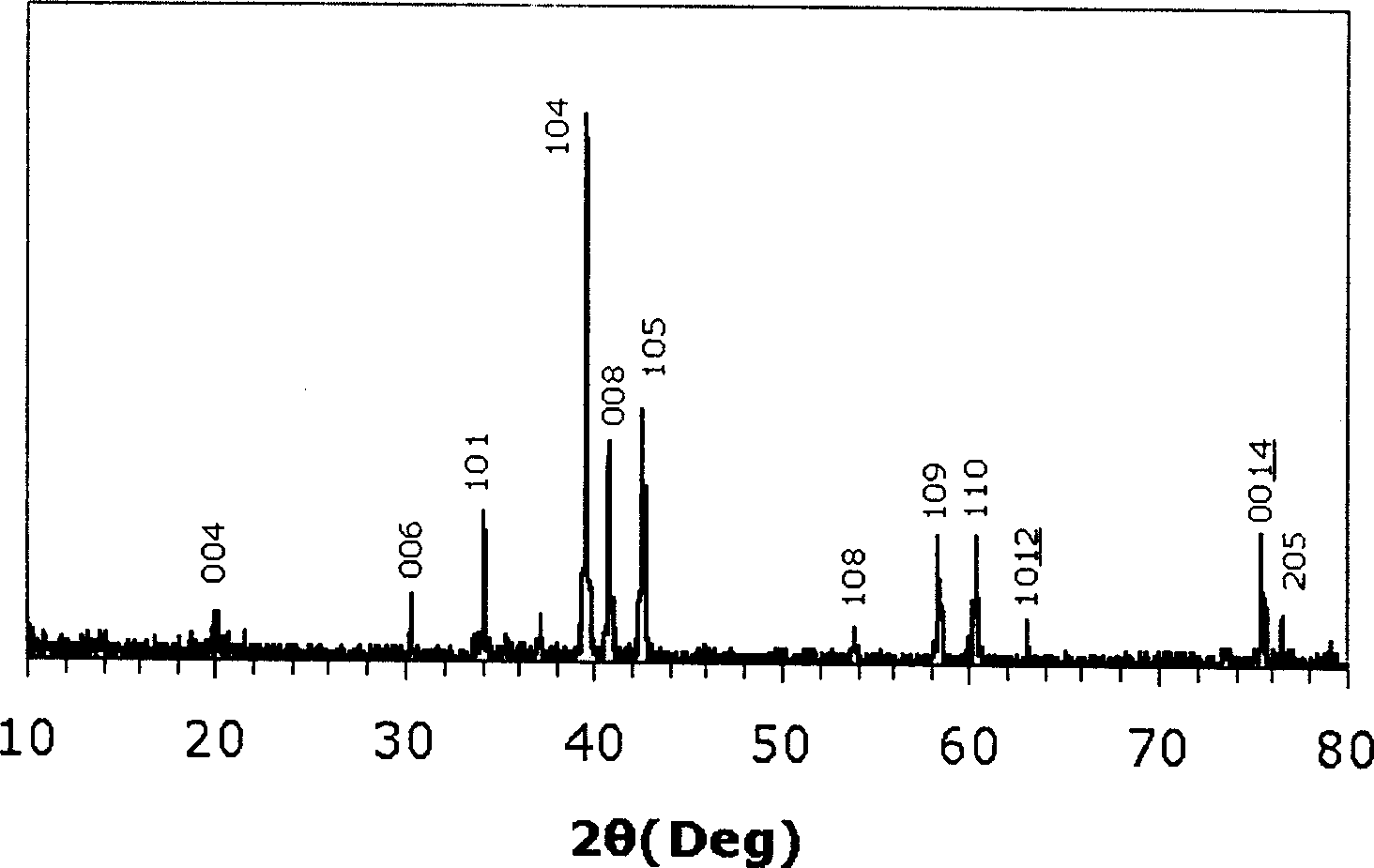

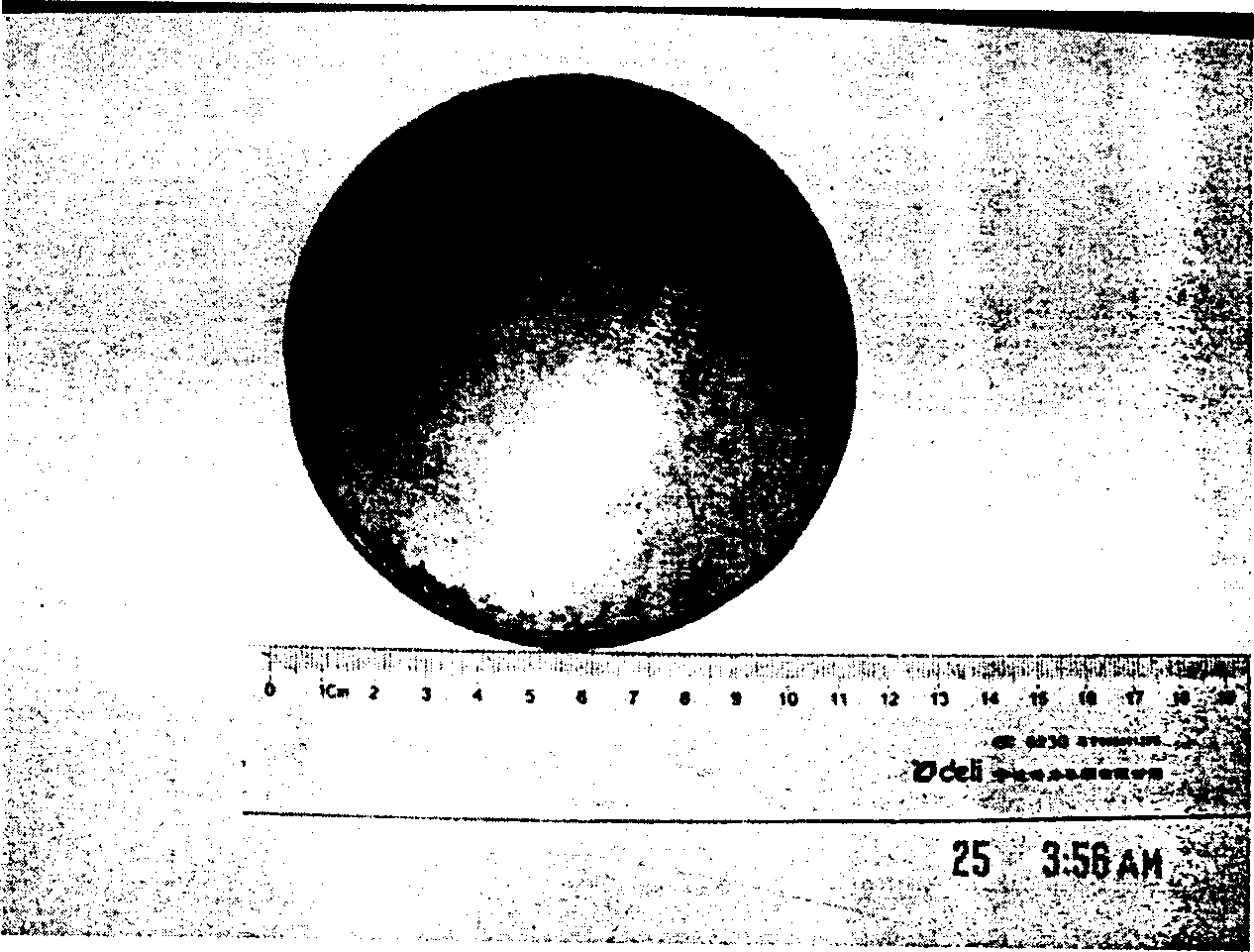

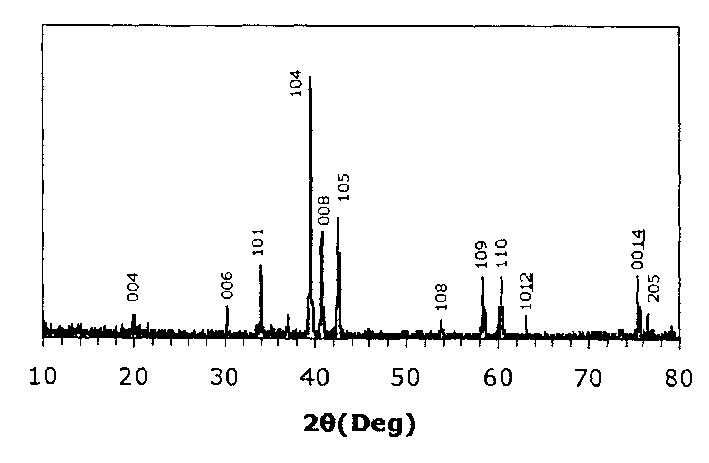

Embodiment 1

[0012] 150 grams of mixed powder with a molar ratio of TiC:Ti:Si:Al=2:1:0.95:0.25 was put into a graphite mold and sintered in an Ar protective atmosphere. The heating rate is 50°C / min, the sintering temperature is 1300°C, the pressure is 30MPa, and the heat preservation is 2 hours. The density of the bulk material is 99%, Ti 3 SiC 2 The content is 98.2wt.%. Compressive strength ≥800MPa, three-point bending strength σ b ≥420MPa, K IC ≥5MPa·m 1 / 2 .

Embodiment 2

[0014] 250 grams of mixed powder with a molar ratio of TiC:Ti:Si:Al=2:1:1.05:0.15 was put into a graphite mold and sintered in an Ar protective atmosphere. The heating rate is 50°C / min, the sintering temperature is 1400°C, the pressure is 60MPa, and the heat preservation is 6 hours. The density of the bulk material is 99.8%, Ti 3 SiC 2 The content is 99.5wt.%. Compressive strength ≥800MPa, three-point bending strength σ b ≥500MPa, K IC ≥5MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com