Method for preparing single-phase compact titanium aluminium carbon block body material by using si as adjurant through hot pressing process

A bulk material, titanium aluminum carbon technology, applied in the field of preparation of new ceramic titanium aluminum carbon materials, can solve the problems of difficult preparation, limited research and application, etc., and achieve the effect of simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

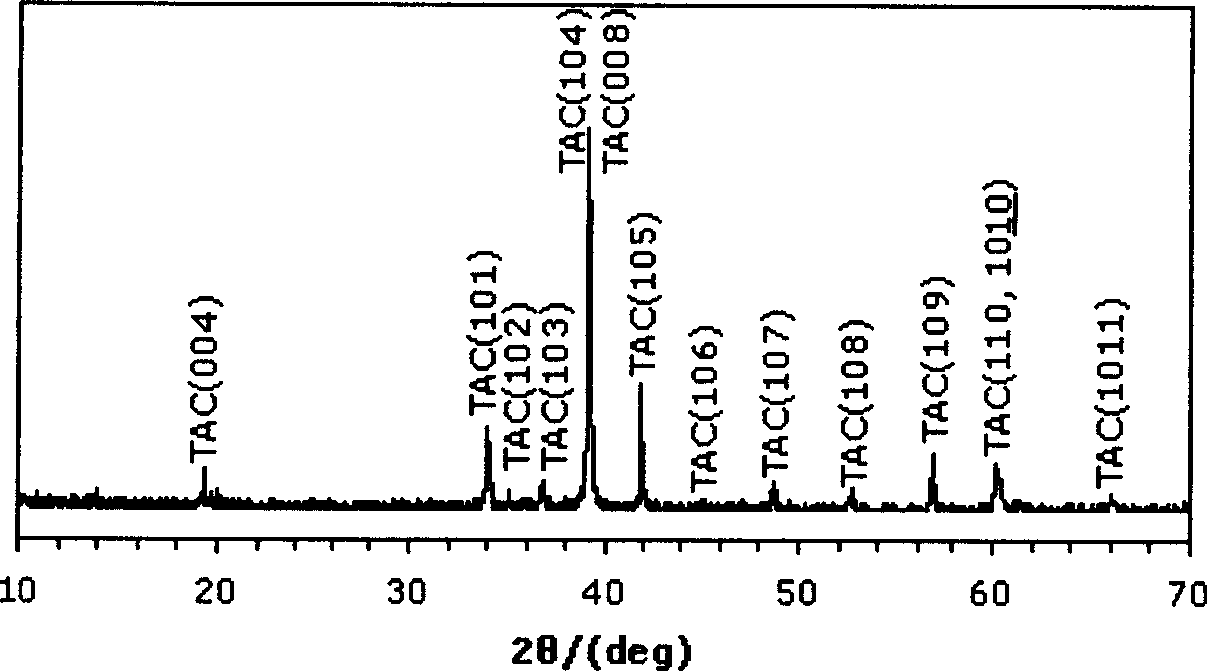

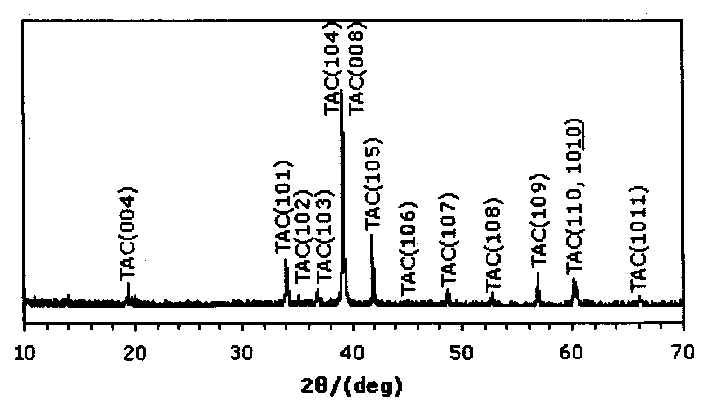

[0011] 150 grams of mixed powder with a molar ratio of TiC:Ti:Al:Si=2:1:0.95:0.25 was put into a graphite mold and sintered in a hot-press furnace with an Ar gas protective atmosphere. The heating rate is 50°C / min, the sintering temperature is 1300°C, the pressure is 30MPa, and the temperature is kept for 2 hours. The density of the bulk material is 99%, Ti 3 AlC 2 The content is 98.2wt%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥750MPa, and the three-point bending strength σ b ≥350MPa, K IC ≥5MPa·m 1 / 2 .

Embodiment 2

[0013] Put 250 grams of mixed powder with a molar ratio of TiC:Ti:Si:Al=2:1:1.05:0.15 into a graphite mold and sinter in a hot-press furnace with a protective atmosphere of A and r. The heating rate is 50°C / min, the sintering temperature is 1400°C, the pressure is 60MPa, and the temperature is kept for 6 hours. The density of the bulk material is 99.8%, Ti 3 AlC 2 The content is 99.5wt%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥750MPa, and the three-point bending strength σ b ≥370MPa, K IC ≥5MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com