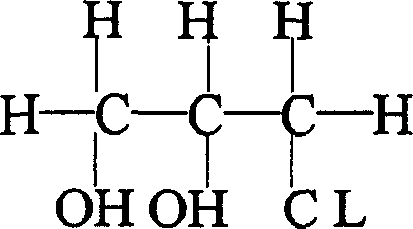

Method for removing 3-chlorine-1,2-propylene alcohol from aminopeptodrate

A technology of hydrolyzed protein and propylene glycol, which is applied in the field of purification of hydrolyzed protein, can solve the problems of high cost, destroy the taste of hydrolyzed protein, lose flavor of hydrolyzed protein, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with embodiment the present invention is described in further detail:

[0014] The present invention is achieved in this way, first adjust the pH value of the hydrolyzed protein according to the process parameters shown in Table 1, add five or six carbon sugars, then preheat the hydrolyzed protein to 60 ° C, and then within the specified time in Table 1, the hydrolyzed protein The temperature is raised to and maintained at the set temperature shown in Table 1, and finally, the temperature of the hydrolyzed protein is rapidly cooled to below 70°C. The obtained results are shown in Table 1.

[0015]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap