Manufacture of steel chimney, mounting process and special-purpose supporting frame

An installation process and support frame technology, applied in the field of steel chimneys, can solve the problems of undiscovered steel chimneys, difficult installation, high risk factor, etc., and achieve the effect of small construction difficulty, small installation risk factor, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

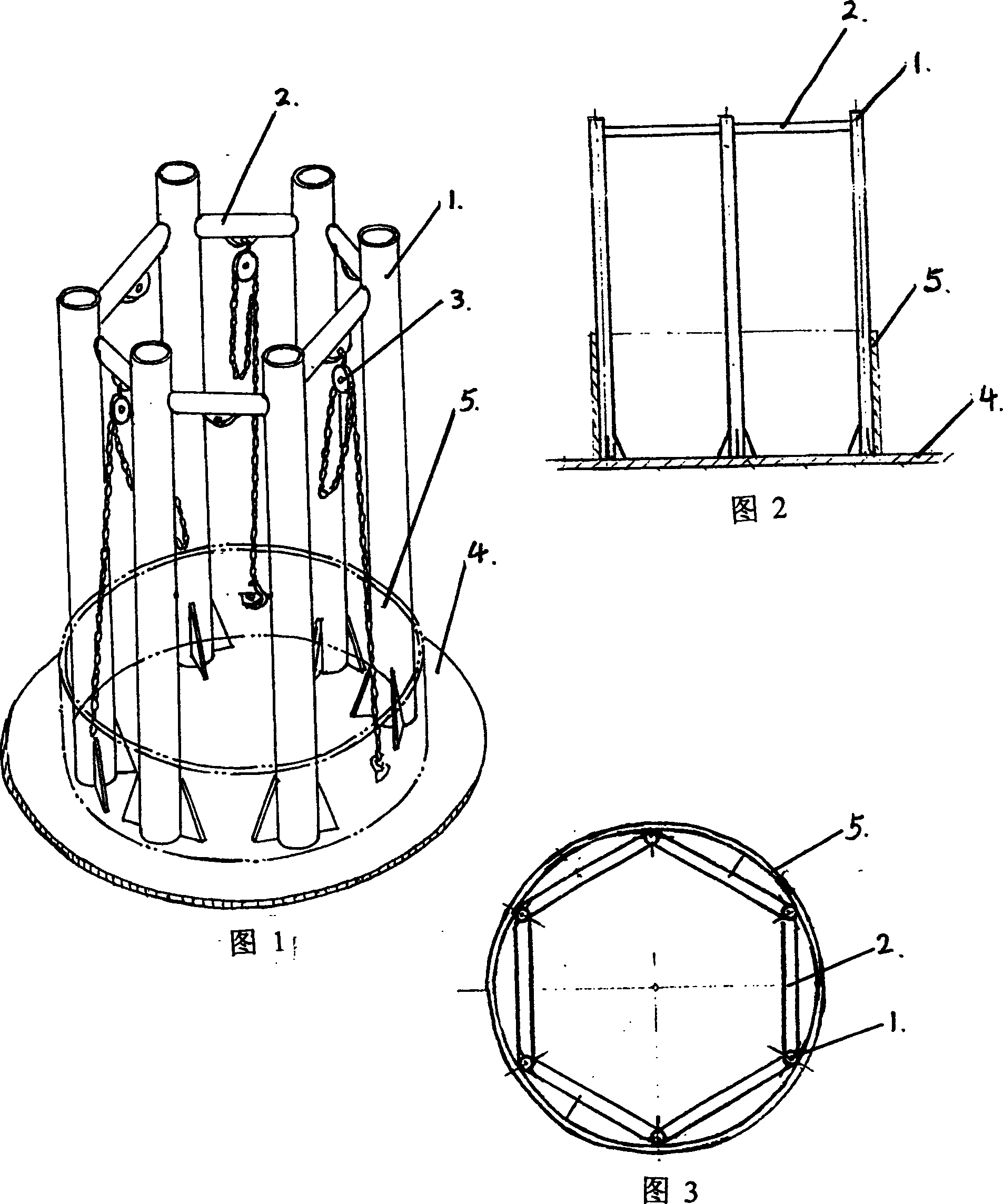

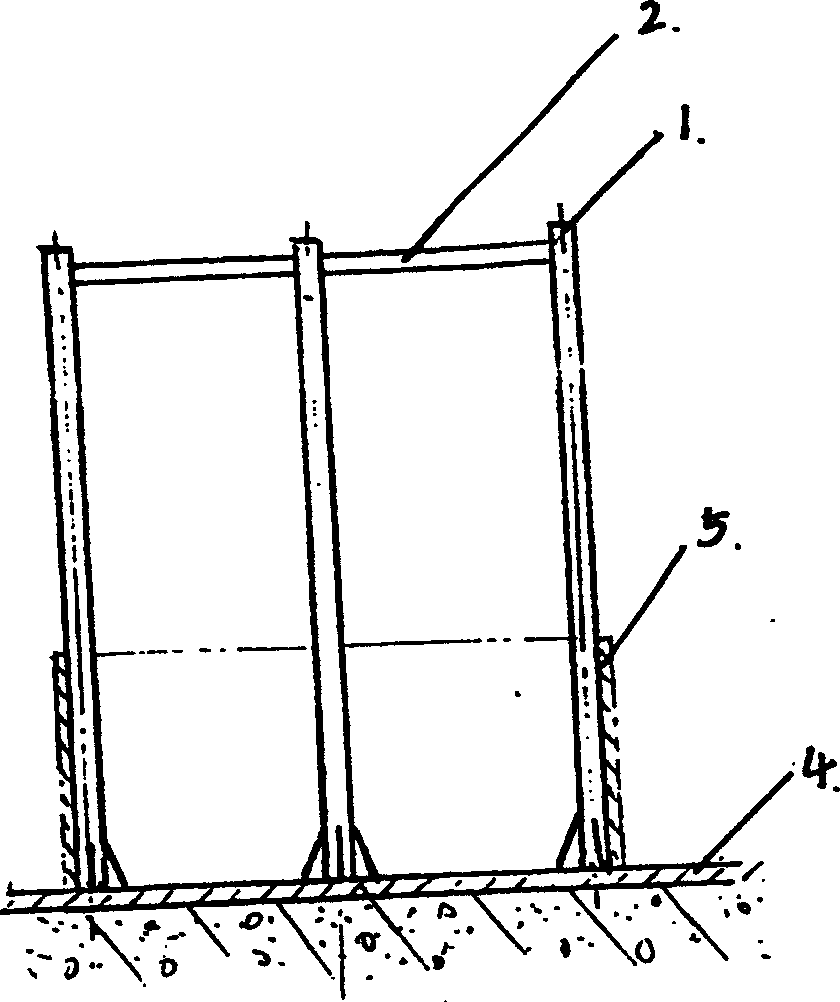

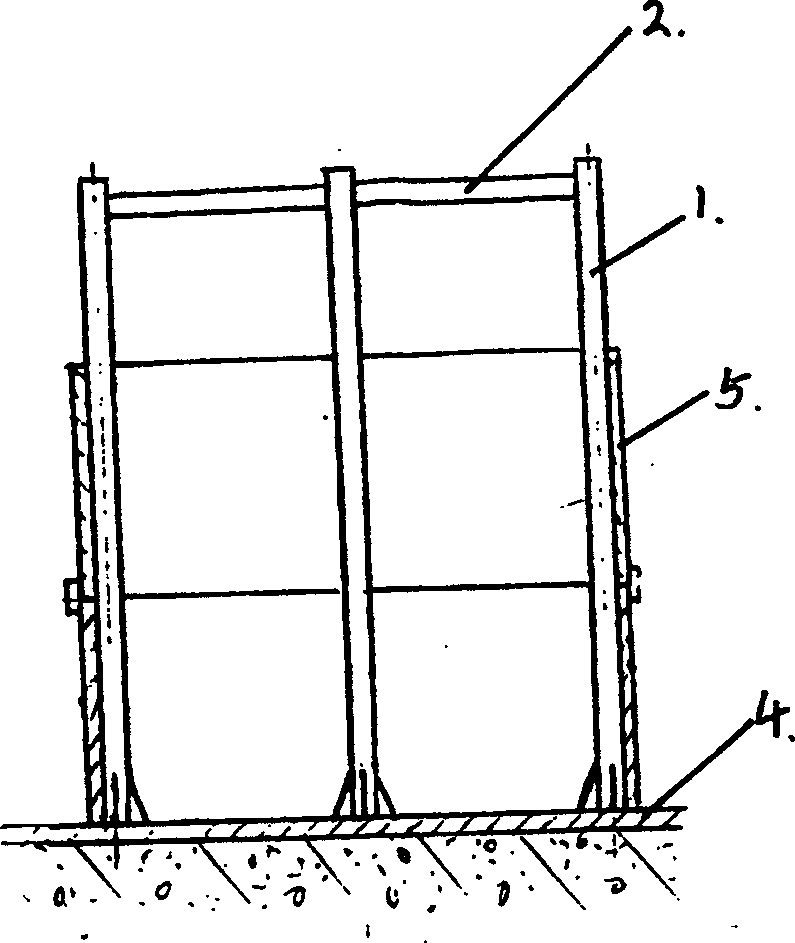

[0012] As shown in the drawings, the special support frame of the present invention is mainly composed of at least three vertical support columns 1, and the support columns 1 are arranged in regular polygons to form a regular polygon. The support columns 1 are used for The upward movement guide of the steel plate cylinder 5, the more the number, the better the guide, but the column distance between the support columns 1 should ensure the operating space. According to the requirements of general steel chimneys, the supporting pillars 1 can be designed as twelve, enclosing a regular dodecagon, and the diameter of the regular dodecagon is slightly smaller than the inner diameter of the steel chimney. A connecting rod 2 is welded between the upper part of the support column 1 and the support column 1, and a lifting guide chain 3 is hung on the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com