Trimethylolpropane ester-based plasticizer composition for polyvinyl chloride resin

A technology of trimethylolpropane and composition, which is applied in the field of trimethylolpropane ester-based plasticizer composition, and can solve problems such as weak chemical bonds and poor physical properties of trimethylolpropane ester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

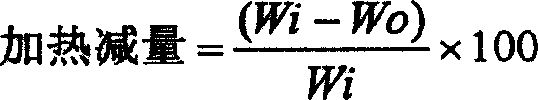

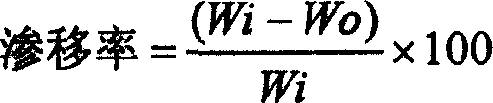

Image

Examples

Embodiment 1

[0030] (Preparation of plasticizer composition containing trimethylolpropane ester)

[0031] 268.36 grams of trimethylolpropane, 576.84 grams of 2-ethylhexanoic acid, 366.39 grams of benzoic acid, 50 grams of xylene as an entrainer substance, and 2.83 grams of tetraisopropyl titanate as a catalyst were added to a 2 In a 4-neck round bottom flask equipped with a stirrer and a condenser, the reaction was carried out for 10 hours by raising the temperature of the mixture to 220°C.

[0032] After the reaction, use a vacuum pump to evacuate the flask to 2mmHg at 200°C, remove unreacted acid, and neutralize the contents of the flask with 5% by weight of sodium hydroxide, wash and dry, and then add absorbent to the resultant , and filtered to obtain a mixture of trimethylolpropane esters.

[0033] The composition ratio of the composition is 18.21% by weight of trimethylolpropane-tri-2-ethylhexanoate, 42.82% by weight of 2,2-bis-2-ethylhexanoylmethoxybutyl benzoate, 31.23% by weight...

Embodiment 2

[0047] Trimethylolpropane esters and samples were prepared by the same method as in Example 1, except that the raw materials and quantities are shown in Table 1 below, and the results of measuring the esters for physical properties are shown in Table 2 below.

[0048] The composition ratio of the ester mixture is 25.65% by weight of trimethylolpropane tri-2-ethylhexanoate, 44.72% by weight of 2,2-bis-2-ethylhexanoylmethoxybutyl benzoate, 24.05% by weight of 2,2-bis-benzoylmethoxybutyl 2-ethylhexanoate, 3.47% by weight trimethylolpropane tribenzoate, and 2.11% by weight other ingredients.

Embodiment 3

[0050] Trimethylolpropane esters and samples were prepared by the same method as in Example 1, except that the raw materials and quantities are shown in Table 1 below, and the results of measuring the esters for physical properties are shown in Table 2 below.

[0051] The composition ratio of the ester mixture is 34.51% by weight trimethylolpropane tri-2-ethylhexanoate, 44.56% by weight 2,2-bis 2-ethylhexanoyl methoxybutyl benzoate, 17.52% by weight 2,2-bis-benzoylmethoxybutyl 2-ethylhexanoate, 1.38% by weight of trimethylolpropane tribenzoate, and 2.03% by weight of other ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com