Electric lamp with feedthrough comprising gauze

A technology of wire mesh and electric lamps, which is applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of tensile stress quartz glass cracking, corrosion of current conductors, unsafe bulbs, etc., to achieve enhanced lumens Keep the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

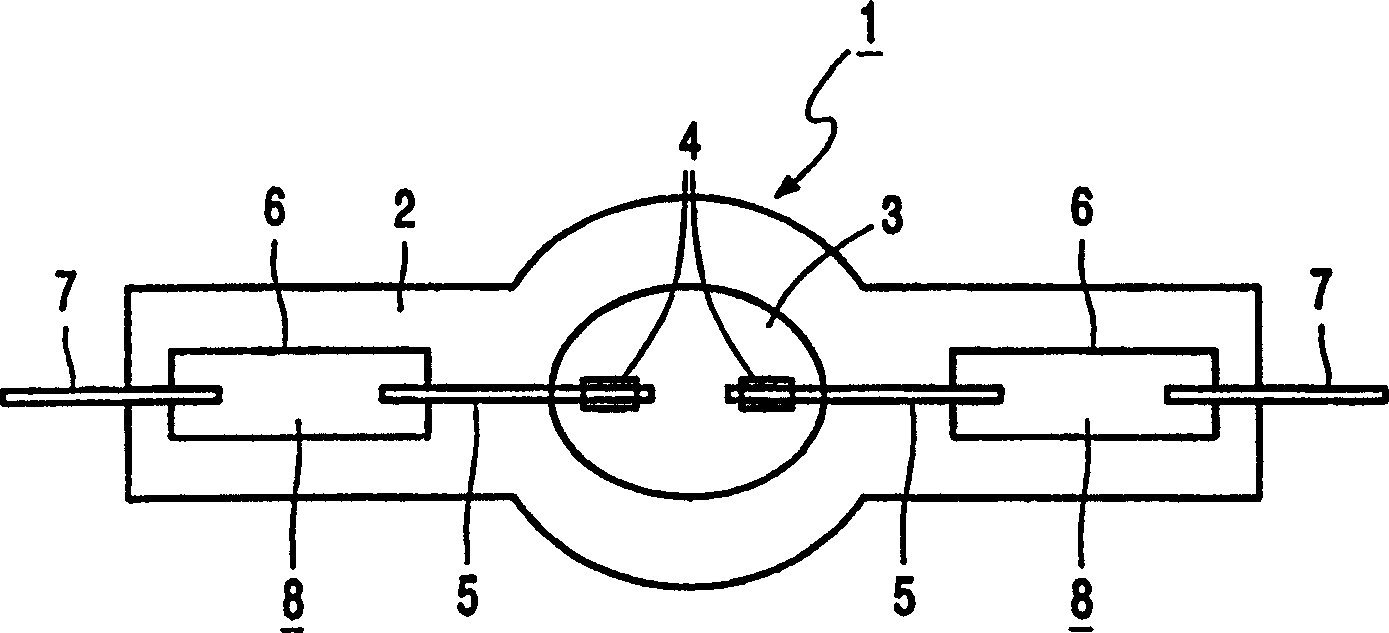

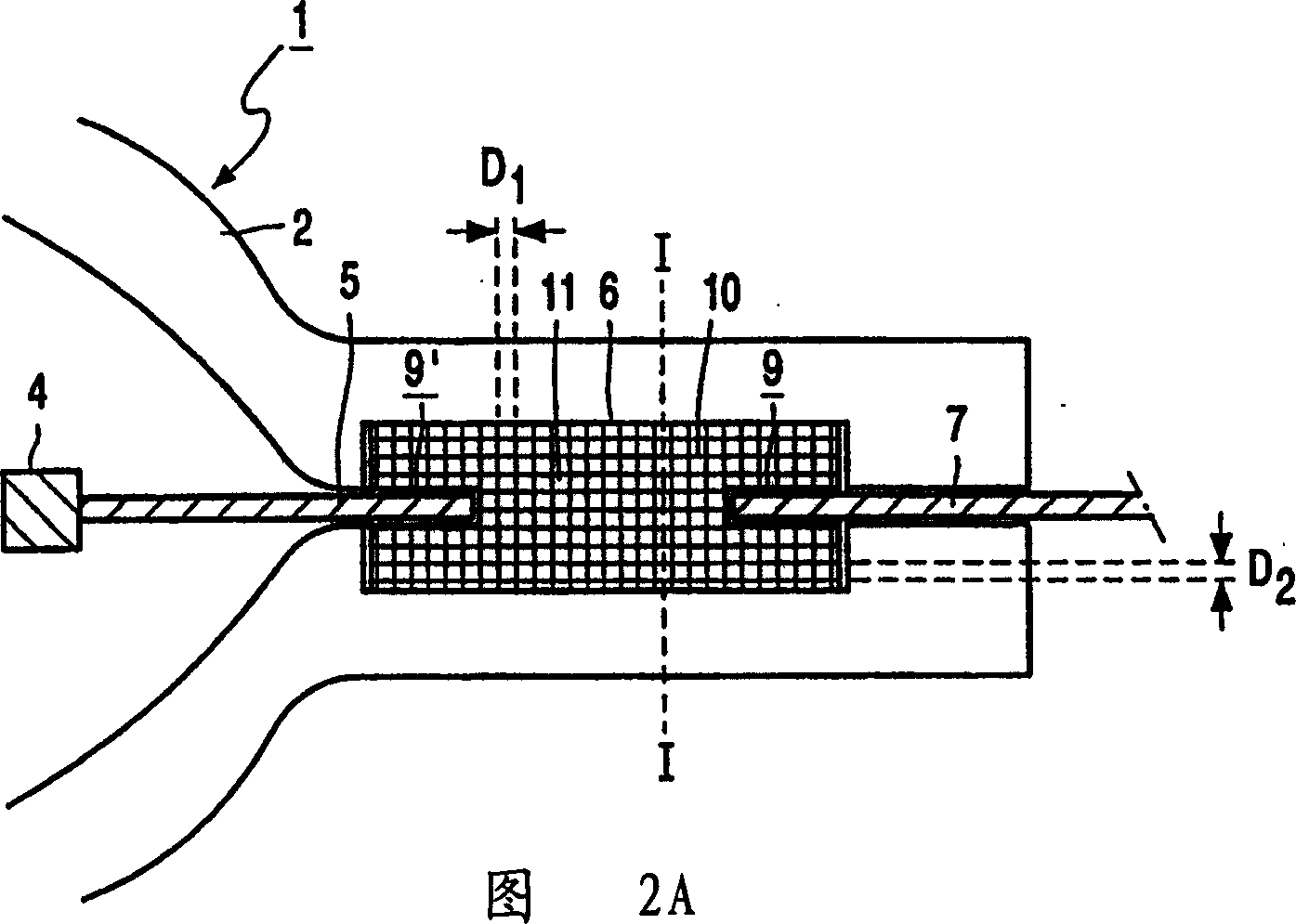

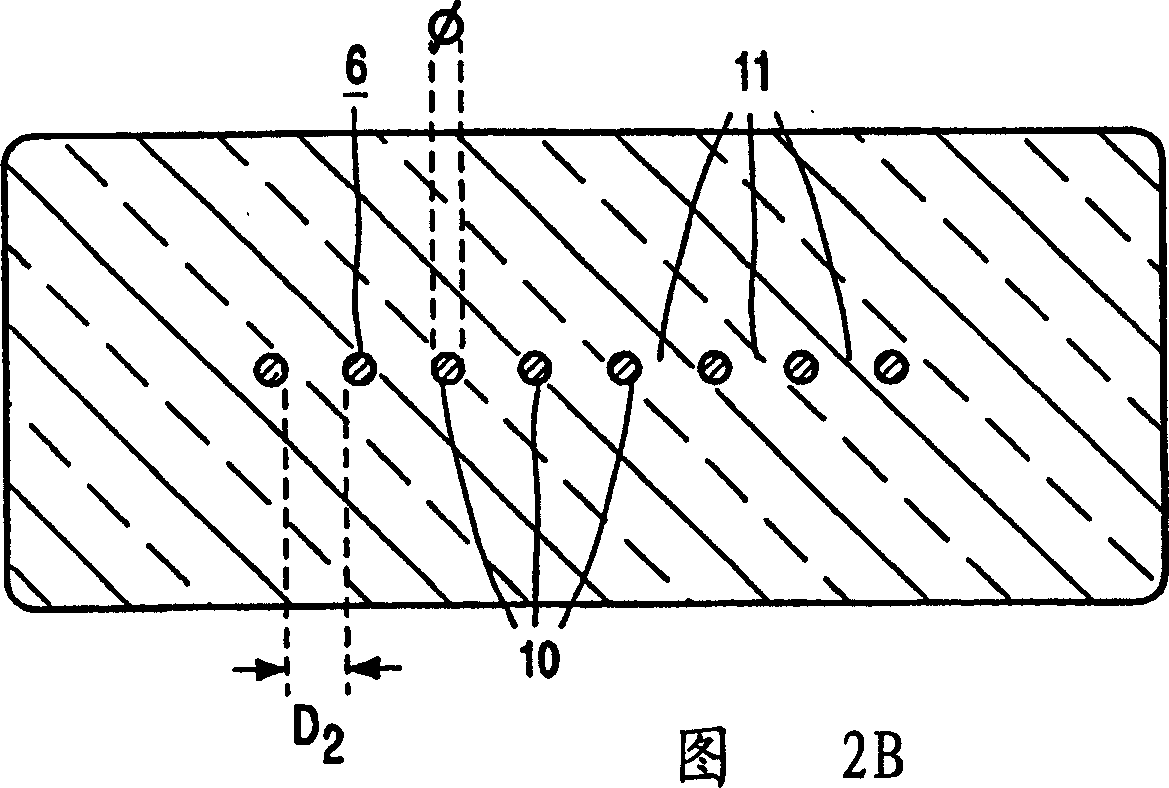

[0026] exist figure 1 In this case, the electric lamp is a high-pressure gas discharge lamp, which has a gas-tightly closed lamp vessel 1 and has a quartz glass wall 2 containing a space 3 . The electrical components 4 are connected to respective wire meshes 6 via inner current conductors 5, in figure 1 Among them, the wire mesh 6 is composed of 0.5% by weight of La 2 o 3 made of W. Electrical components 4 in figure 1In is a pair of electrodes, but it can also be replaced by an incandescent body. An inner current conductor 5 protrudes from the wall 2 of the lamp vessel 1 into the space 3 . A wire mesh is embedded in the wall 2 of the lamp vessel 1 and is connected, for example welded, to the respective outer current conductor 7, which is in the figure 1 Made of molybdenum.

[0027] The inner current conductor 5 and the electrical element 4 are made of tungsten with small amounts of constituents that regulate the crystal growth of tungsten, such as 0.01% by weight of K, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com