Adhesive supply device for automatically brushing adhesive

A glue-supplying device and automatic brushing technology, applied in clothing, shoe-bonding, shoe-making machinery, etc., can solve the problems of serious pollution, easy-drying of glue, uneven application, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

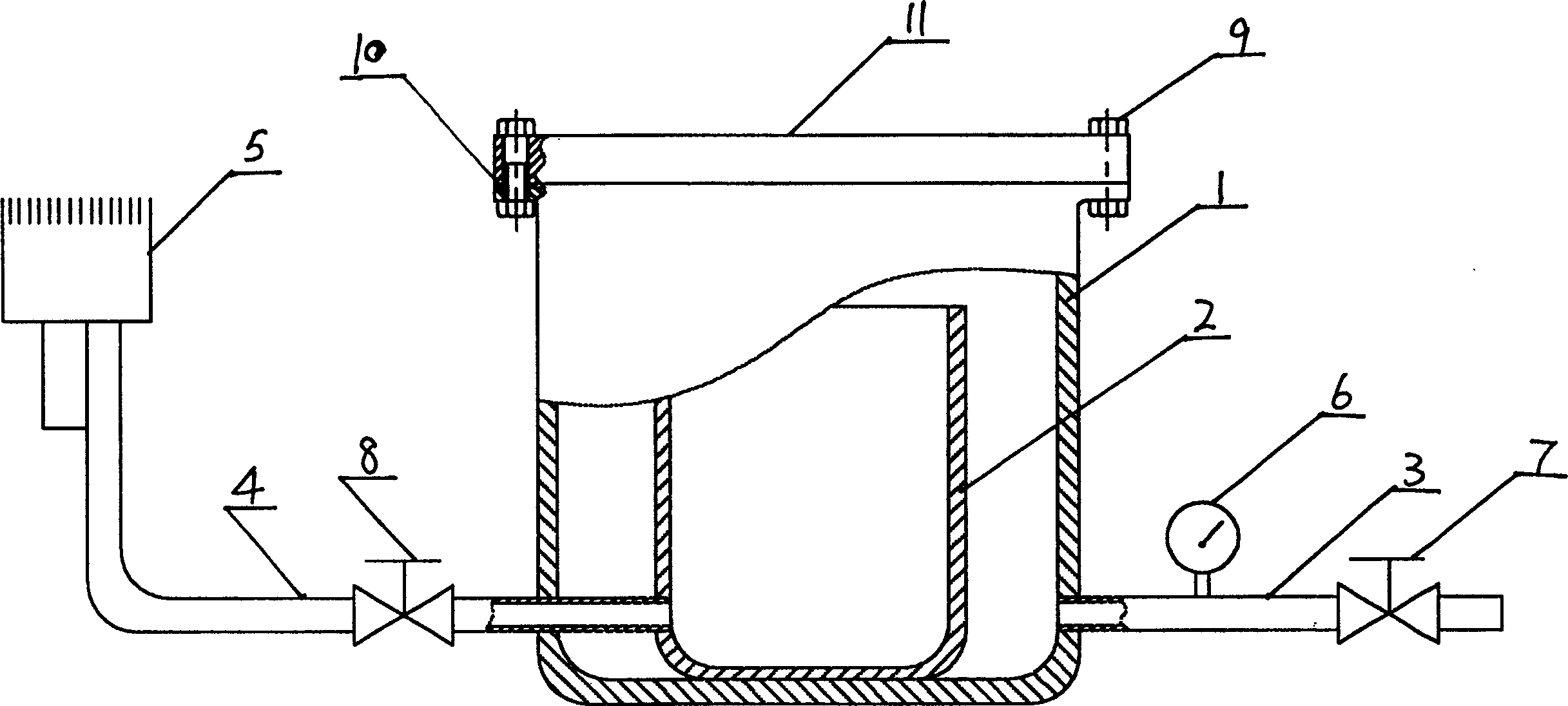

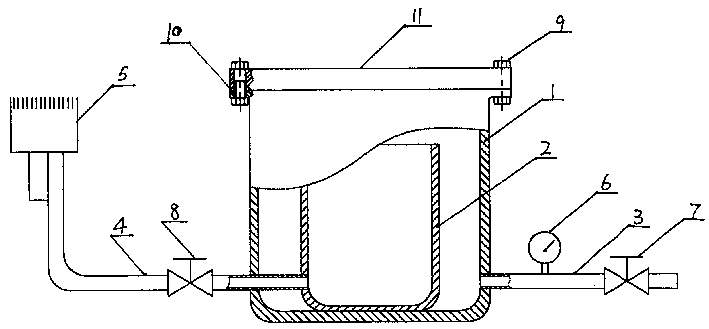

[0013] see figure 1 The present invention includes an airtight gas storage tank 1. The gas storage tank 1 is further equipped with a rubber storage tank 2. The height of the gas storage tank 1 is greater than that of the internal rubber storage tank 2. The tank body of the air storage tank 1 is connected with an air intake pipe 3 , the tank body of the glue storage tank 2 is connected with a glue outlet hose 4 , and the other end of the glue outlet hose 4 is connected with a brush 5 for brushing glue. The cover body 11 of the gas storage tank 1 is fixed to the top of the tank body of the gas storage tank 1 through screws 9, and a sealing ring 10 is arranged between the cover body 11 and the top of the tank body. The air intake pipe 3 is provided with a pressure gauge 6 and an air intake valve 7 , and the rubber outlet hose 4 is provided with a control valve 5 . When in use, add a certain pressure of gas into the gas storage tank 1, and the glue in the glue storage tank 2 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com