High performance wet process dust removal desulfurizing unit with three spinning parts

A wet desulfurization and dust collector technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of flue gas exhaust dryness, insufficient chemical solution, and insufficient desulfurization reaction that affect the desulfurization and dust removal effect, and achieve Effects that increase the chance of collision and the time it takes for chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

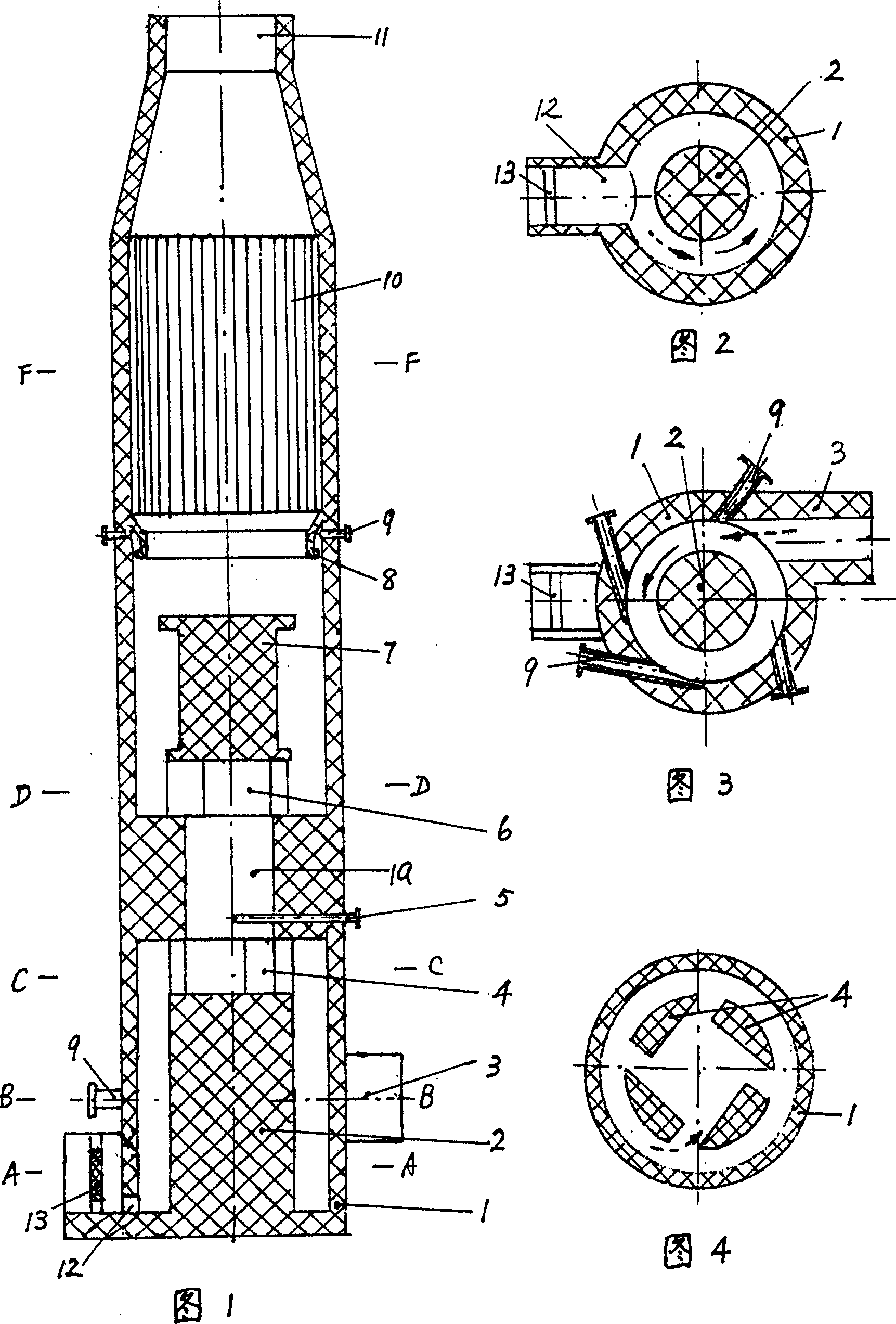

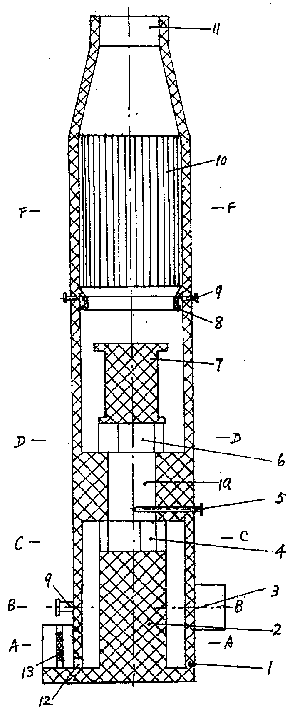

[0018] Embodiment 1. The three-rotation high-efficiency wet desulfurization dust collector of the present embodiment, its structure can be seen from Fig. 1, and it comprises a main tower 1 with inner tower 2 in its center of upright installation, the top of the main tower is provided with Flue gas outlet pipe 11, tangential flue gas inlet pipe 3 provided at the bottom and outlet pipe 12 for gray water and desulfurization slag, tangential chemical liquid nozzle 9 provided on the tower wall, swirl flow pipe provided at the top of the inner tower Centrifugal dehydration device 7, the main tower has a water retaining ring 8 on the inner wall above the top of the inner tower, and it is provided with a section on the air flow channel below the swirl centrifugal dehydration device to make the air flow centripetal swirl, rotate and rise And it turns into a double-swirl guide device with upward centrifugal swirl. Wherein the structure of the double swirl guide device can also be seen f...

Embodiment 2

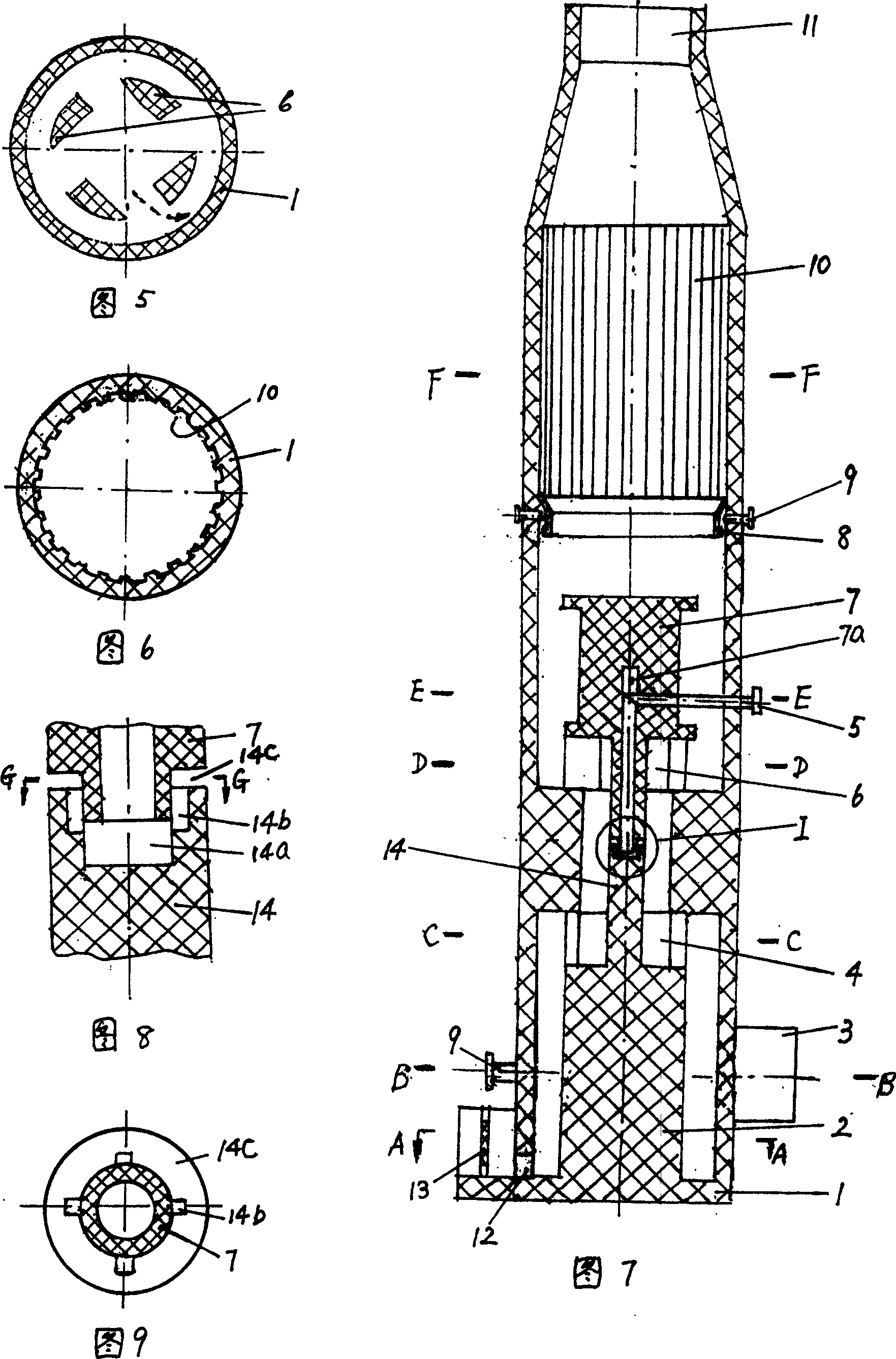

[0020] Embodiment 2. This embodiment can be seen from Fig. 1, and its difference with embodiment 1 is: the sump 10 that is provided with on the tower inner wall of main tower top. The structure of the tank can also be seen from Figure 6. It is a circle of inner grooves distributed on the inner wall of the top of the main tower, wherein each groove is vertical to the bottom surface to facilitate the downward flow of sediment and washing liquid .

Embodiment 3

[0021] Embodiment 3. This embodiment can be seen from Fig. 7, and it differs from Embodiment 1 or 2 in that: a central column 14 is also provided in the inner channel 1a of the double swirl guide device, and the upper end of the central column is connected to Cyclone centrifugal dehydration device 7, the lower end connects inner tower 2, and the outlet end of medicinal liquid pipe 5 can be directly arranged in the gap between cyclonic centrifugal dehydration device 7 and central column 14, and its medicinal liquid can be downward along central column. It captures fine and light fine ash in addition to toning liquid in the center, so that the dust removal effect is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com