Mother electric device, its producing method and electronic device and its producing device

A technology for electronic devices and manufacturing methods, which is applied in the direction of assembling printed circuits with electrical components, semiconductor/solid-state device manufacturing, and printed circuits connected with non-printed electrical components, which can solve the problem of cracks or cracks easily occurring on ceramic substrates, electronic Problems such as device detachment and easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

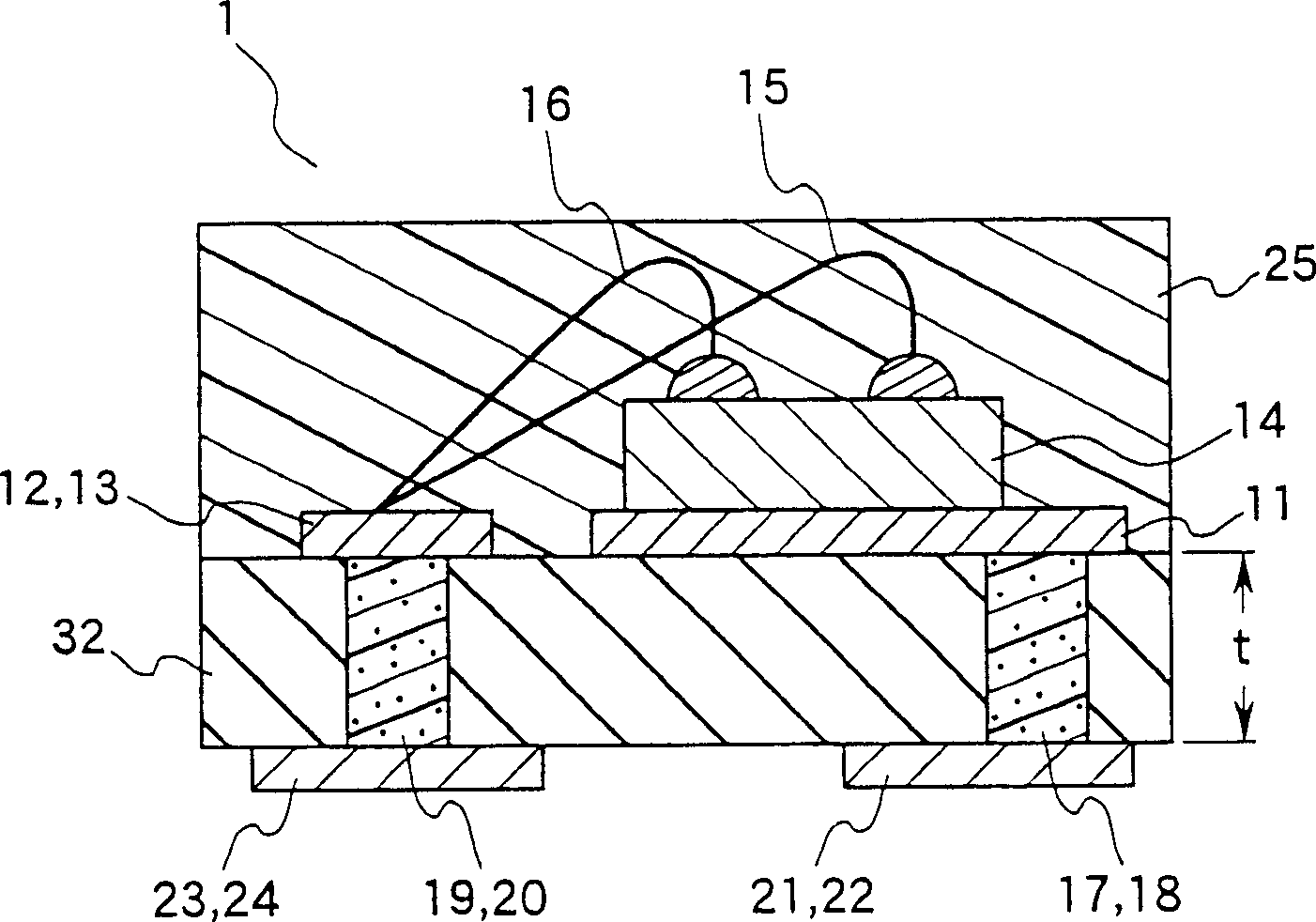

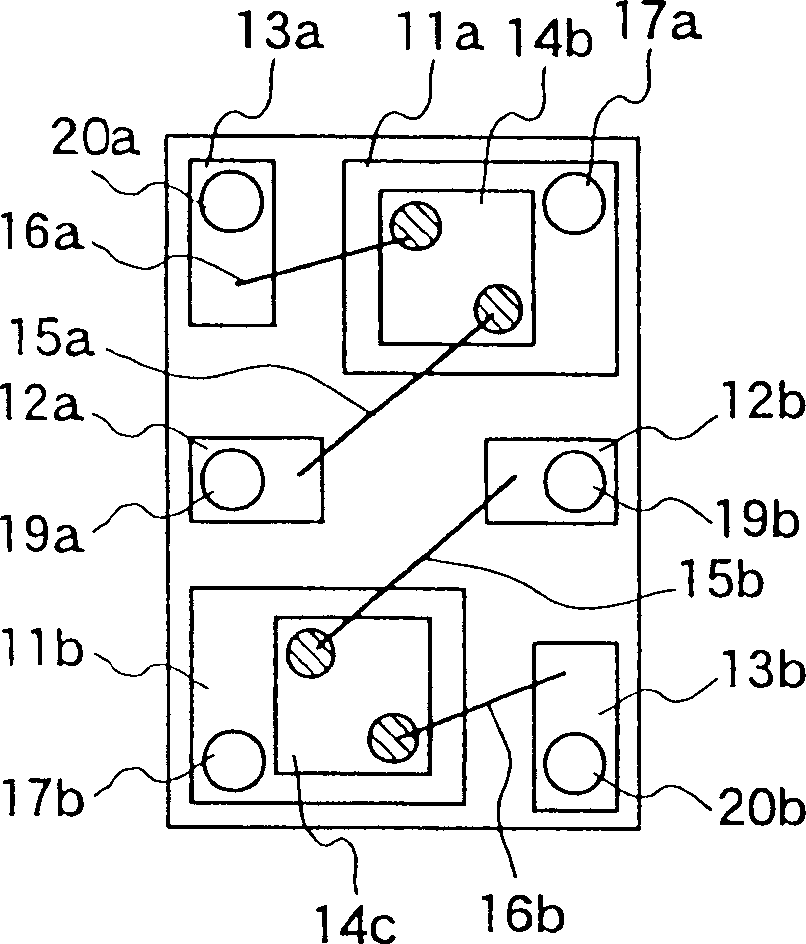

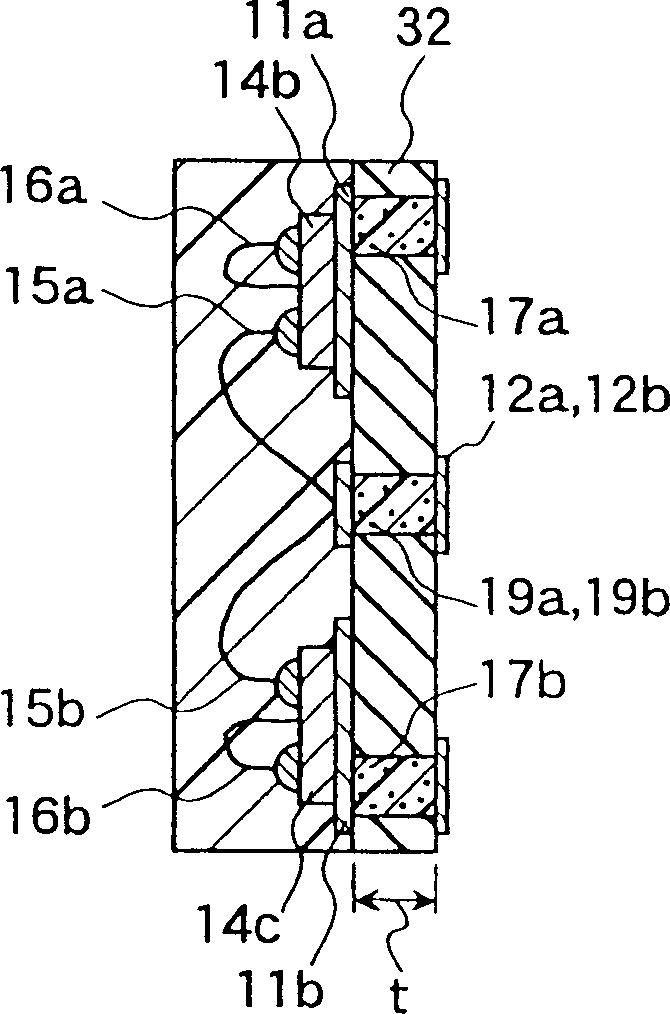

[0035] In the electronic device of the present invention, the metal thin film is preferably present on both the front side and the back side of the ceramic substrate. This is because the load pressure of both the upper mold and the lower mold can be buffered.

[0036] In addition, in the electronic device of the present invention, it is preferable that the metal thin film and the ceramic substrate are integrally sintered when the metal paste is printed on the green sheet as the raw material of the ceramic substrate and the green sheet is sintered. . This is because cost reduction can be aimed at. Furthermore, it is preferable from the viewpoint of cost that the metal paste is formed in the same process using the same material as the electrode formed on the surface and / or the back surface of the ceramic substrate. For the metal thin film, for example, tungsten can be used.

[0037] In addition, the thickness of the metal thin film is preferably in the range of 10 to 50 µm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com