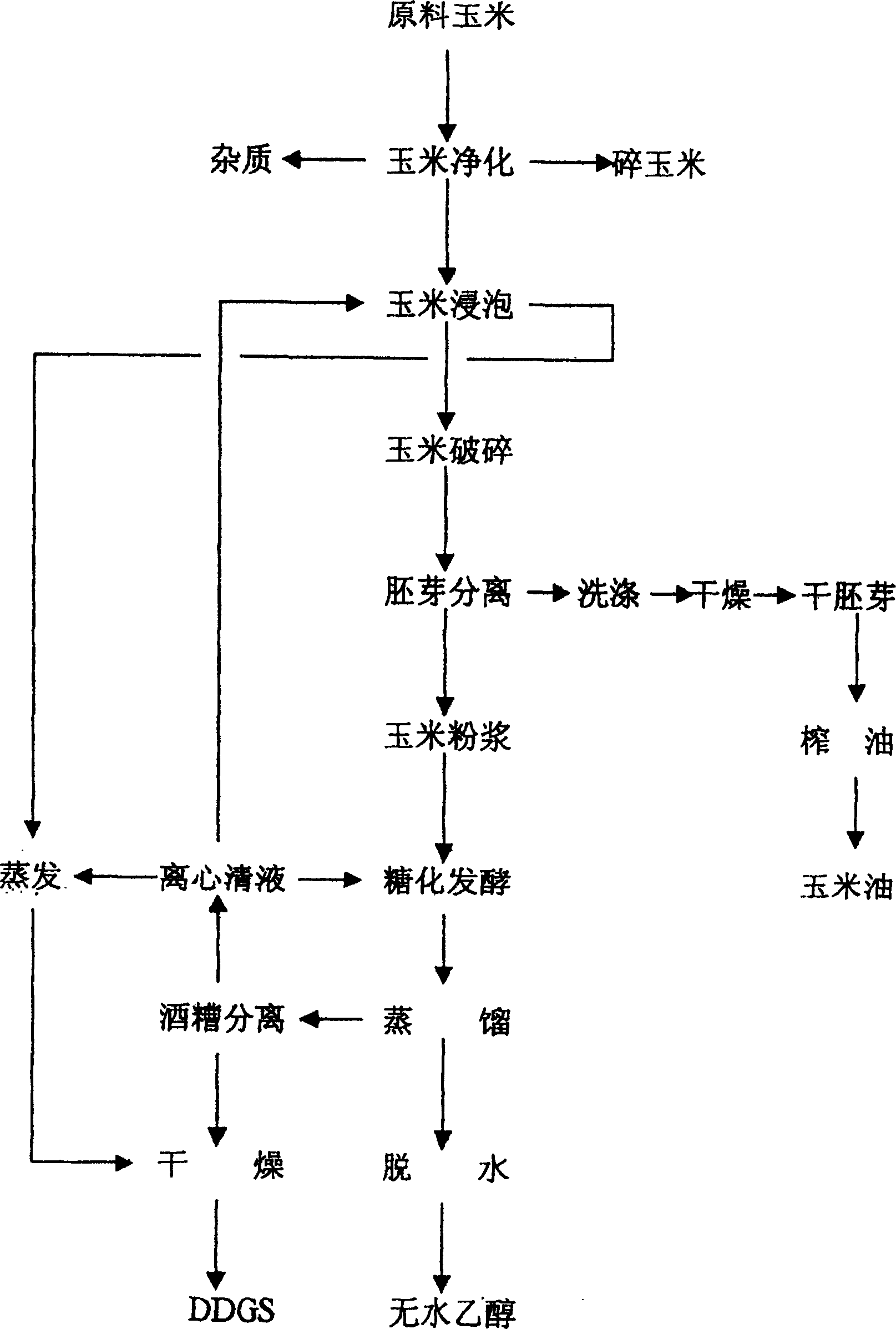

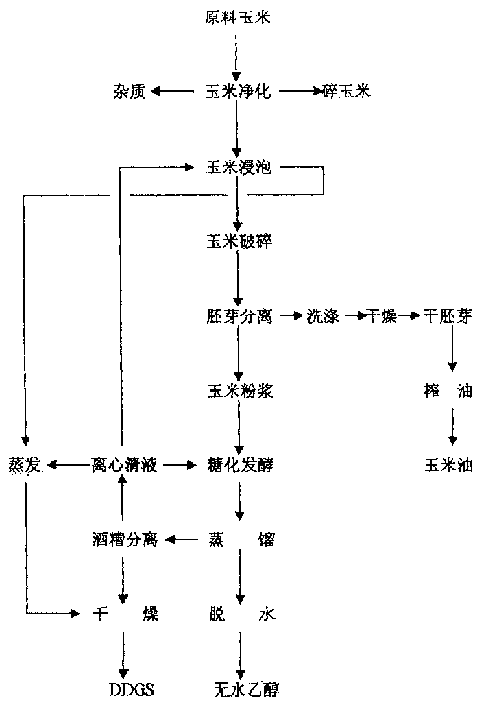

Improved wet method for producing fuel ethanol

A technology of fuel ethanol and wet process, which is applied in the field of wet degerming of corn, can solve the problems of ethanol production by wet process, long process flow, and loss of oil extraction, etc., so as to speed up water absorption and softening, reduce investment, increase The effect of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Put 50Kg of purified corn with a water content of 13.6% used in the production of the ethanol plant into an 80L cone soaking tank, add the centrifugal supernatant with a pH value of 3.5 and a solid content of 3.8% obtained from the ethanol plant site, and use a circulating pump And the circulation heater circulates the clear liquid, so that the temperature in the tank rises to 60 ° C, and keeps it for 4 hours. The soaking liquid is discharged, and the solid content is measured to be 5.8%. The soaked corn is crushed with a convex tooth mill , using the floating method to separate the germ, the yield of the germ is 6.1%. After the separation, the starch slurry is desaccharified and fermented, distilled, and dehydrated to produce absolute ethanol. The separated wet germ can be used for oil extraction after washing and drying.

Embodiment 2

[0017] Put 50Kg of purified corn with a water content of 14% used in the production of the ethanol plant into an 80L cone soaking tank, add the centrifugal supernatant with a pH value of 3.9 and a solid content of 4.0% obtained from the ethanol plant site, and use a circulating pump And the circulation heater circulates the clear liquid, so that the temperature in the tank rises to 62 ° C, and keeps it for 8 hours. The soaking liquid is discharged, and the solid content is measured to be 6.3%. The soaked corn is crushed with a convex tooth mill , using the floating method to separate the germ, the yield of the germ is 6.3%. After the separation, the starch slurry is desaccharified and fermented, distilled, and dehydrated to produce absolute ethanol. The separated wet germ can be used for oil extraction after washing and drying.

Embodiment 3

[0019] Put 50Kg of purified corn with a water content of 15.5% used in the production of the ethanol plant into the 80L cone soaking tank, add the centrifugal supernatant with a pH value of 3.6 and a solid content of 4.2% obtained from the ethanol plant site, and use a circulating pump And the circulation heater circulates the clear liquid, so that the temperature in the tank rises to 65 ° C, and keeps it for 12 hours. The soaking liquid is discharged, and the solid content is measured to be 6.8%. The soaked corn is crushed with a convex tooth mill , using the floating method to separate the germ, the yield of the germ is 6.6%. After the separation, the starch slurry is desaccharified and fermented, distilled, and dehydrated to produce absolute ethanol. The separated wet germ can be used for oil extraction after washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com