Reactor and method for gasifying and/or melting materials

A reactor and melt technology, applied in the gasification process, combustion method, gasification device details, etc., can solve the problems of sticking, difficult to remove deposits, interfering with the function of the circulating gas furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

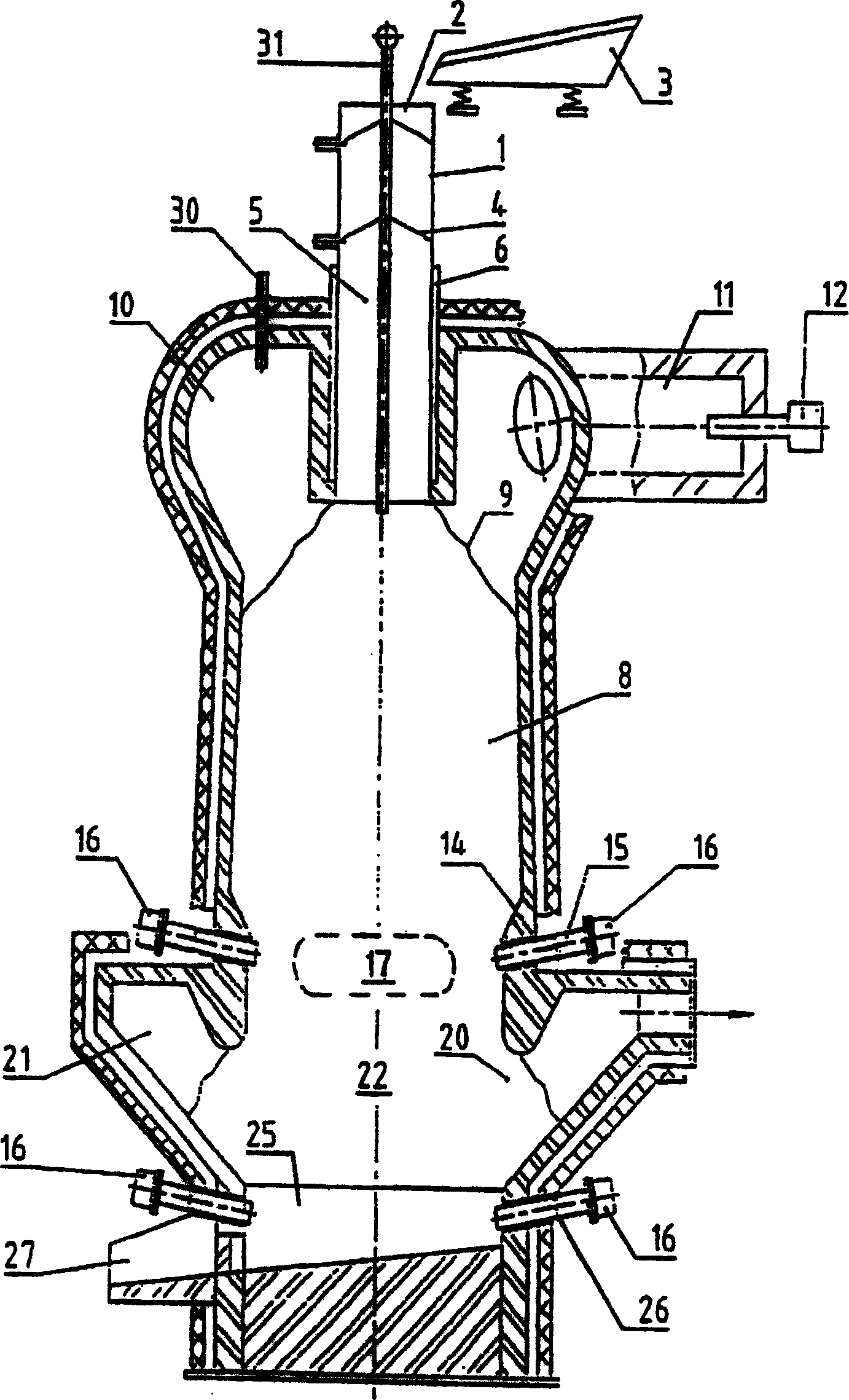

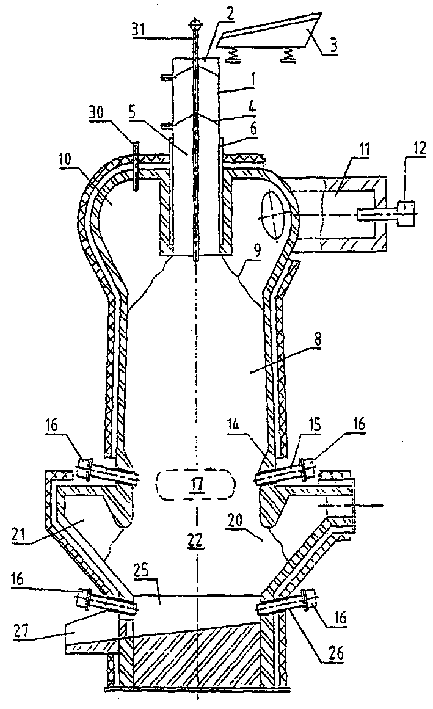

[0019] Refer below figure 1 A preferred embodiment of the reactor will be described. The details of the reactor are also described along with the method steps performed when processing waste fills including organic components. As can be seen in the appended claims, the process according to the invention is not necessarily associated with said reactor, but other equipment may be used as appropriate. The reactor and / or the process can be suitably modified when other packing materials are used (eg flexible arrangement and configuration of gas inputs and outputs, technical implementation of heating or cooling of reactor walls, etc.). In general, it is also possible to combine different fillers, for example adding high-energy feedstocks (eg organic waste with wood etc.) when oxidizing / melting non-organic fillers.

[0020] The upper end of the reactor shown in the figure has a feed section 1 with at least one feed opening 2 through which the filler material to be utilized for mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com