Manufacturing method of colour printed composite paper board for packaging box

A manufacturing method and packaging box technology, applied in wrapping paper, packaging, transportation and packaging, etc., can solve the problems of high price of high-end packaging products, inability to print on the front side, and affect the imaging of OPP film imprints, etc., so as to reduce the loss and waste of large areas , Improve production costs, improve equipment utilization and low labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

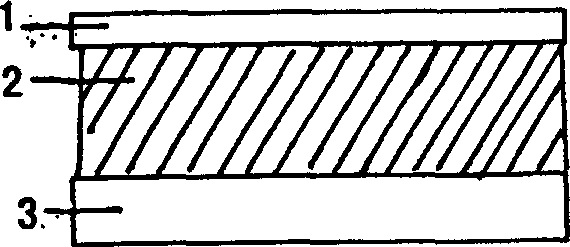

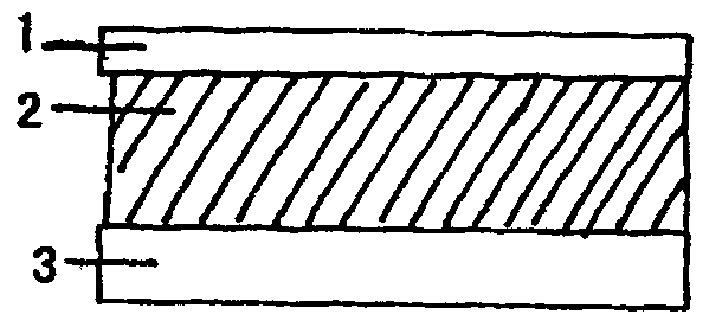

[0019] The layer structure relationship of the present invention is referred to accompanying drawing. The materials selected by the present invention are all available in the market, wherein the outermost layer is a roll-packed non-transparent polypropylene synthetic paper, and the surface of the non-transparent polypropylene synthetic paper can be printed in rolls with graphics, text, and color by a gravure printing machine. Common colored synthetic inks are used for printing. The non-transparent polypropylene synthetic paper layer 1 and the cardboard paper layer 3 are bonded together through the heating type polyester adhesive layer 2, see figure 1 . Wherein the cardboard layer 3 can be selected tea board paper, gray board paper or white board paper. figure 1 The composite paperboard shown is suitable for making color boxes with smaller volumes.

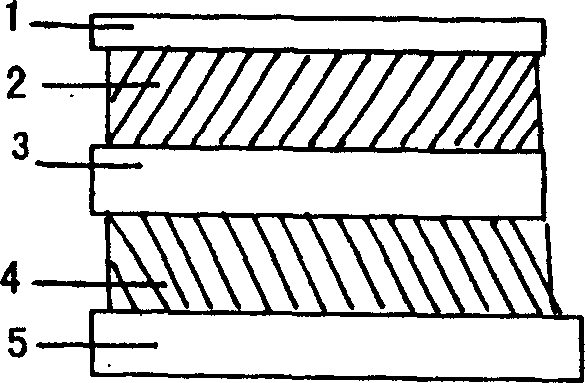

[0020] figure 2 Among them, a layer of corrugated cardboard 5 is pasted on the cardboard layer 3 by non-heating glue 4 . f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com