Restarting method for hydrogen alloy reaction system

A hydrogen storage alloy and restart technology, applied in climate change adaptation, adsorption machines, energy-saving heating/cooling, etc., can solve the problems of increasing the time required for restarting, increasing power consumption, and increasing the working time of suction devices, etc. , to achieve the effect of reducing power consumption, reducing working hours, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

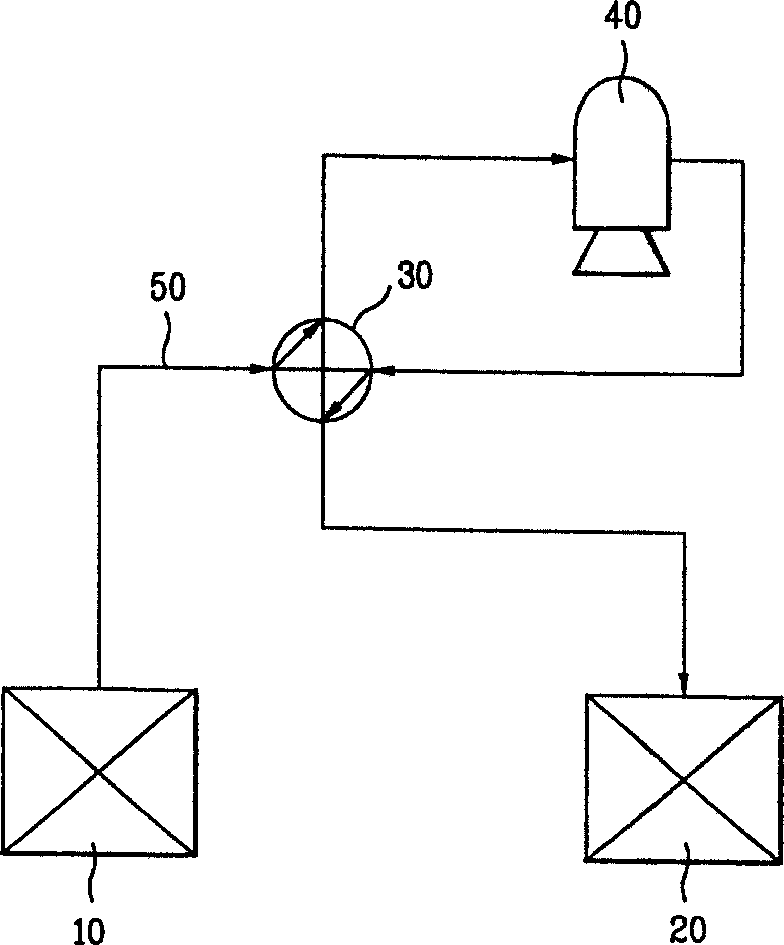

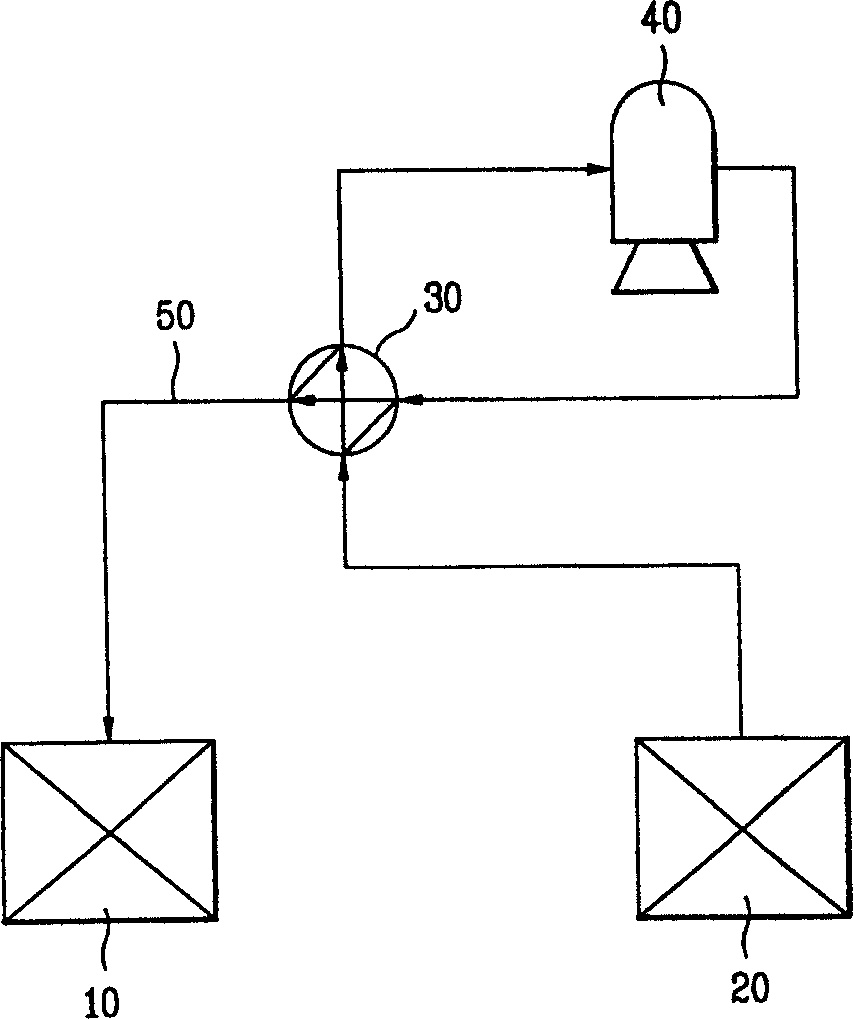

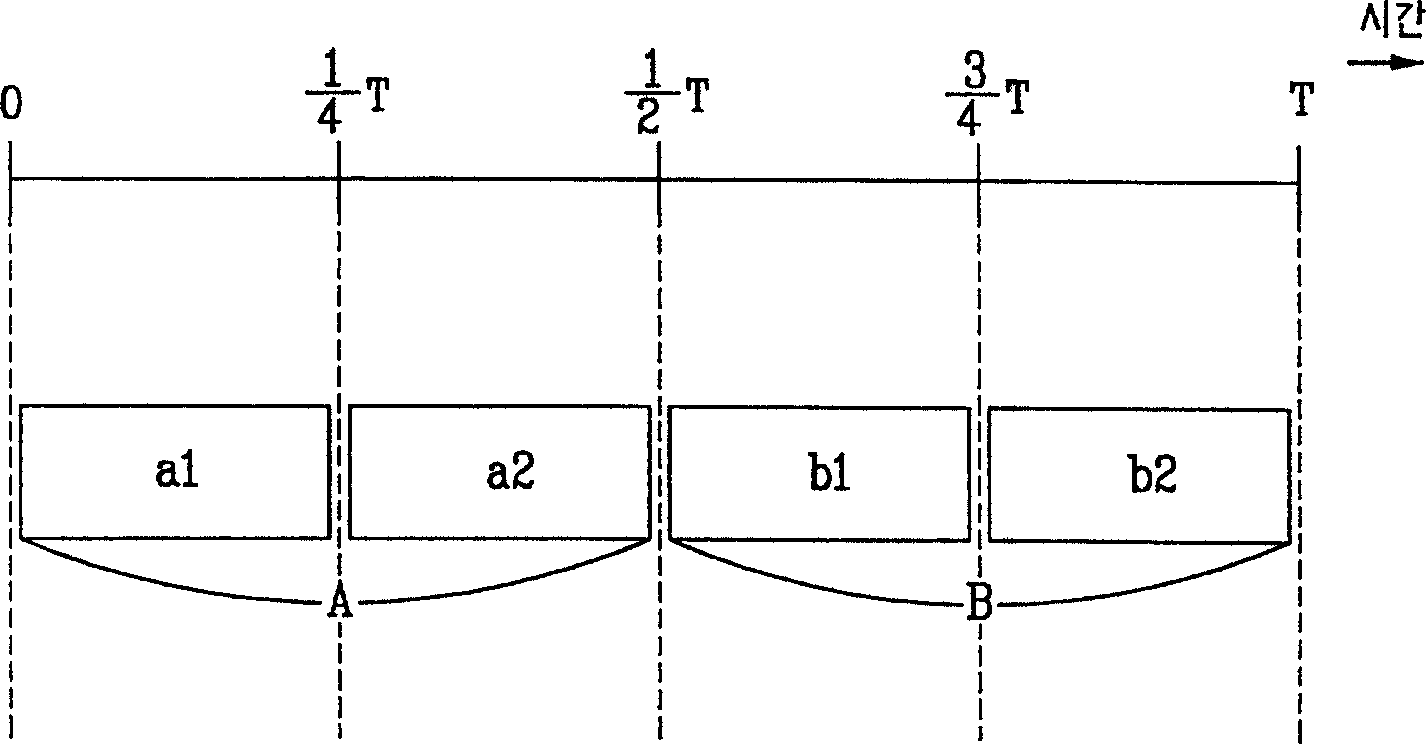

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: figure 2 It is a schematic diagram of the hydrogen absorption and hydrogen desorption cycle of the reactor according to the reaction interval of the restart method of the hydrogen storage alloy reaction system of the present invention. Referring to Figure 1 below, figure 2 The restart of the hydrogen storage alloy reaction system designed by the present invention will be described.

[0024] In the hydrogen storage alloy restart method of the present invention, when hydrogen is released from a reactor on a certain side of a pair of reactors 10 and 20 to the reactor on the other side, the entire interval from the starting point of hydrogen discharge to the complete hydrogen discharge point In the 1 / 2 interval, 80%-90% of the total amount of hydrogen moves, and in the other 1 / 2 interval, 10%-20% of the total amount of hydrogen moves, and this phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com