Angiosupport made of polyurethane and polyhydroxy fatty acid ester comixture and its preparation method

A technology of polyhydroxyalkanoate and vascular stent, which is applied in the field of biomedical engineering and can solve problems such as no literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

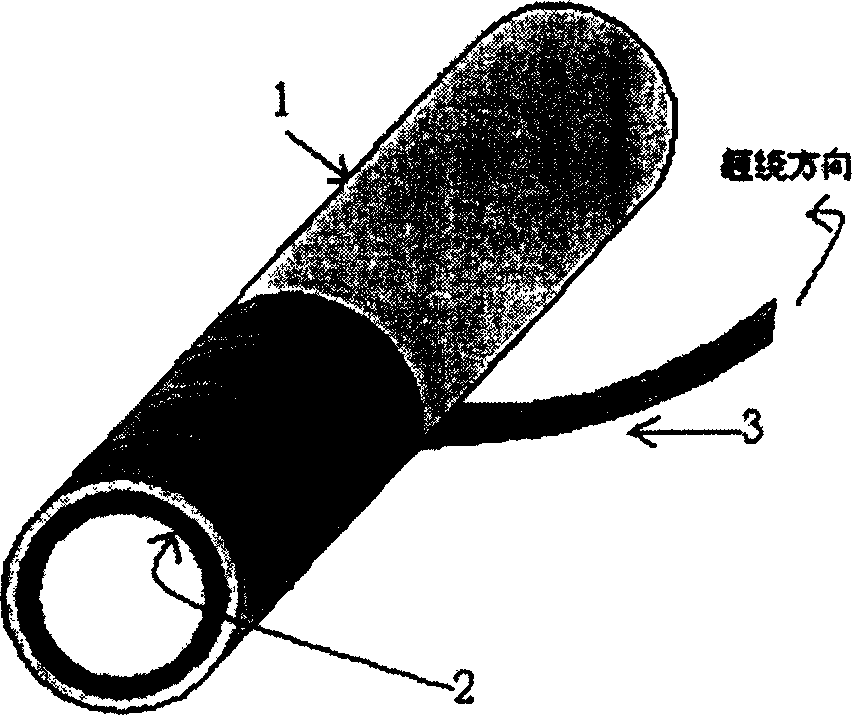

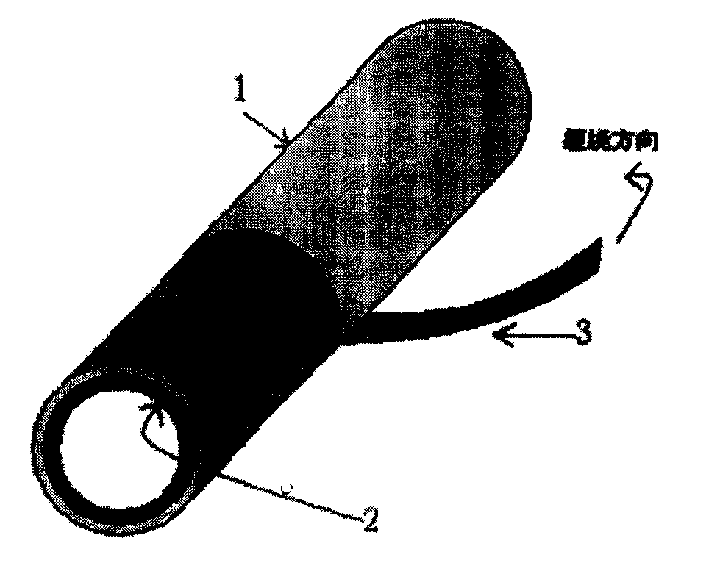

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of a PHB-HV / PU vascular stent with a diameter of 8 mm and a length of 50 mm

[0035] 1. Preparation of PHB-HV / PU solid film

[0036] ①, Mix PHB-HV and chloroform in a flask, mixing ratio: 1gPHB-HV plus 20ml chloroform, heat in a water bath, reflux for 15 minutes, and prepare a uniform solution. Mix PU and tetrahydrofuran in another flask, mixing ratio: 1gPU plus 20ml tetrahydrofuran, heat in a water bath, reflux for 15 minutes, and prepare a homogeneous solution.

[0037] ② Use a pipette to pipette the PU solution according to the proportion (the mass percentage of PU is 5%), slowly add it dropwise to the PHB-HV solution, stir while adding, condense and reflux for 15 minutes.

[0038] ③, using the method of cast film formation, cool the solution prepared in ② and pour it into a pair of evaporating dishes with a diameter of 10cm, fasten the upper and lower evaporating dishes, and slowly volatilize chloroform and tetrahydrofuran within 2 days , an...

Embodiment 2

[0054] Example 2: Preparation of a PHB / PU vascular stent with a diameter of 3 mm and a length of 10 mm

[0055] 1. Preparation of PHB / PU solid film

[0056] The preparation method is the same as the method for preparing the PHB-HV / PU solid film in Example 1, except that the PHB-HV / PU is replaced by PHB / PU, the percentage of PU is adjusted to 10%, and the diameter of the evaporating dish is adjusted to 6cm.

[0057] 2. Preparation of PHB / PU porous membrane

[0058] The preparation method is the same as the method for preparing the PHB-HV / PU solid film in Example 1, except that the PHB-HV / PU is replaced by PHB / PU, the percentage of PU is adjusted to 10%, and the diameter of the evaporating dish is adjusted to 6cm, the particle size of NaCl is adjusted to 200-300μm.

[0059] 3. Preparation of PHB / PU reinforcement

[0060] The preparation method is the same as the method for preparing the PHB-HV / PU reinforcing rib in Example 1, except that PHB-HV / PU is replaced by PHB / PU.

[...

Embodiment 3

[0063] Example 3: Preparation of a PHB-HH / PU vascular stent with a diameter of 12 mm and a length of 100 mm

[0064] 1. Preparation of PHB-HH / PU solid film

[0065] The preparation method is the same as the method for preparing the PHB-HV / PU solid film in Example 1, except that PHB-HV / PU is replaced by PHB-HH / PU, the percentage of PU is adjusted to 20%, and the diameter of the evaporating dish Adjusted to 19cm.

[0066] 2. Preparation of PHB-HH / PU porous membrane

[0067] The preparation method is the same as the method for preparing the PHB-HV / PU porous membrane in Example 1, except that PHB-HV / PU is replaced by PHB-HH / PU, the percentage of PU is adjusted to 20%, and the diameter of the evaporating dish is adjusted to 20%. Adjust to 19 cm, and adjust the particle diameter of NaCl to 200 to 300 μm.

[0068] 3. Preparation of PHB-HH / PU reinforcement

[0069] The preparation method is the same as the method for preparing the PHB-HV / PU reinforcing rib in Example 1, except tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com