Optical information recording medium and its manufacturing method

A technology for recording media and optical information, applied in the field of stampers for manufacturing substrates and their manufacturing, stampers and their manufacturing fields, and can solve the problem that the optical path difference cannot be obtained, the recording capacity of the optical information recording medium can be increased, and the laser optical path cannot be obtained. and other problems, to achieve the effects of easy grooving and substrate forming, reducing optical information, and improving recording density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Hereinafter, a method of manufacturing an optical information recording medium according to a first embodiment of the present invention will be described with reference to FIGS. 5 to 16 .

[0070] Described optical information recording medium can be manufactured with the following steps: the original disc groove process of forming required pattern on the original disc surface, the stamper production process of making stamper based on the original disc after the groove, duplicating with the stamper made Substrate production process of optical information recording medium substrate, and film formation process of forming various films on the replicated substrate.

[0071] [Master and stamper manufacturing method for substrate manufacturing]

[0072] First use Figure 5~ Figure 9 The method of manufacturing the master and the stamper for manufacturing the substrate 1 of the optical information recording medium of the present invention will be described. Such as Figure 5A...

Embodiment 2

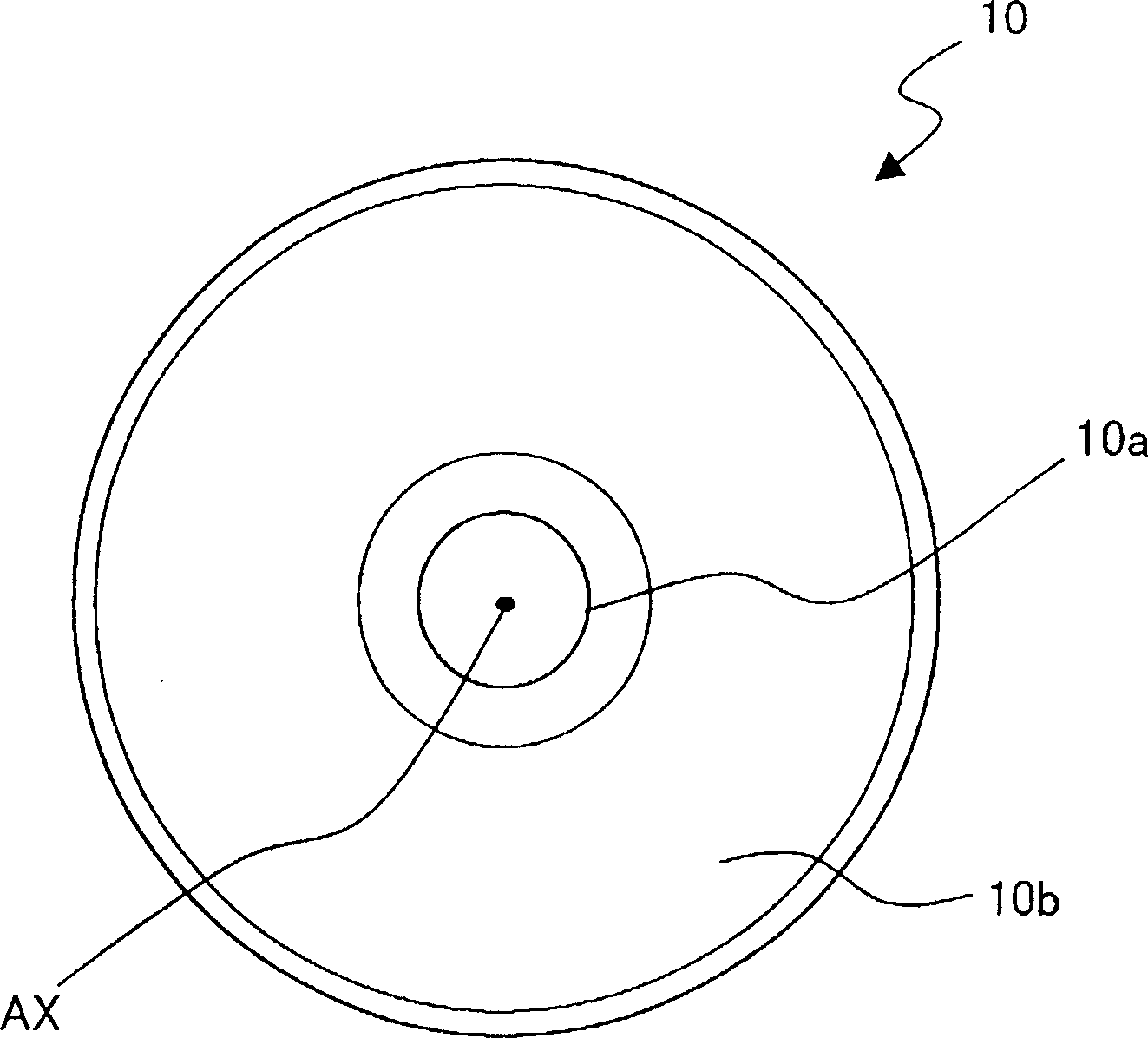

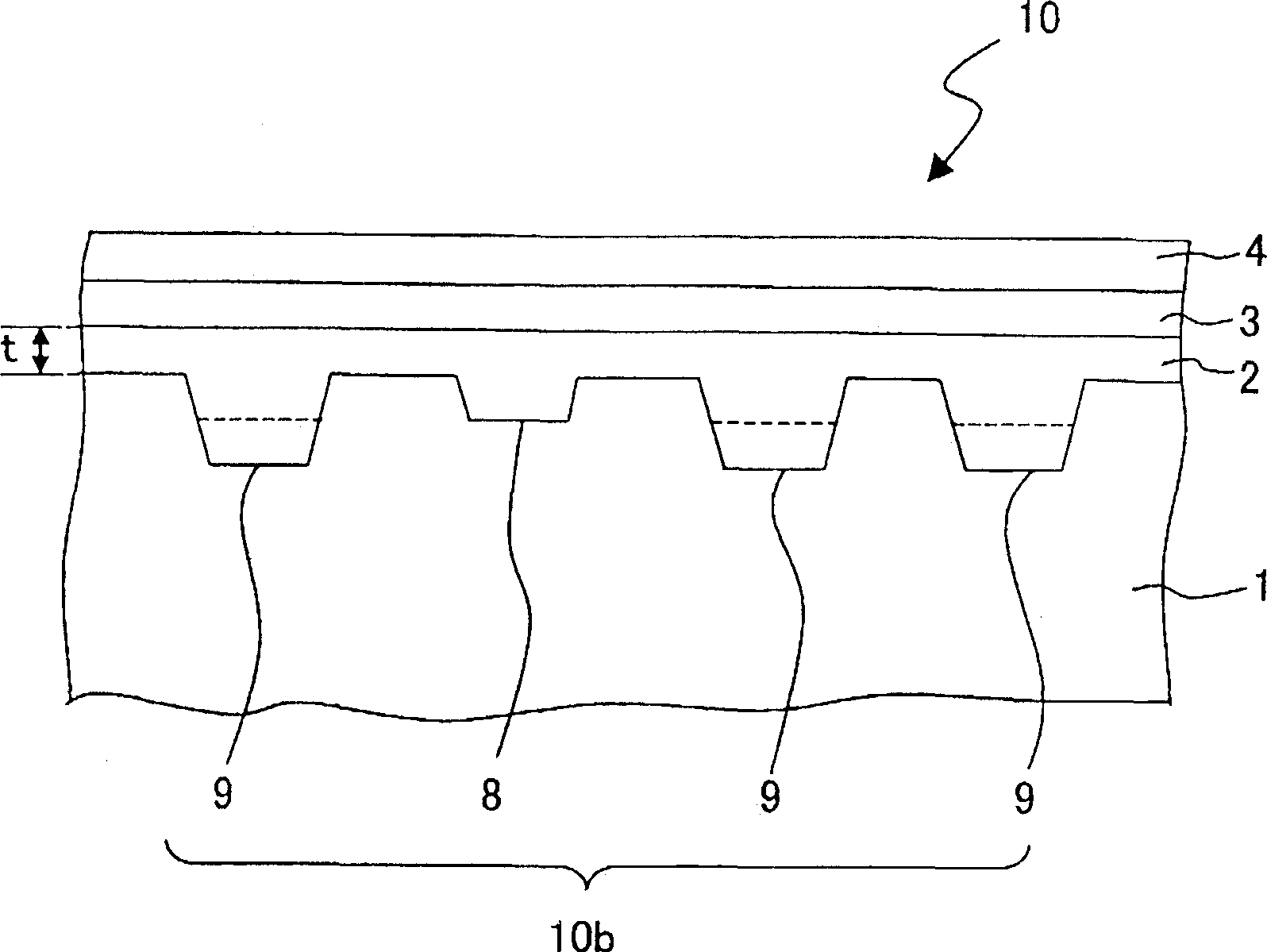

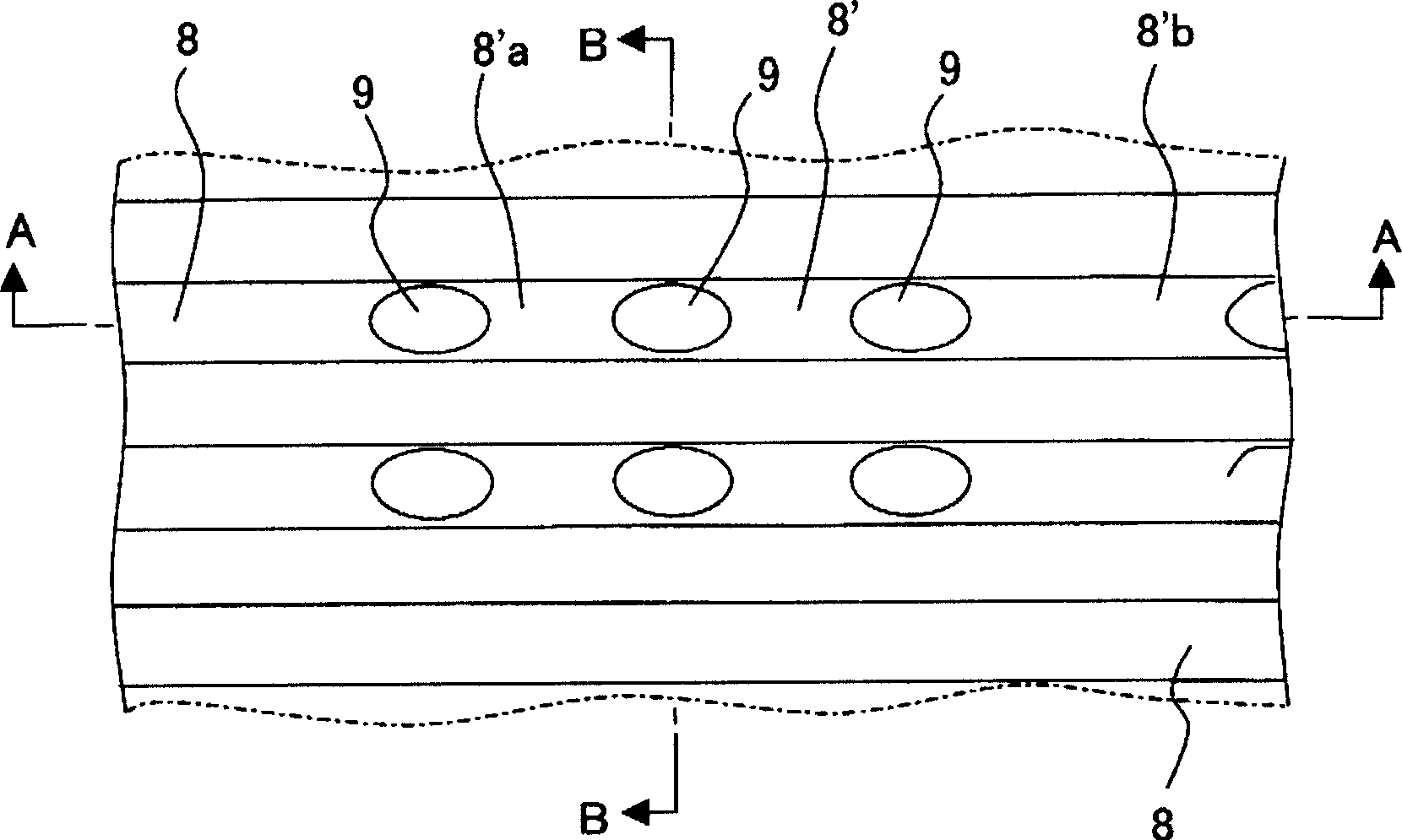

[0094] Use the following Figure 17 ~ Figure 1 9 illustrates the second embodiment of the optical information recording medium of the present invention. The optical information recording medium of this embodiment, such as Figure 17 As shown, the structure is the same as that of the first embodiment except that the predetermined format pattern formation area is composed of a medium information recording area 170b for recording medium information and a user information recording area 170c. The medium information recording area 170b is formed by a track with inner track information pits, and is formed within a radius of 23.9-24 mm based on the center AX'. On the other hand, the user recording area 170c is formed of only tracks, and is formed within a radius range of 21 to 23.9 mm and a radius of 24 to 58 mm based on the center AX'. Wherein, the track depth in the user recording area 170c is the same as the track depth in the part where no inner track information pits are forme...

example 1

[0098] use Figure 20 A modified example of Embodiment 2 will be described. The optical information recording medium of this modification example, such as Figure 20 As shown, it is an optical information recording medium in which a reflective layer 3 ", a recording layer 2 ", a protective layer 4 " and a cover layer 5 " are sequentially formed on the predetermined format pattern formation surface of the substrate 1 ", not from the substrate 1 " side but from the The surface layer 5 " side irradiates recording and reproduction with laser mode to carry out information recording and reproduction of the optical information recording medium. Regarding this optical information recording medium, since the bottom surface 201a of the optical track 201 and the bottom surface 202a of the inner track information pit 202 are formed flat , while the ratio dp' / dg' of the inner track information pit depth dp' to the track depth dg' in the substrate 1", and the maximum pit depth of the recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com