A kind of preparation method of composite modified Y molecular sieve

A compound modification and molecular sieve technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of incomplete utilization of rare earths, complicated molecular sieve process, low utilization rate of rare earths, etc., to improve the reaction activity and coke selectivity, product selectivity optimization, structural acidity and good surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

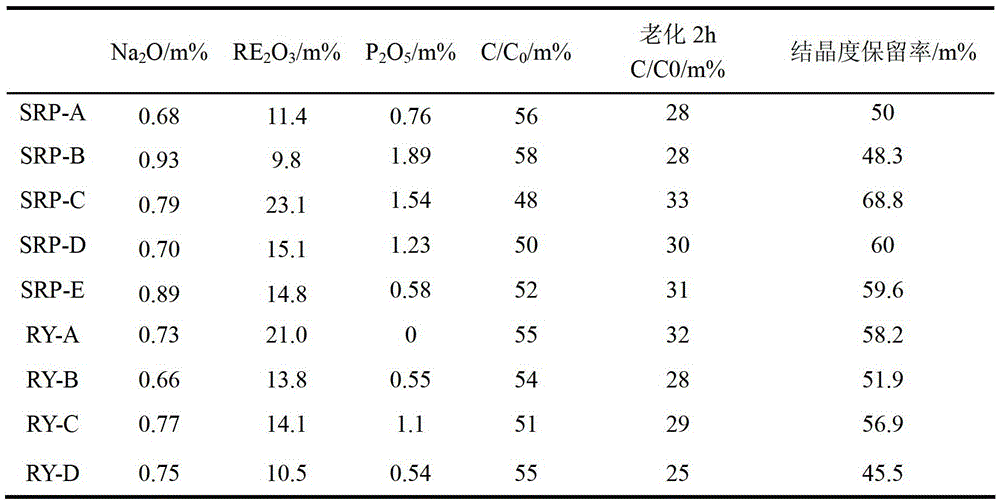

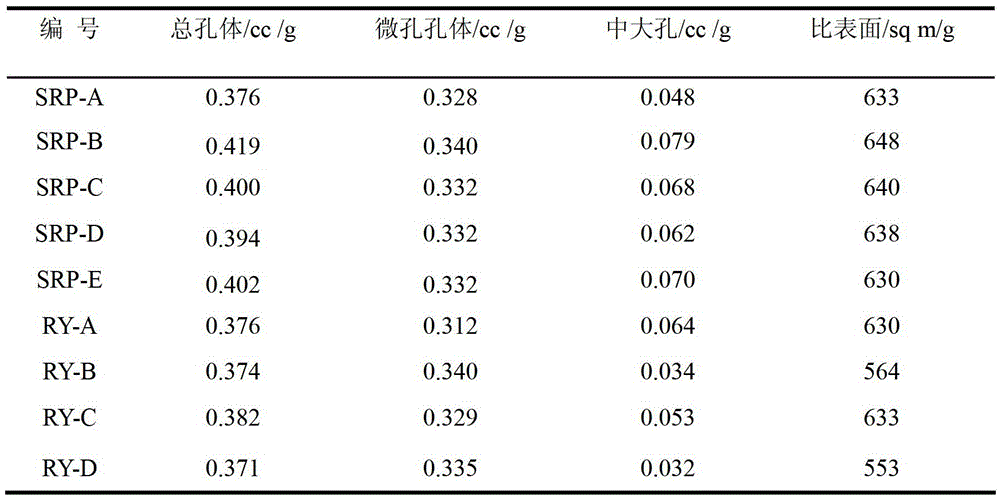

Embodiment 1

[0054] In the reaction tank, add 3000g (dry basis) NaY molecular sieve and 30kg deionized water, make a slurry, slowly add 1.8L of rare earth chloride, adjust the pH of the system to be between 3.5 and 4.0, heat up to 60 °C, and exchange for 1.0h. Add 360ml of silica sol, stir for 0.5h, add 51g of diammonium hydrogen phosphate, stir for 0.5h, filter, wash with water, dry and bake at 510°C for 2.0h with 100% water vapor. Designated as SRP-1. In the reactor, add SRP-1500g (dry basis) and 5L deionized water, make pulp, add 50g ammonium sulfate, adjust the pH of the system to 3.5, heat up to 90°C, exchange for 0.5h, filter, wash, dry, and prepare The rare earth Y molecular sieve active component of the present invention is obtained, which is recorded as SRP-A.

Embodiment 2

[0056] In the reaction tank, add 3000g (dry basis) NaY molecular sieve and 30kg deionized water, beat, slowly add 1.2L of rare earth nitrate, adjust the pH of the system to be between 4.0 and 4.5, heat up to 90℃, exchange for 1.0h, add 800ml Water glass, stirred for 0.5h, added 133g of ammonium dihydrogen phosphate, stirred for 1.0h, filtered, washed with water, dried, calcined at 100% water vapor and 500 ℃ for 2.5h. Designated as SRP-2. In the reactor, add SRP-2500g (dry basis) and 5L deionized water, make pulp, add 75g ammonium sulfate, adjust the pH of the system to 3.8, heat up to 90°C, exchange for 0.5h, filter, wash, dry, and prepare The rare earth Y molecular sieve active component of the present invention is obtained, which is denoted as SRP-B.

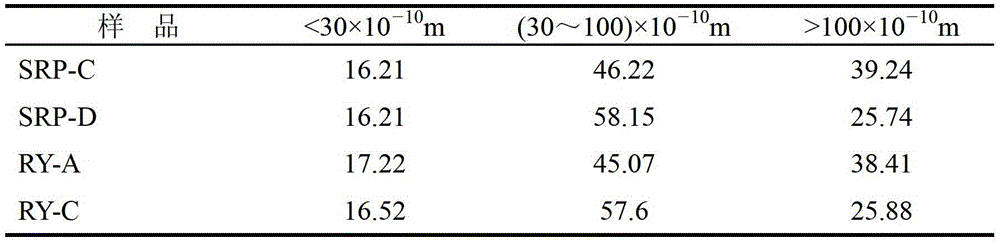

Embodiment 3

[0058] In the reaction tank, add 3000g (dry basis) NaY molecular sieve and 30kg deionized water, make a slurry, slowly add 3.5L lanthanum chloride, adjust the pH of the system to 3.5~4.0, and exchange at 90℃ for 1.0h, then add 470g water glass , stirred for 0.5h, added 115g of ammonium phosphate, stirred for 0.5h, filtered, washed with water, dried by air flow, and then sent to the roasting furnace, roasted at 500 ℃ for 1.5h. Designated as SRP-3. In the reactor, add SRP-3500g (dry basis) and 5L of deionized water, make pulp, add 50g of ammonium chloride, adjust the pH of the system to 3.8, heat up to 90°C, exchange for 0.5h, filter, wash, dry, prepare The rare earth Y molecular sieve active component of the present invention is obtained, which is denoted as SRP-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com