Base frame

A pedestal and frame technology, which is applied in the frame/frame structure, substation/switchgear frame, rod connection, etc., can solve the problems of heavy weight, high cost, high construction, manufacturing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

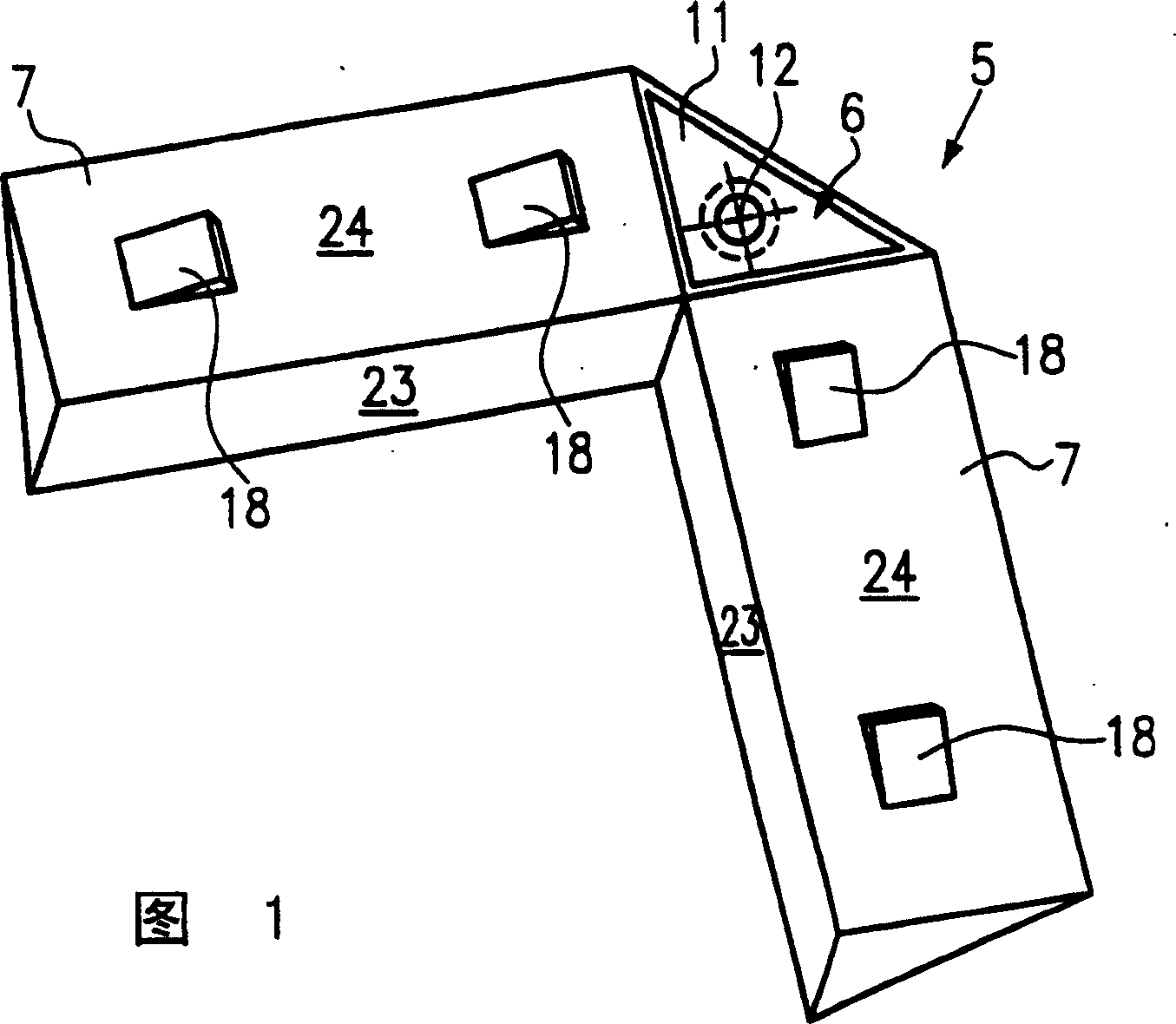

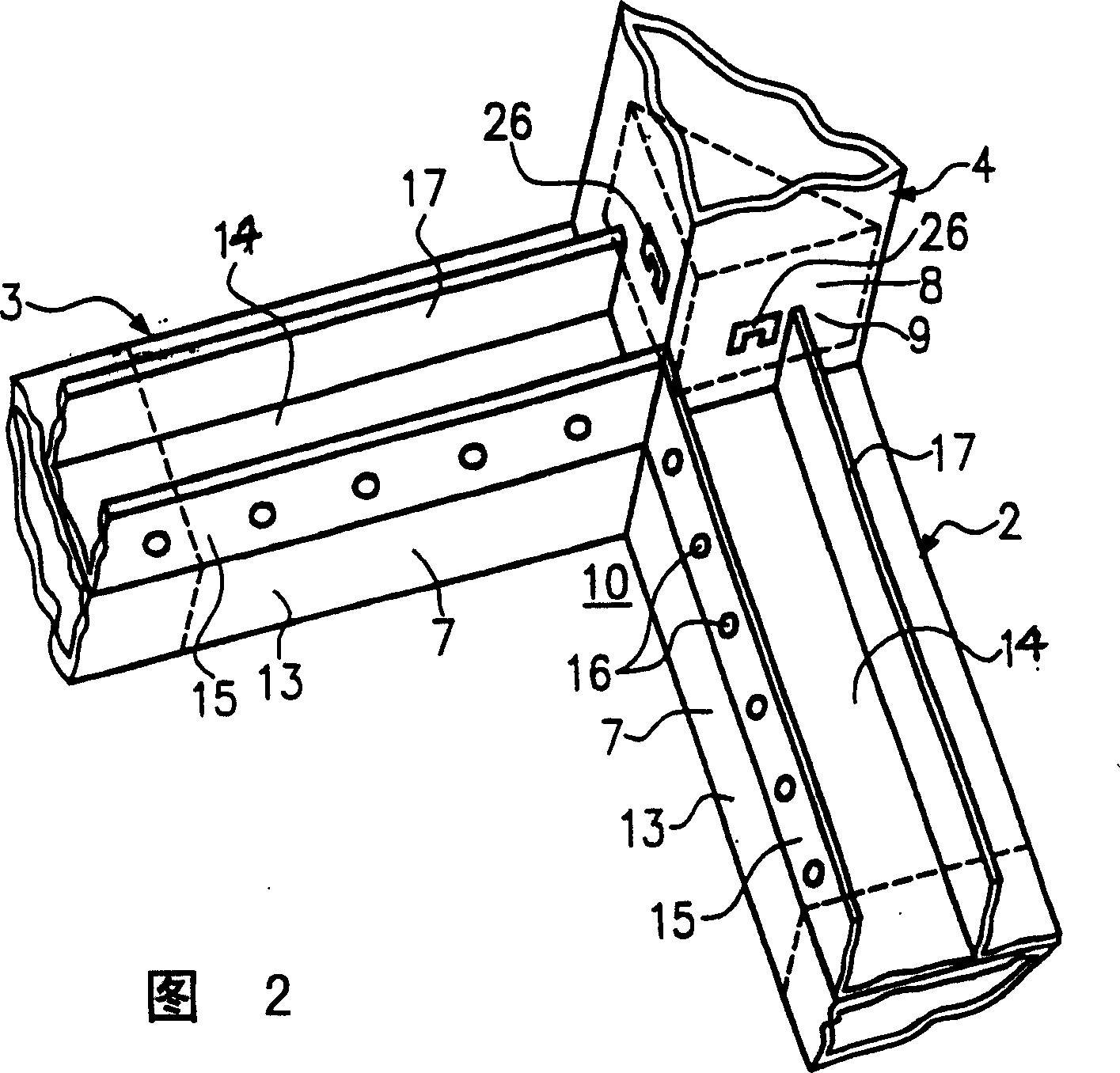

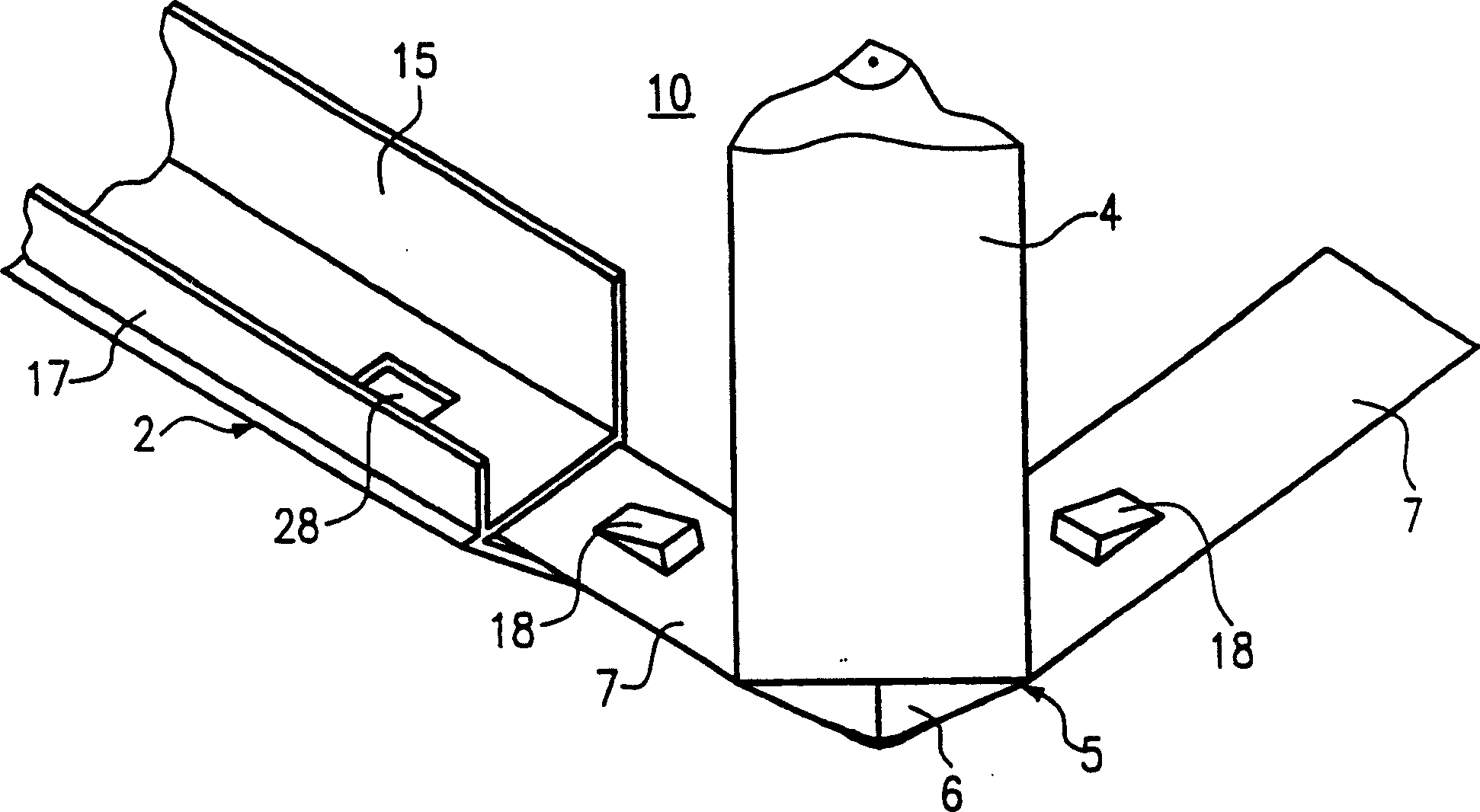

[0030] Figure 1 shows a corner connector 5 consisting of a corner piece 6 and two fixed extensions 7 at right angles to each other and lying in the same plane. In this embodiment, the corner connector 5 is used to form a rear left corner according to FIG. 2, wherein a transverse profile 2, a longitudinal profile 3 and a vertical profile 4 are arranged along the X, Y and Z coordinate axes . The two fixing extensions 7 of the corner connector 5 have a triangular cross-section with engaging elements 18 for securely fixing the installable transverse profiles 2 and longitudinal profiles 3 . The transverse profile 2 and the longitudinal profile 3 are cut to length from triangular hollow profiles whose structure exactly matches that of the fixed extension 7 and can be fitted or engaged on the fixed extension 7 with limited play.

[0031] Firmly and substantially non-detachable fixation of the installed transverse profile 2 and longitudinal profile 3 is achieved by means of grooves 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com