Reference voltage generating circuit and generating method, display drive circuit and display

A reference voltage and generating circuit technology, applied in the direction of adjusting electric variables, static indicators, cathode ray tube indicators, etc., can solve the problem that the charge and discharge time cannot be fully guaranteed, the current of the ladder resistance increases, and the resistance ratio of the ladder resistance Small problems, to achieve the effect of shortening charging time, reducing current consumption, and reducing charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The best mode of the present invention will be described in detail below using the drawings. In addition, the embodiments described below do not unduly limit the content of the present invention described in the claims. In addition, not all the configurations described below are essential configuration requirements of the present invention.

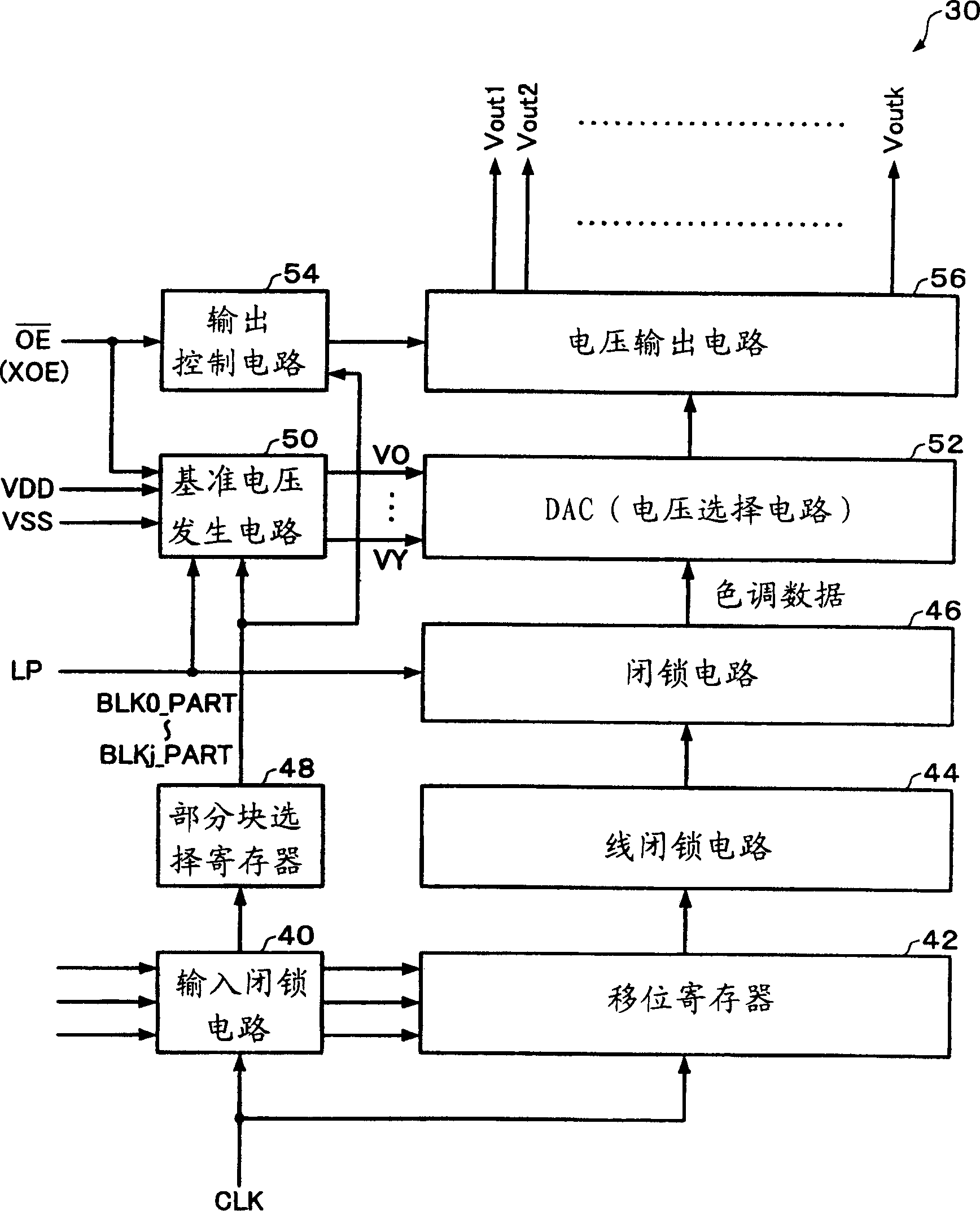

[0063] The reference voltage generation circuit in this embodiment can be used as a gamma correction circuit. This gamma correction circuit is included in a display drive circuit. The display driving circuit can be used for driving an electro-optical device whose optical properties are changed by an applied voltage, such as a liquid crystal device.

[0064] Although a case where the reference voltage generating circuit of this embodiment is used in a liquid crystal device will be described below, it is not limited thereto and can be applied to other display devices.

[0065] 1. Display device

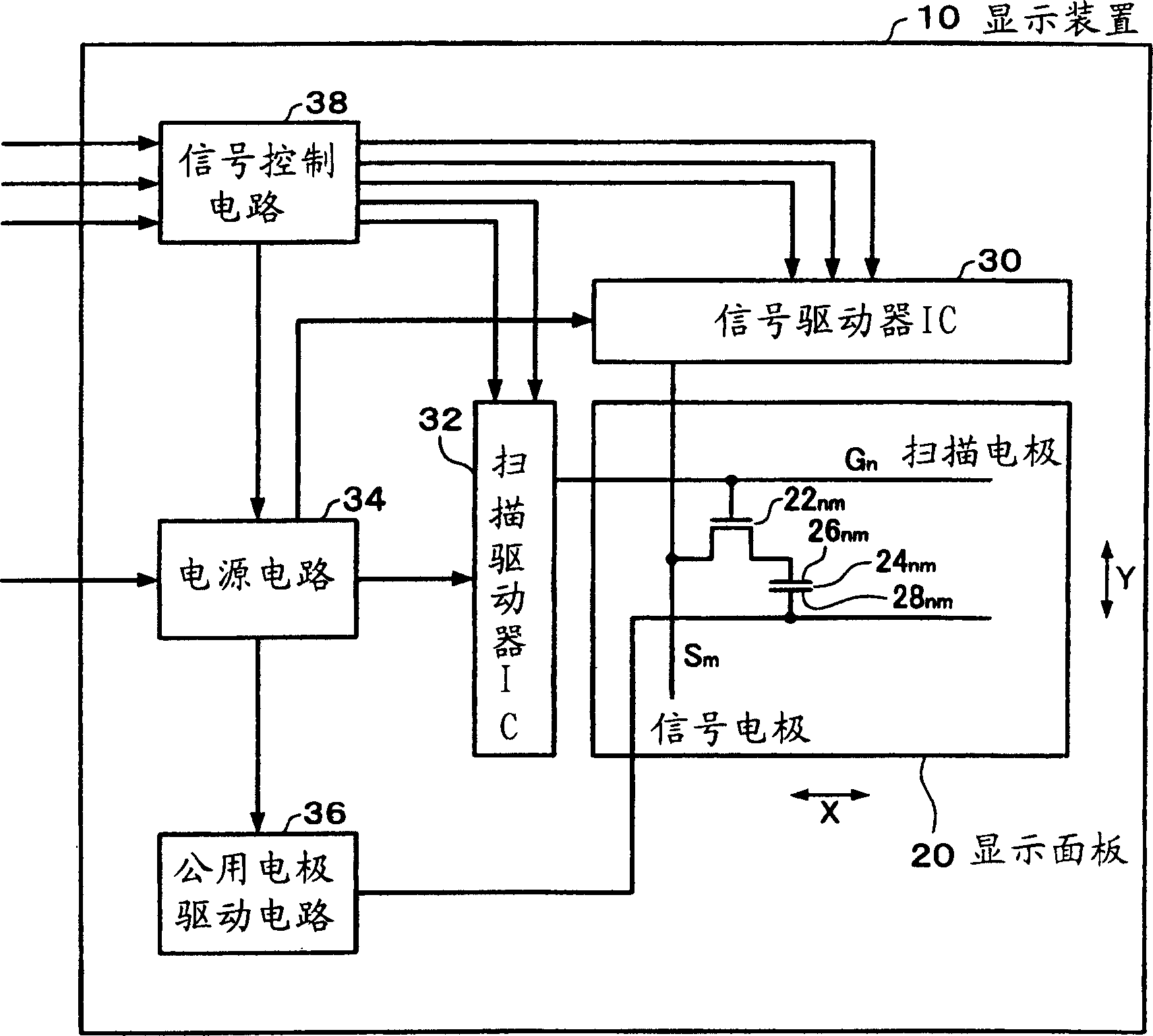

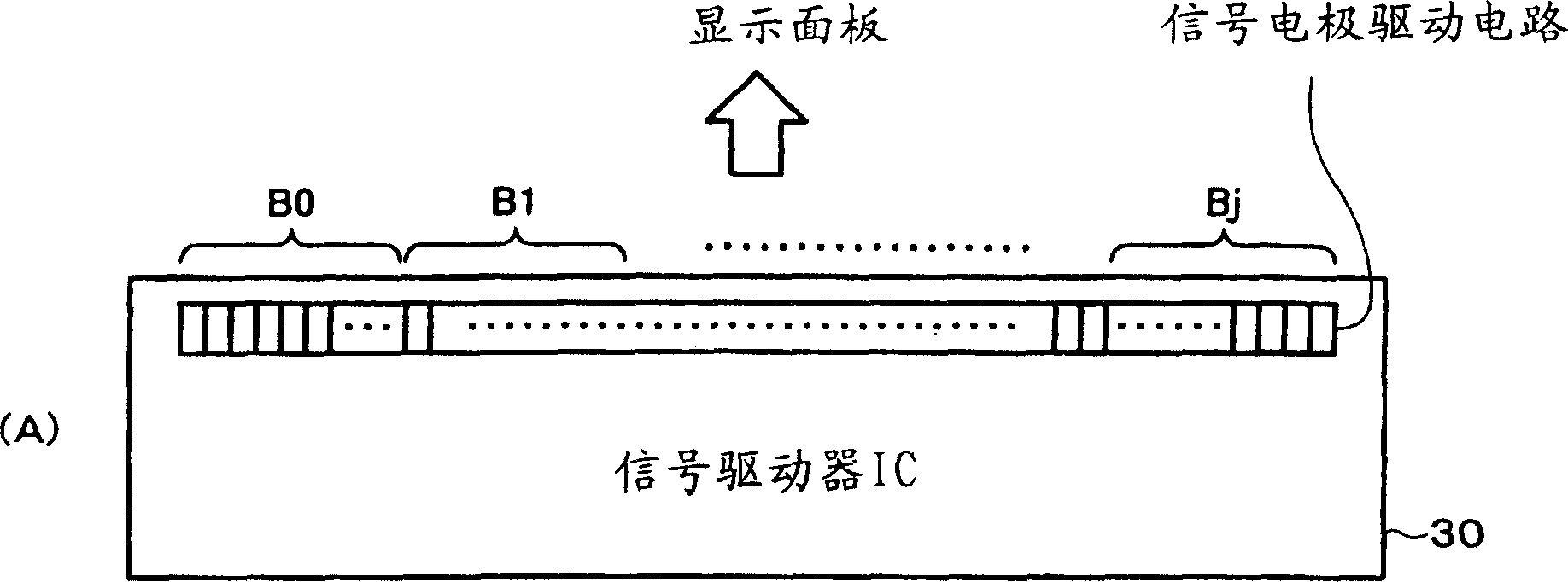

[0066] figure 1 An outline of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com