Multilayer film structure electrochromic displayer

An electrochromic, multi-layer film technology, applied in instruments, nonlinear optics, optics, etc., can solve the problem of single variable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

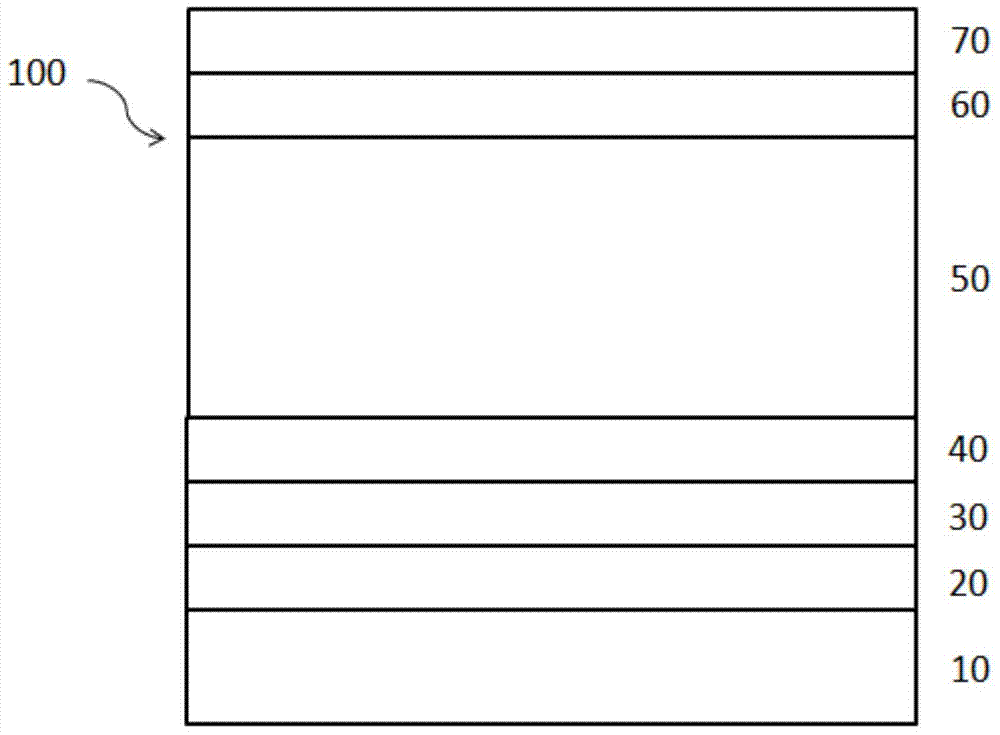

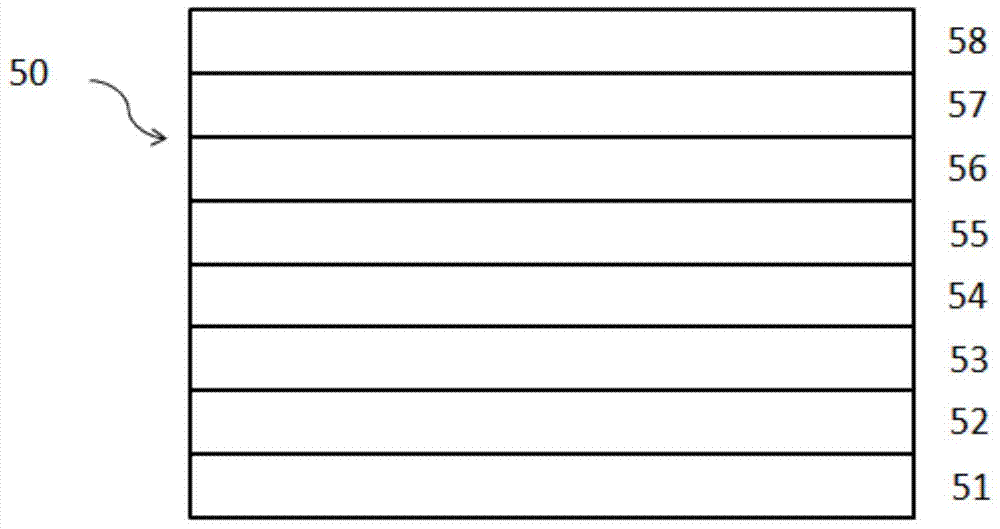

[0020] A multi-layer film structure electrochromic display 100, such as figure 1 . Using any material as the substrate 10, the bottom electrode layer 20, the ion storage layer 30, the electrolyte layer 40, the one-dimensional photonic crystal color-changing layer 50, the top electrode layer 60 and the protective layer 70 are sequentially sputtered by magnetron sputtering.

[0021] Wherein the substrate 10 can be any flexible or rigid substrate, which plays a role in supporting the entire display; the bottom electrode layer 20 and the top electrode layer 60 can be the same or different, and it is made of transparent metal oxides such as tin-doped indium oxide, fluorine-doped mixed tin oxide, aluminum-doped zinc oxide; the ion storage layer 30 can be any electrochromic material, such as tungsten oxide, nickel oxide, titanium oxide, molybdenum oxide, vanadium pentoxide, or two of them or a variety of mixtures; the electrolyte layer 40 is an electronically insulating and ion-cond...

specific Embodiment approach 2

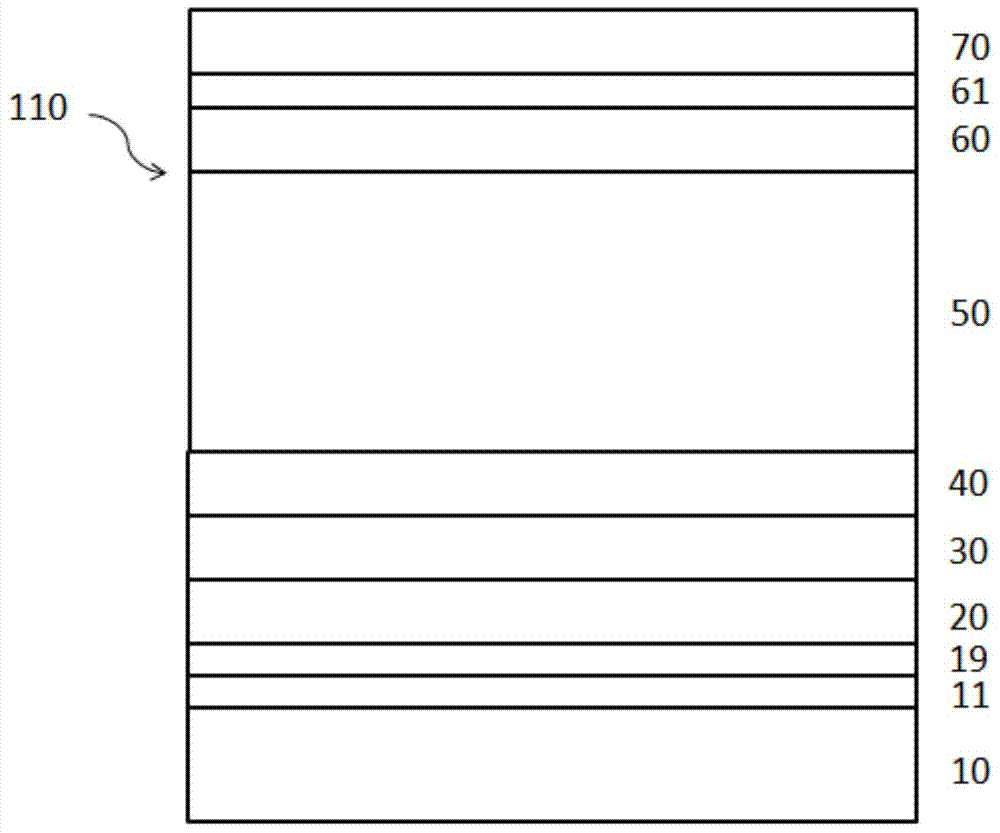

[0023] A multi-layer film structure electrochromic display 110, such as image 3 . Using any material as the substrate 10, use the magnetron sputtering method to sequentially sputter the ion barrier layer 11, the bottom metal electrode layer 19, the bottom electrode layer 20, the ion storage layer 30, the electrolyte layer 40, the one-dimensional photonic crystal color-changing layer 50, The top electrode layer 60 , the top metal electrode layer 61 and the protection layer 70 .

[0024] Wherein the substrate 10 rigid glass substrate plays the role of supporting the whole display; the ion blocking layer 11 is generally made of silicon dioxide to prevent sodium ions in the glass from entering the device; the bottom metal electrode layer 19 and the top metal electrode layer 61 are made of metal The bottom electrode layer 20 and the top electrode layer 60 can be the same or different, and they are made of transparent metal oxides such as tin-doped indium oxide, fluorine-doped tin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com