Preparation method of polymer photonic crystal with adjustable photonic band gap and patterned color display

A photonic band gap and photonic crystal technology, which is applied in the field of polymer photonic crystal preparation, can solve the problems of sample lattice defects, complex process requirements, low toughness and volume expansion ratio, etc., and achieve low control voltage, clear color boundary, The effect of the rapid preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

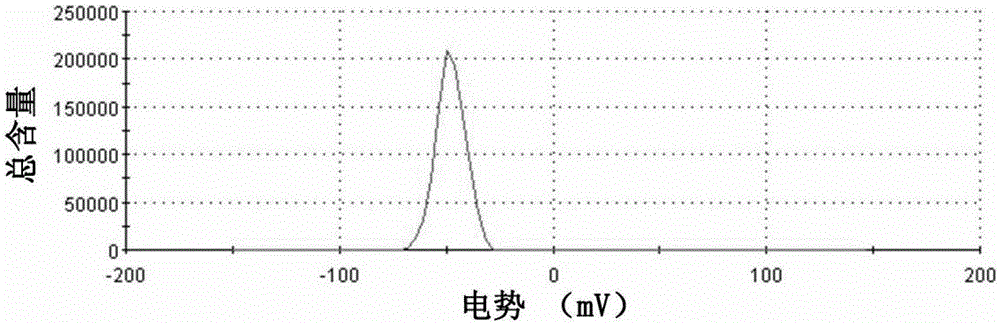

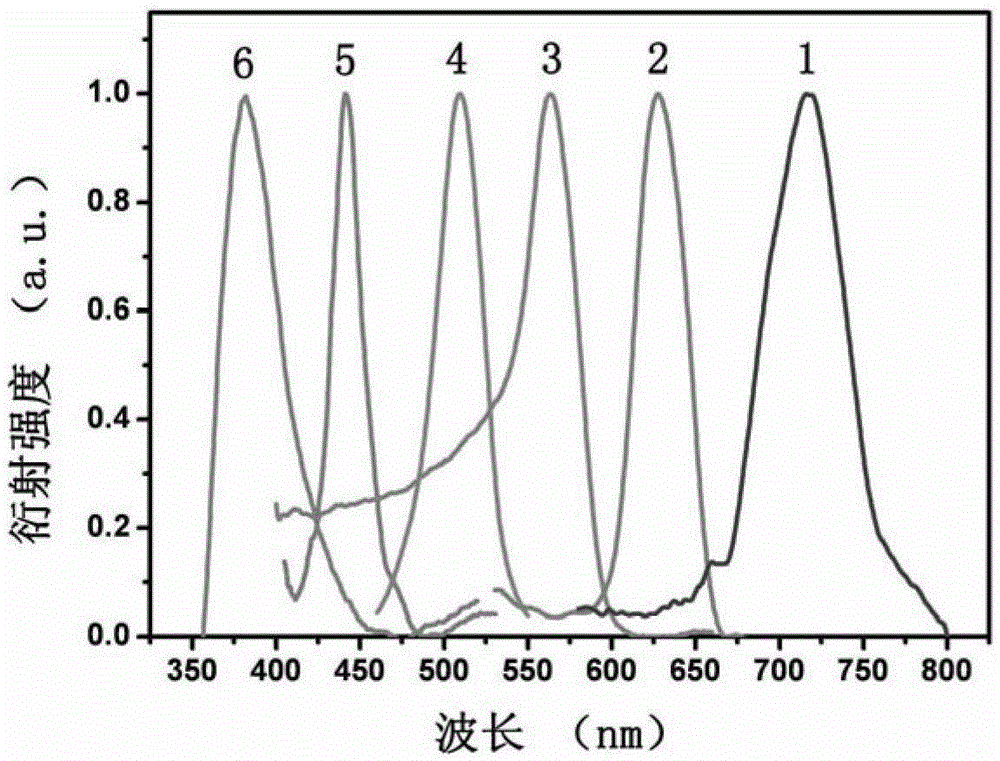

[0026] (1) Put N,N dimethylacrylamide (2mL), styrene (5mL), emulsifier (SDS, 0.05g) and deionized water (150mL) into a reaction vessel by emulsion polymerization, and put The reactor was placed in a water bath, first mechanically stirred (400r / min) at room temperature and nitrogen was blown for 30 minutes to make the micelles in the system evenly distributed. Then the temperature was raised to 70°C, and an initiator (KPS, 0.45 g) was added to react for 8 hours to obtain a monodisperse hydrogel polymer microsphere emulsion with a particle size of 180 nm. The reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomers and initiators, and a potential test was performed on it, and the result was that the surface had a surface potential of -45.7mV.

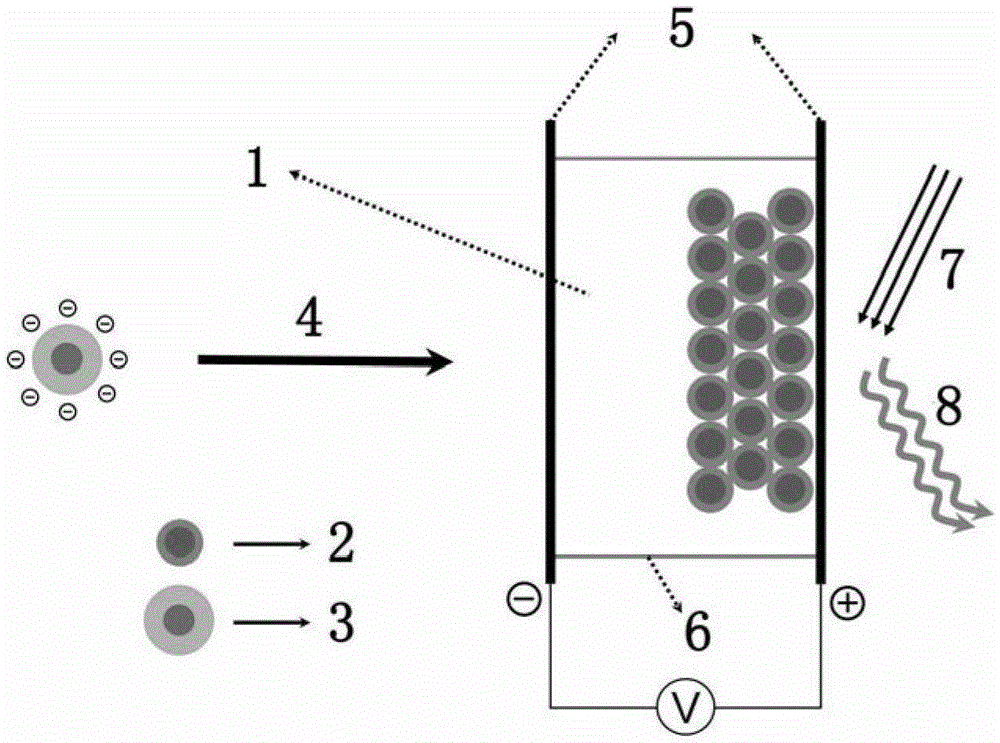

[0027] (2) Place the hydrogel polymer microsphere emulsion with uniform size and high negative potential obtained in step (1) (the solid content of the emulsion is 6%) in a glass pool with ITO ...

Embodiment 2

[0030] (1) Through emulsion polymerization, put N isopropylacrylamide (5mL), α-methylstyrene (5mL), emulsifier (SDBS, 0.05g) and deionized water (300mL) into a reaction vessel , put the reactor in a water bath, first mechanically stir (400r / min) at room temperature and blow nitrogen for 30 minutes, so that the micelles in the system are evenly distributed. The temperature was raised to 70°C, and then an initiator (V50, 0.45g) was added to react for 8 hours. Obtain a particle diameter of 150nm, size monodisperse hydrogel polymer microsphere emulsion, the reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomer and initiator, and it was subjected to potential test, the result was surface band There is a surface potential of +45.0mV.

[0031] (2) Put the hydrogel polymer microsphere emulsion with uniform size and high positive potential obtained in step (1) (the solid content of the emulsion is 5%) in a glass pool with ITO inner walls ...

Embodiment 3

[0034] (1) Put glycidyl methacrylate (2mL), divinylbenzene (5mL) and deionized water (150mL) into a reaction vessel (SDS, 0.01g) by means of emulsion polymerization. Place the device in a water bath, first mechanically stir (400r / min) at room temperature and blow nitrogen for 30 minutes, so that the micelles in the system are evenly distributed. Afterwards, the temperature was raised to 70° C., and then an initiator (SPS, 0.40 g) was added to react for 8 hours. The hydrogel polymer microspheres with a particle size of 200nm and monodisperse size were obtained, and the reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomers and initiators, and a potential test was carried out on it. The result was that the surface had Surface potential of -40.0 mV.

[0035] (2) The hydrogel polymer microspheres with uniform size and high negative potential obtained in step (1) (the solid content of the emulsion is 9%) were placed in a glass pool wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com