Settling centrifuger with internal rotor

A settling centrifuge and rotor technology, which is applied to centrifuges with rotating drums, centrifuges, and centrifuges to separate sediments by centrifugal force, which can solve the problem of unsatisfactory separation of fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

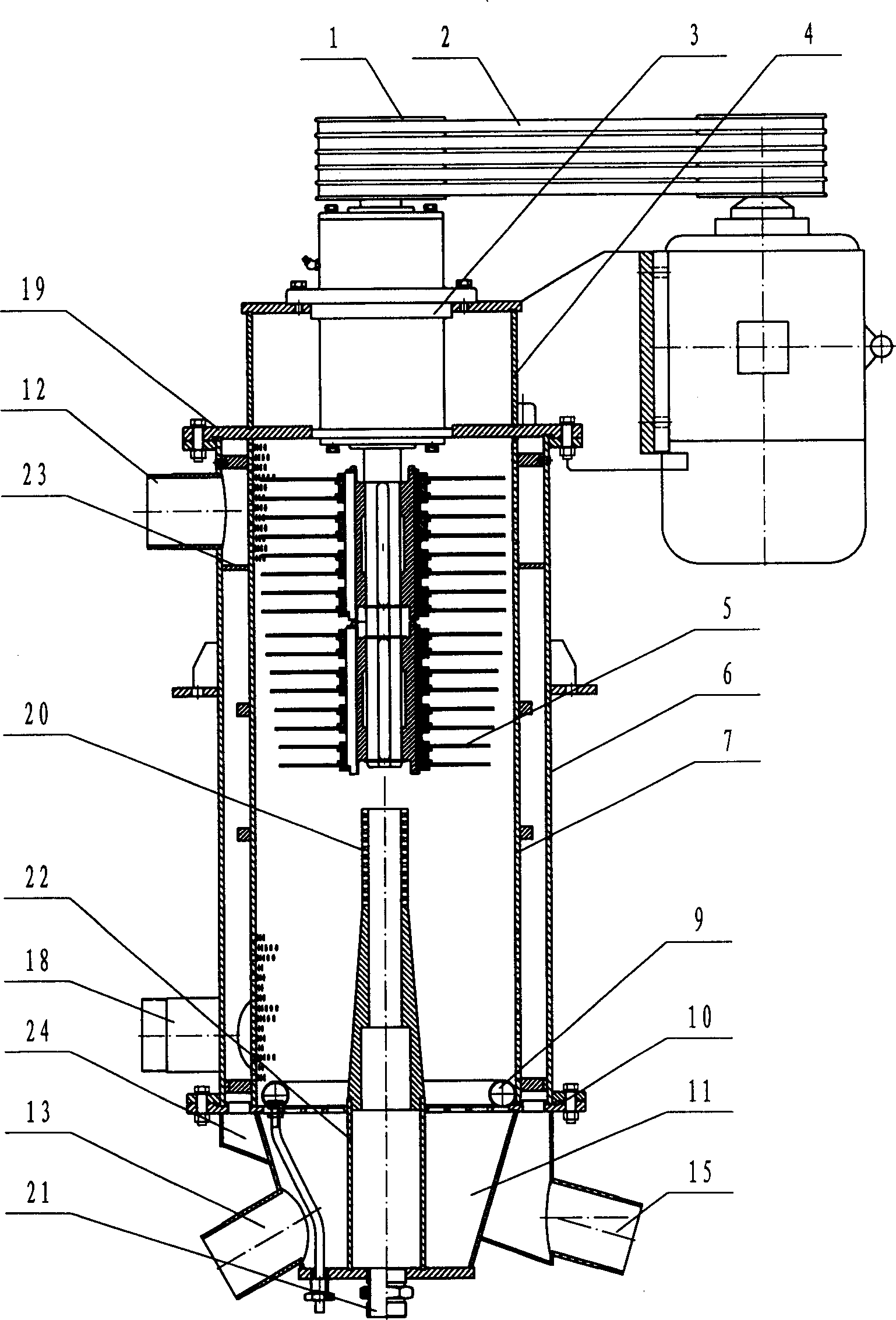

[0081] Because the rotor is light, the centrifuge of the present invention has separate, horizontal, and inclined-horizontal structures.

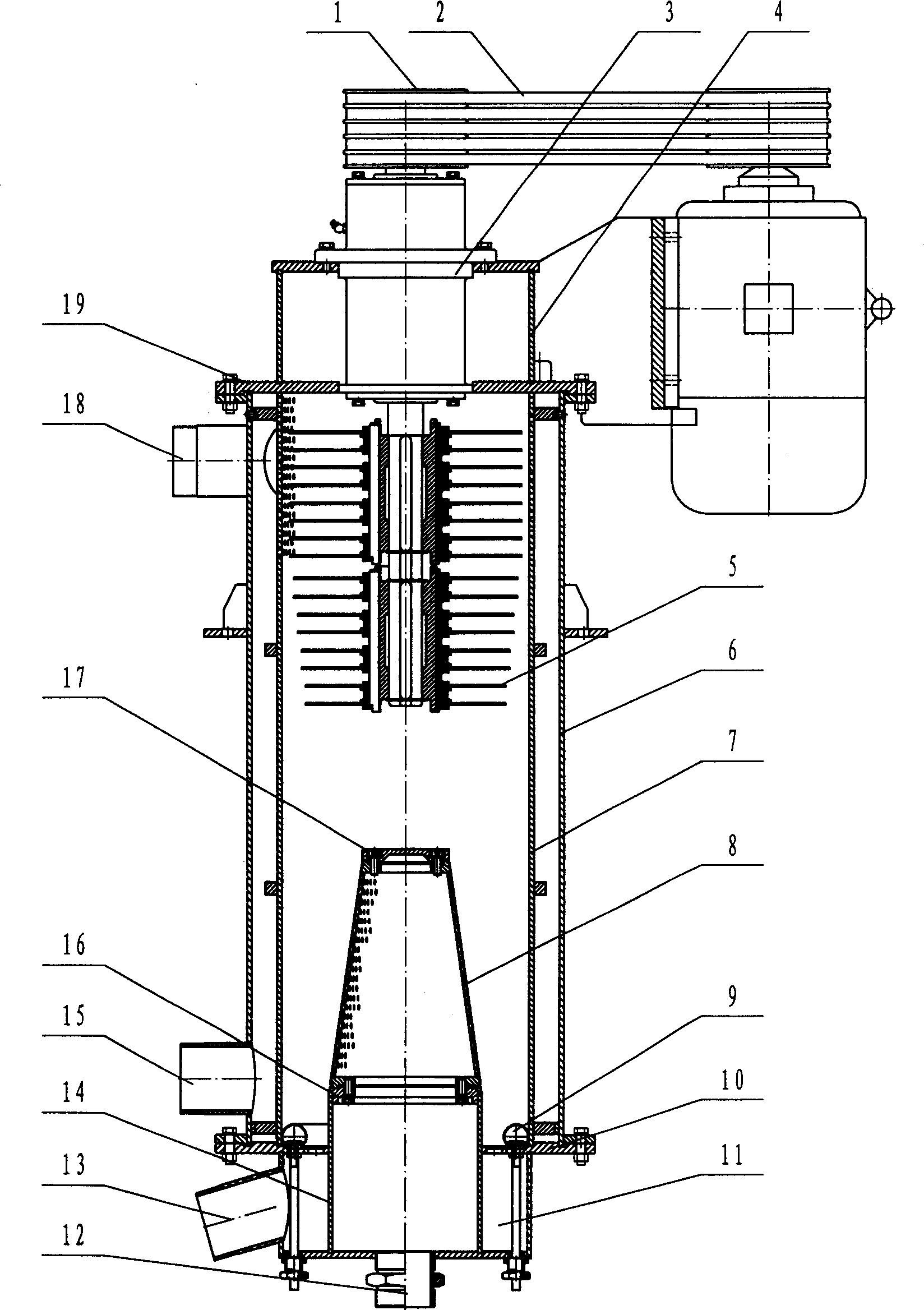

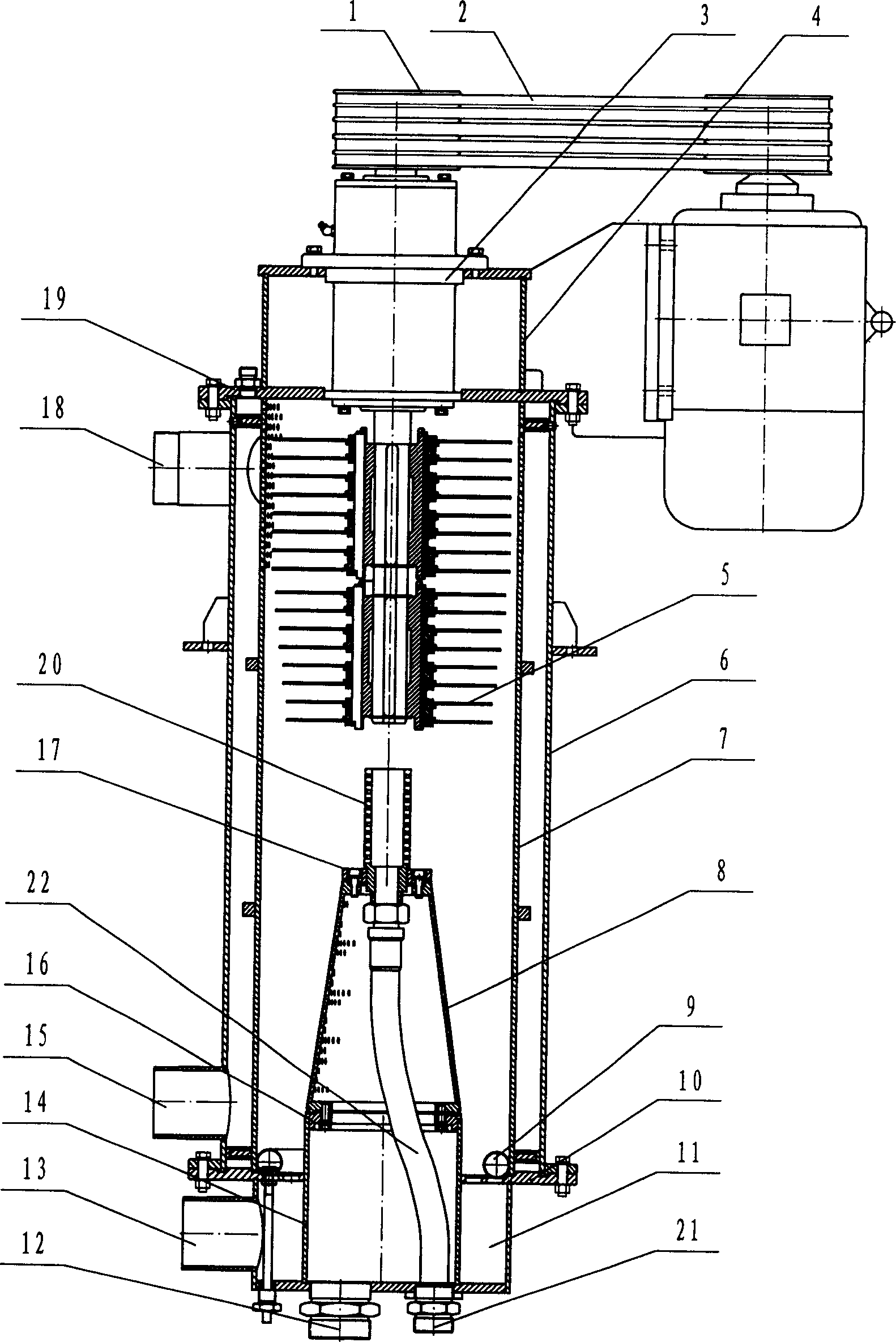

[0082] figure 1 As shown, it is a vertical upward-feeding pulp two-phase separation internal rotor settling centrifuge designed according to the technical solution of the present invention. The centrifuge is composed of a transmission device 3, a pin wheel 5 rotor, a transmission positioning assembly 4, a centrifugal cavity assembly 7, a shell assembly 6, a slurry filter 8, an aerator 9 and a discharge assembly.

[0083] Needle wheel 5 is that U-shaped needle seedlings are radially evenly densely arranged and hung on the ring sheet, and the ring sheet of the needle seedlings plus the spacer ring are layered and stacked and combined on the wheel hub through the key plate and the elastic retaining ring. There are two pin wheels 5 connected in series on the power transmission shaft with a certain interval. The overall profile of the pin whee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap