Polysiloxane intermediate, its preparing process and application

A polysiloxane and intermediate technology, applied in the field of polysiloxane intermediates and its preparation and application, can solve the problems of large limitations, physical state and physical properties, etc., and achieve the effect of enriching content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

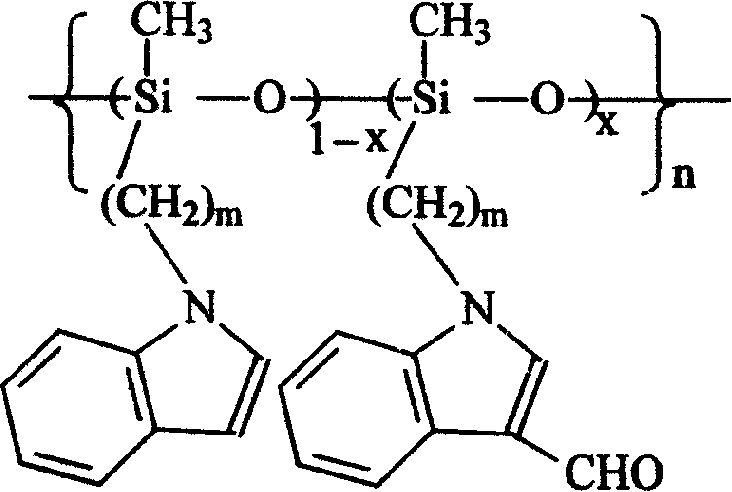

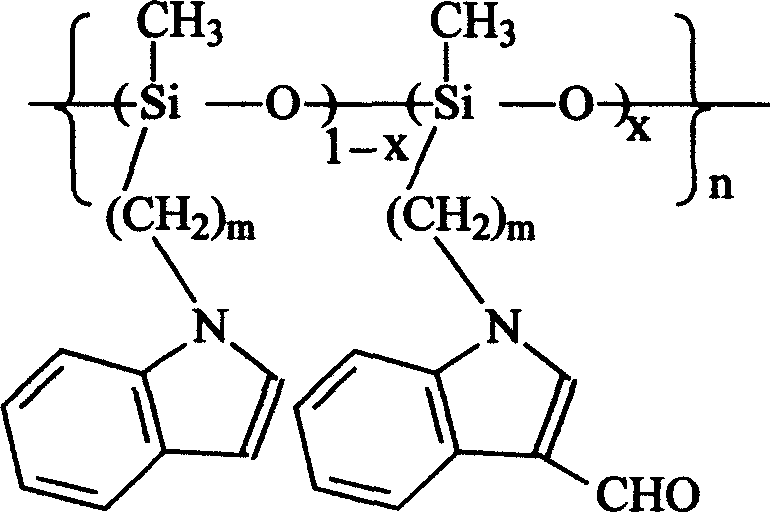

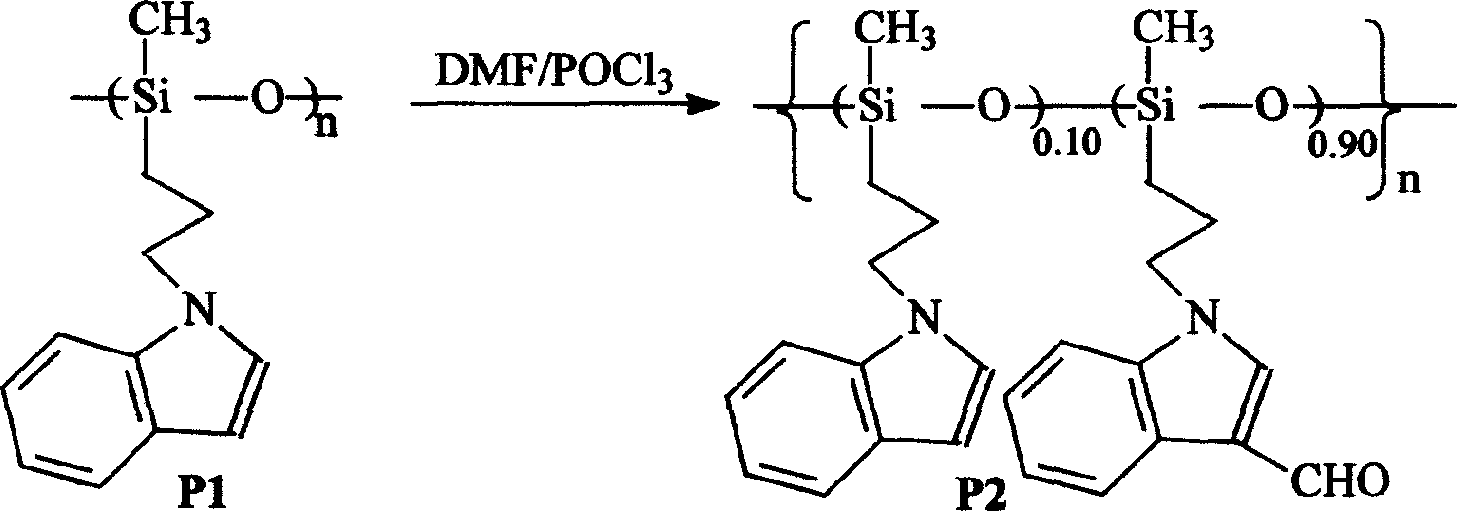

[0015] When the coefficient x is 0.90 and m is 3, the synthesis route is as follows:

[0016]

[0017] The synthesis method is: in a Schlenk tube equipped with a stirring magnet, add hydrogen-containing silicone oil, N-allyl indole, a little dichlorodicyclopentadiene platinum catalyst, anhydrous toluene, under the condition of argon protection The reaction was stirred at 60°C for 48 hours, cooled to room temperature, and a large amount of solvent was distilled off under reduced pressure. Then add an appropriate amount of methanol, put it in the refrigerator for two hours, pour out the supernatant, dissolve the precipitate in a small amount of chloroform, and then reprecipitate with methanol, and do this several times to obtain a light green viscous solid P1, which is vacuum-dried at 40°C . Wherein the molar ratio of hydrogen-containing silicone oil to N-allylindole is 1:2.

[0018] Under the protection of an argon atmosphere, the molar ratio of P1:phosphorus oxychloride i...

Embodiment 2

[0025] When the coefficient x is 0.20 and m is 11, the synthesis route is as follows:

[0026]

[0027] The synthesis method is as follows: in a Schlenk tube equipped with a stirring magnet, add hydrogen-containing silicone oil, N-undecenyl indole, a little dichlorodicyclopentadiene platinum catalyst, anhydrous toluene, The reaction was stirred at 60°C for 48 hours under the condition, cooled to room temperature, and a large amount of solvent was distilled off under reduced pressure. Then add an appropriate amount of methanol, put it in the refrigerator for two hours, pour out the supernatant, dissolve the precipitate in a small amount of chloroform, and then re-precipitate with methanol, and do this several times to obtain a light green viscous liquid P7, which is vacuum-dried at 40°C . Wherein the molar ratio of hydrogen-containing silicone oil to N-undecenylindole is 1:2.

[0028] Under the protection of argon atmosphere, the molar ratio of P7:phosphorus oxychloride is...

Embodiment 3

[0035] When the coefficient x is 0.05 and m is 3, the synthesis route is as follows:

[0036]

[0037] The synthesis method is as follows: see Example 1 for the synthesis of P1.

[0038] Under the protection of an argon atmosphere, the molar ratio of P1:phosphorus oxychloride is 1:0.07, and phosphorus oxychloride is added to the N,N-dimethylformamide solution of P1 (concentration is 6~15wt%) ), react at 0°C for 50 minutes; then react at 50°C for 20 minutes, separate and purify to obtain the desired polysiloxane intermediate P13.

[0039] Examples of synthetic applications are as follows (synthesis of polysiloxane polymers with second-order nonlinear optical chromophores):

[0040] The synthesis methods are generally similar, and the usual synthesis steps are as follows:

[0041] Under the protection of argon atmosphere, dissolve P13 (2.5 mmol), cyanoacetylated chromophore (0.2 mmol) and hexahydropyridine (three drops) in 1.5 mL of freshly distilled N,N-dimethylformaldehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com