Microwave oven with air-exhausting function

A microwave oven and functional technology, applied in the microwave oven field, can solve the problems of complicated assembly, loud microwave oven noise, insufficient heating, etc., and achieve the effect of reducing noise and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

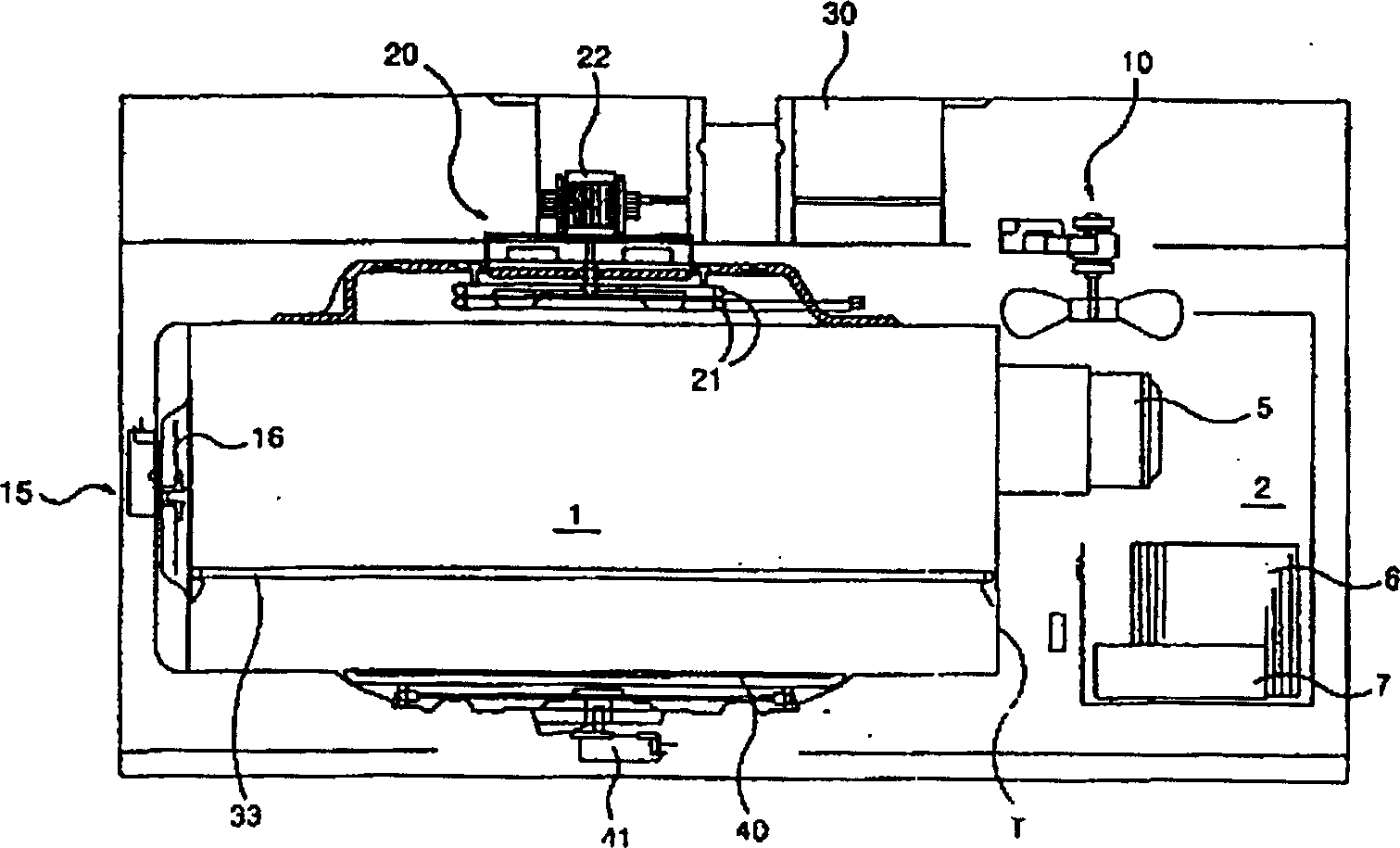

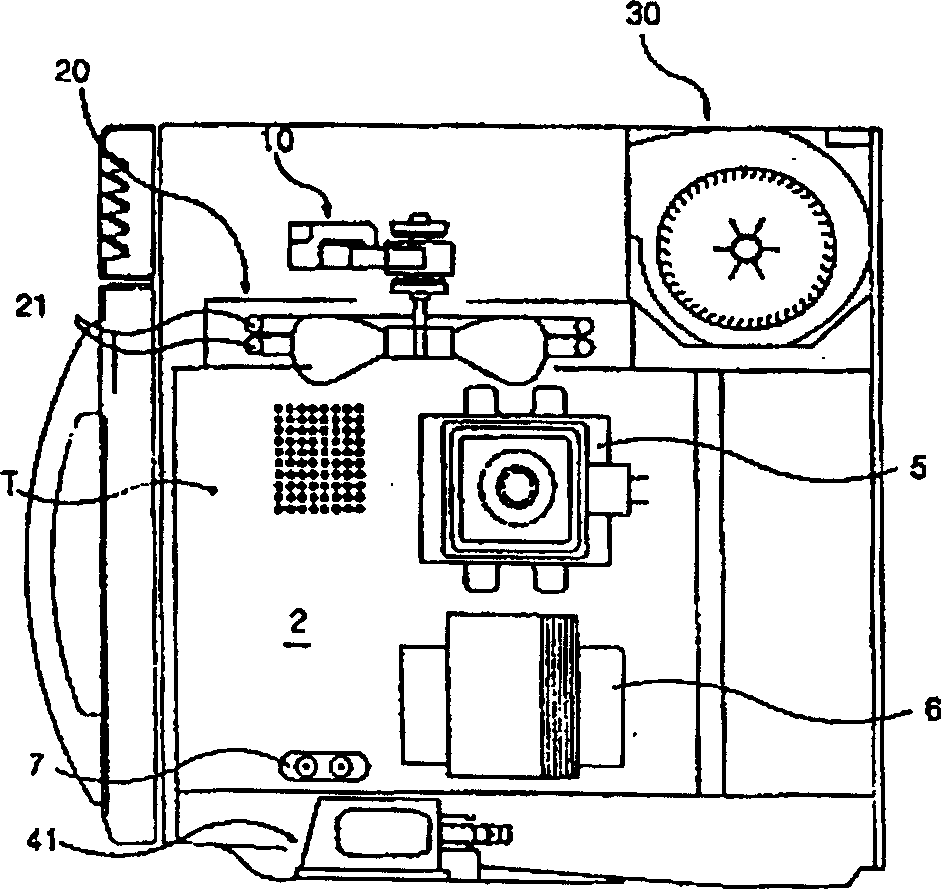

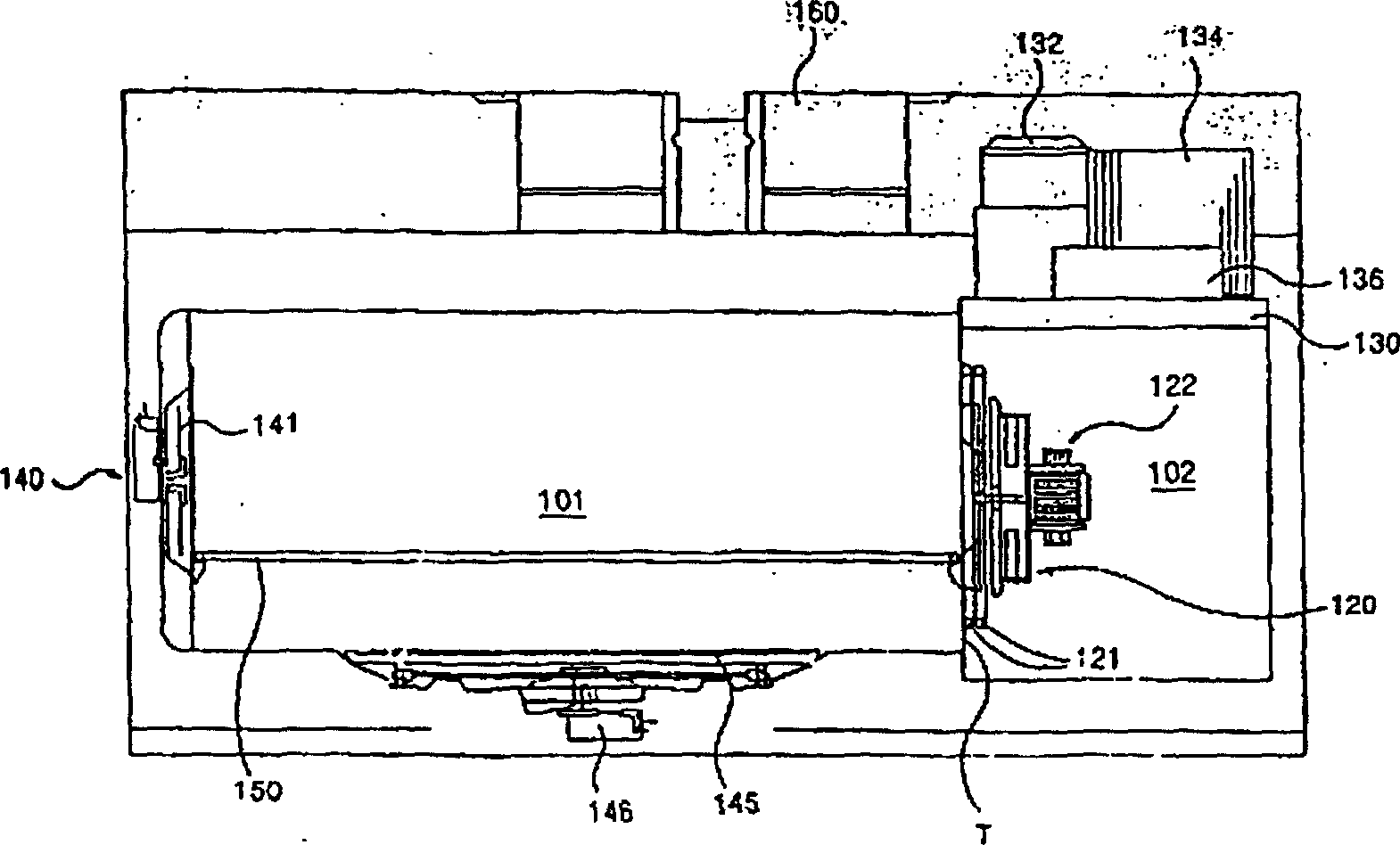

[0017] refer to image 3 with Figure 4 As shown, the oven chamber 101 for cooking food and the electric field chamber 102 above which electric field devices are installed are formed in the microwave oven with exhaust function of the present invention.

[0018] The electric field chamber 102 is equipped with a hot air convection heater group 120 by the side T of the furnace cavity 101, and the hot air convection heater group 120 is the same as the prior art. The generated hot air is sent into the oven cavity 101 to form a hot air convection fan group 122 . An installation surface 130 is arranged at the same height as the top surface of the furnace cavity 101 above the hot air convection heater group 120. The installation surface 130 is plate-shaped and is used to install electric field devices such as a magnetron 132, a high-voltage transformer 134, and a high-voltage capacitor 136 as shown in the figure. . One side of the furnace chamber 101 is provided with a stirring fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com