Hydrocarbon adsorption dearylating process

A dearomatization and adsorbent technology, which is applied in the direction of adsorption purification/separation, refined hydrocarbon oil, petroleum industry, etc., can solve the problems that there is no separation of aromatic impurities adsorption cycle method, and achieve the effect of energy consumption optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

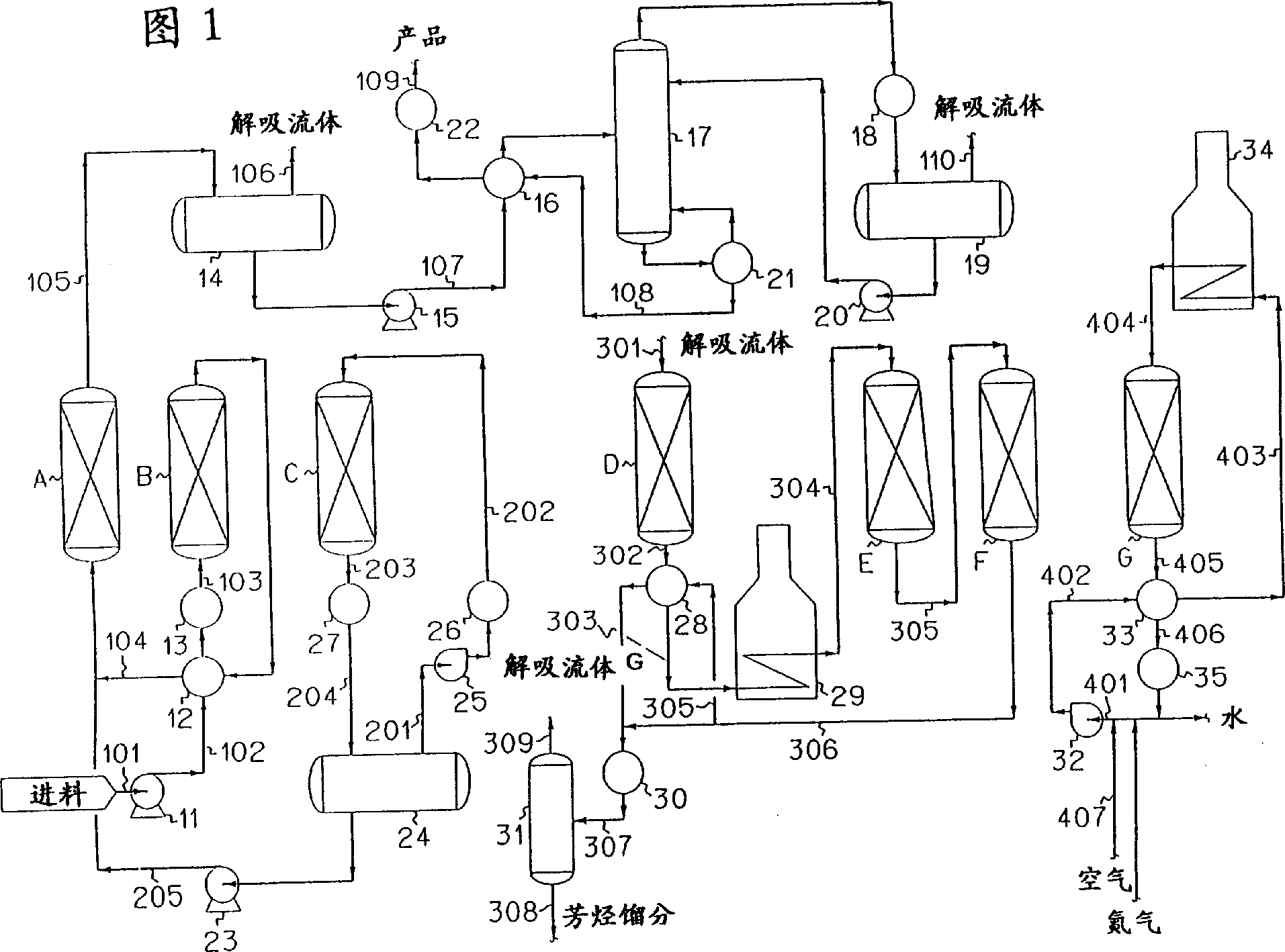

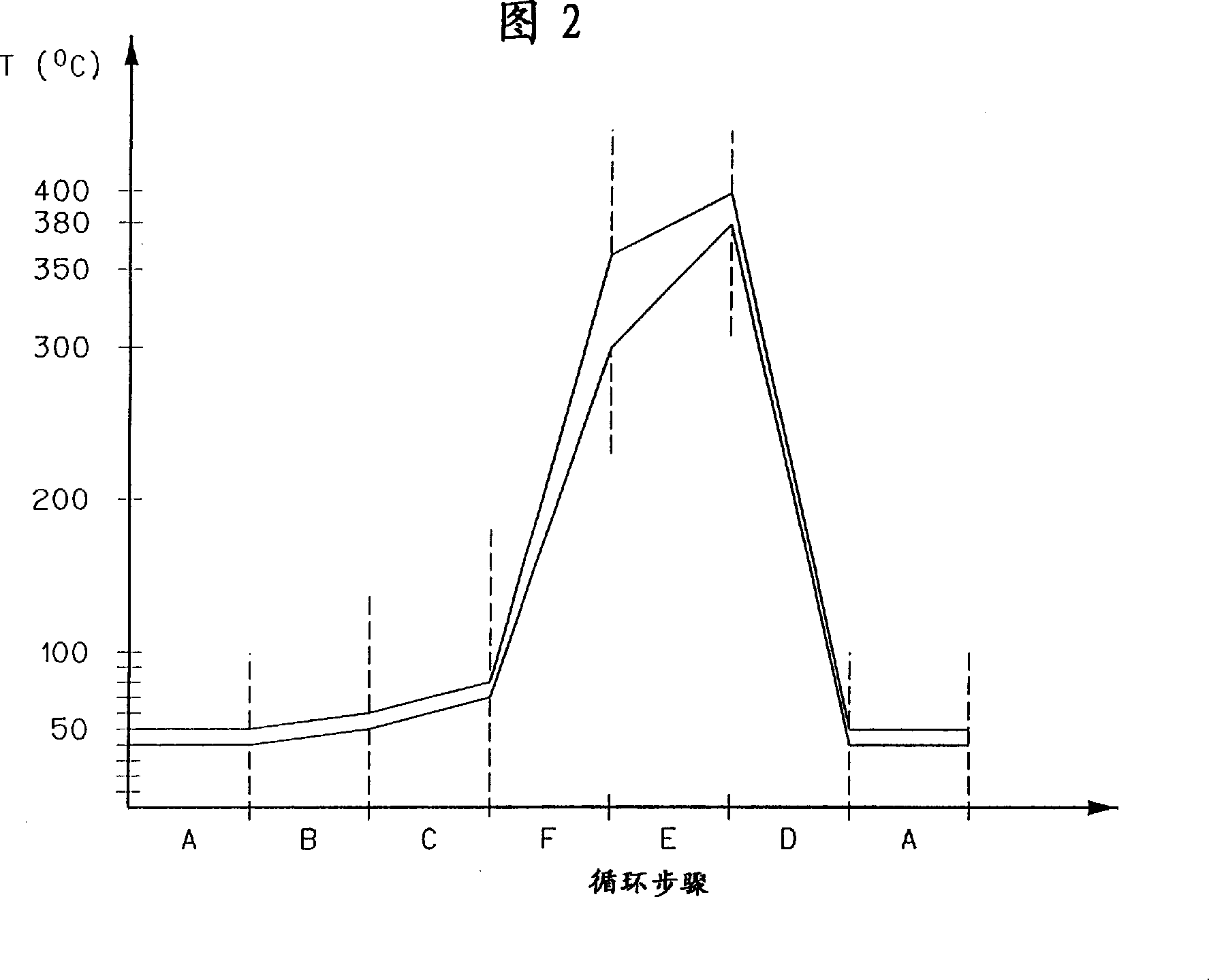

Method used

Image

Examples

Embodiment Construction

[0047] The following terms used in the description and claims of the present method are defined as follows: Desorption fluid

[0048] Refers to the fluid used in the cooling, draining / rinsing and desorption steps in the process. Hydrocarbon stream or feed

[0049] Refers to the hydrocarbon stream mixed with aromatics, which is to be treated by dearomatization. cycle hydrocarbon

[0050] Refers to the hydrocarbon feed recovered in the blowdown / flush step. gasified hydrocarbon

[0051] Refers to the effluent from the adsorber mixed with dissolved desorption fluid. hydrocarbon products

[0052] Refers to the effluent hydrocarbons from the degassed stripper (17). Aromatic fraction

[0053] Refers to a hydrocarbon stream mainly containing aromatic compounds, which is sent to the fuel pool. Nitrogen

[0054] is the inert gas used in the adsorbent regeneration step. Another use of this inert gas is to replace the desorption fluid as a desorbent in a closed loop. Adsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com