Method for preparing lignocellulose for road

A wood fiber and road-use technology, applied in the field of road wood fiber preparation, can solve the problems of inconvenient addition of asphalt mixture, no public reports in literature, high sealing requirements, etc., and achieve low production cost, high oil absorption value, and preparation process conditions moderating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

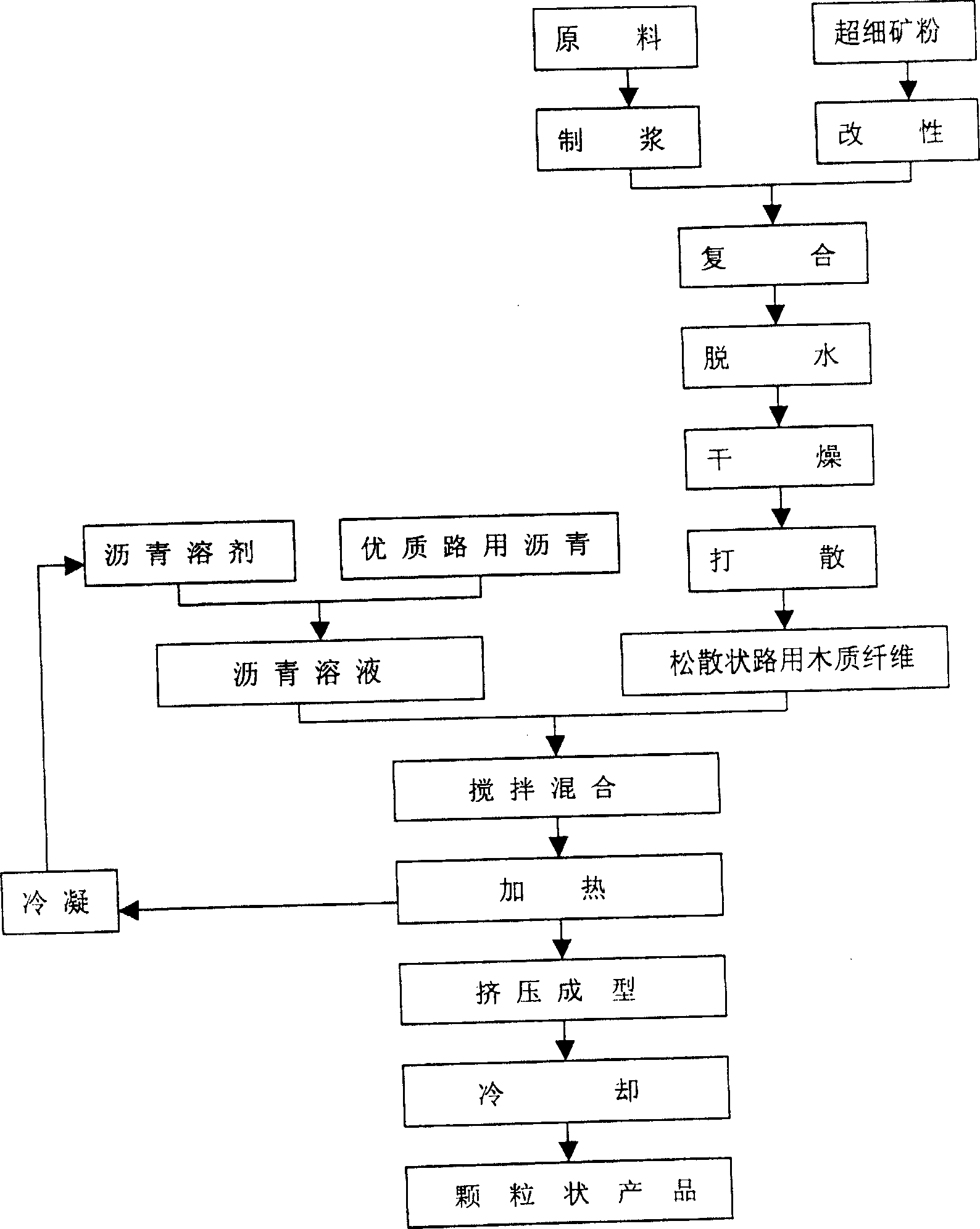

Method used

Image

Examples

example 1

[0020] Take 0.4Kg of coated kaolin and add it to a high-speed heating mixer, set the temperature at 30°C, start the machine for 5 minutes, add titanate coupling agent 311-7 into the mixer, the titanate coupling agent The addition amount is 8g, the machine is turned off after 45 minutes of modification, the coated kaolin after modification is taken out, and the activation index is determined to be 82%.

[0021] Discarded newsprint is selected as the fiber raw material, the cellulose content is 93.4%, and the ash content is 6.6%. Take newsprint 3.6Kg and soak in water for 1 hour, make it into fiber pulp with beating equipment, the slurry concentration is 3%, pour the fiber slurry into composite equipment, add the coated kaolin after modification in the composite equipment, Start the emulsifier, control the rotor speed to 3000r / min, and after 10 minutes of timing, the compounding is completed. Pour the compounded slurry into the filter bag for filtration. After filtering, the fib...

example 2

[0024] Take 0.57Kg of coated kaolin and add it to a high-speed heating mixer, set the temperature at 35°C, start the machine for 5 minutes, add titanate coupling agent 311-7 into the mixing tank, the titanate coupling agent The addition amount is 17g, the machine is turned off after 50 minutes of modification, the coated kaolin after modification is taken out, and the activation index is determined to be 87%.

[0025]Discarded newsprint is selected as the fiber raw material, the cellulose content is 93.4%, and the ash content is 6.6%. Take newsprint 3.43Kg and soak in water for 1 hour, make it into fiber slurry with beating equipment, the slurry concentration is 4%, pour the fiber slurry into composite equipment, add the coated kaolin after modification in the composite equipment, Start the emulsifier, control the rotor speed to 4000r / min, and after 15 minutes, the reaction is over. Pour the reacted slurry into the filter bag for filtration. After filtering, the fibers are ent...

example 3

[0028] Take 0.73Kg of coated kaolin and add it to a high-speed heating mixer, set the temperature at 40°C, start the machine for 5 minutes, add titanate coupling agent 311-7 into the mixing tank, the titanate coupling agent The addition amount is 29g, the machine is turned off after 60 minutes of modification, the coated kaolin after modification is taken out, and the activation index is determined to be 85%.

[0029] Discarded newsprint is selected as the fiber raw material, the cellulose content is 93.4%, and the ash content is 6.6%. Take newsprint 3.27Kg and soak in water for 1 hour, make it into fiber slurry with beating equipment, the slurry concentration is 5%, pour the fiber slurry into composite equipment, add the coated kaolin after modification in the composite equipment, Start the emulsifier, control the rotor speed to 5000r / min, and after 20 minutes of timing, the reaction is over. Pour the reacted slurry into the filter bag for filtration. After filtering, the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com