Inserting needle contact part with spring for heat inserting and pull-out

A pin contact and strip spring technology, applied in the field of hot-swappable spring pin contacts, can solve problems such as contact performance limitations, connection failures, accidents, etc., achieve stable dynamic contact resistance, facilitate management and production, The effect of withstanding large current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

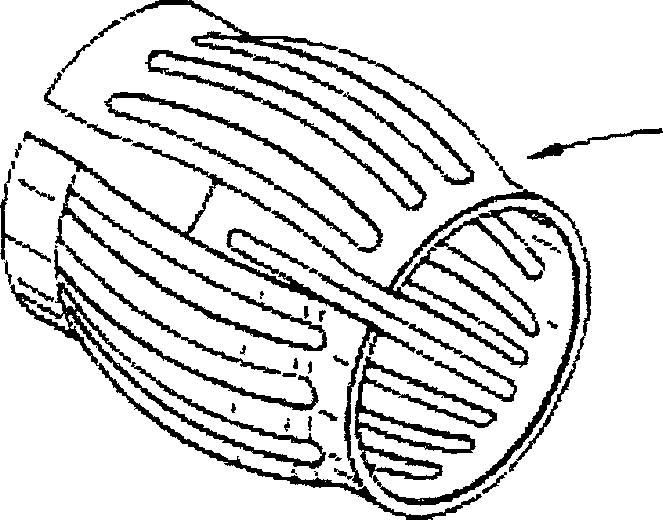

[0035] figure 1Shown is the "coil spring" figure shown in the accompanying drawing of the patent application publication number: CN1144020A "Connector for quick connection and disconnection". It can be seen from the figure that it is cylindrical, and the side wall is divided into A number of metal strips connected at both ends and perpendicular to the end surface are bent outwards into a bulging waist shape, showing a structure with small ends and a large middle.

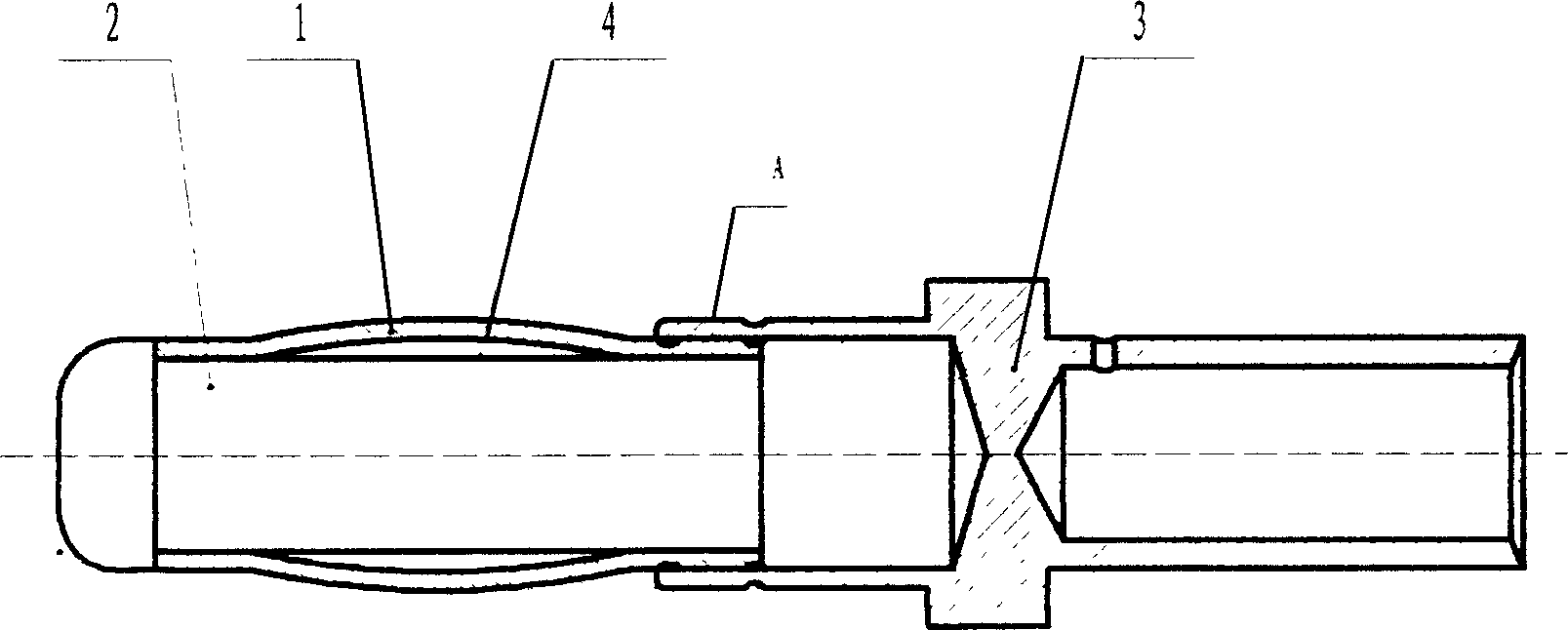

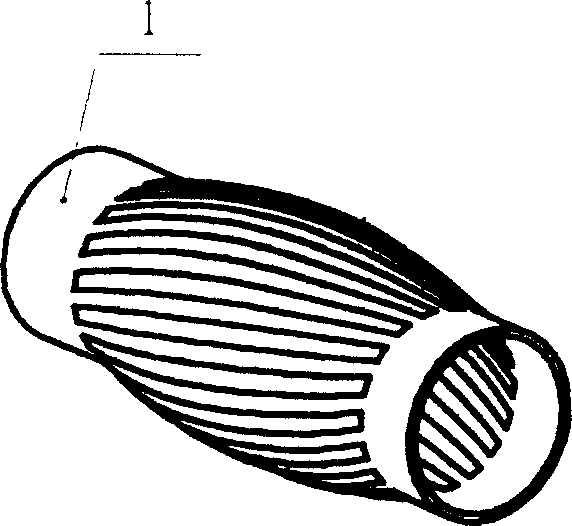

[0036] figure 2 The shown hot-swappable spring pin contact is composed of 4 sets of cylindrical rigid needle body 2 with a helical spring coil 1 in the middle annular groove, one end of which is embedded in the cylindrical blind hole on the end surface of the rear sleeve 3 , so that one end of the helical coil 1 is just clamped by the inner cylindrical surface of the blind hole of the rear sleeve 3 and the outer cylindrical surface of the rigid needle body 2, and the blind hole port of the rear sleeve 3 shrinks to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com