Textile construction and air sac and air belt made thereof

A surface and shape technology, applied in textiles and papermaking, textiles, fabrics, etc., can solve the problems of absolute air permeability fluctuation, impact on passengers, collapse, etc., and achieve the effect of considerable cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

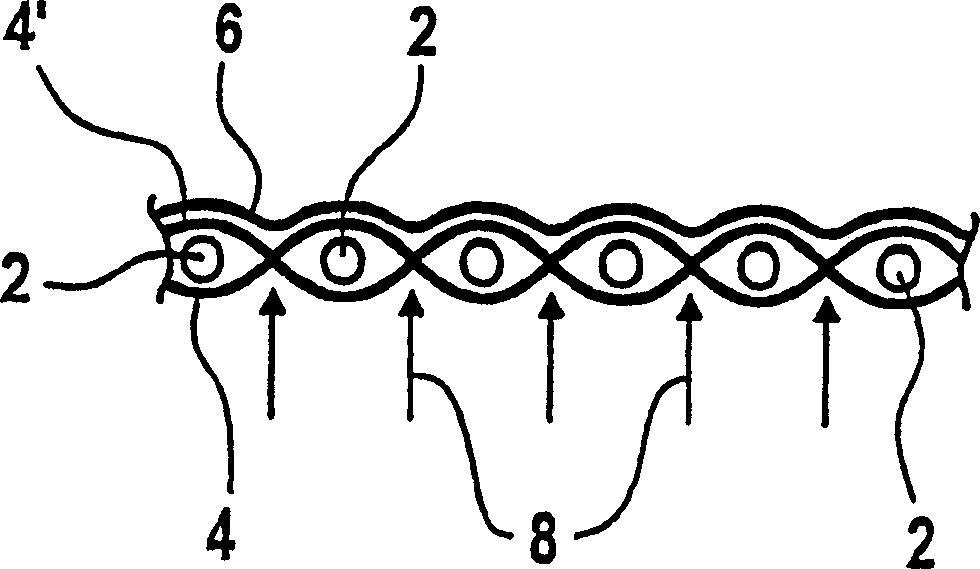

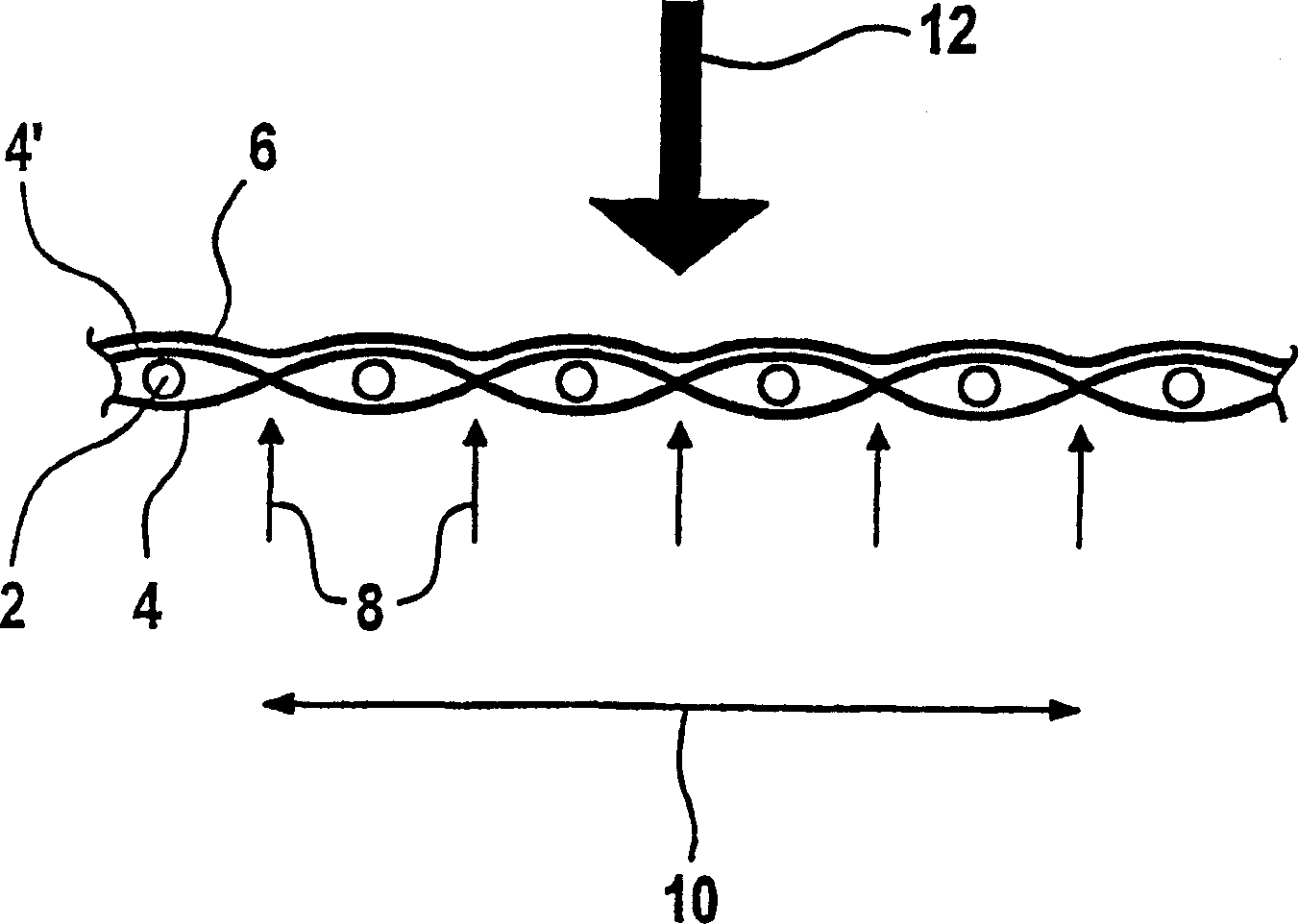

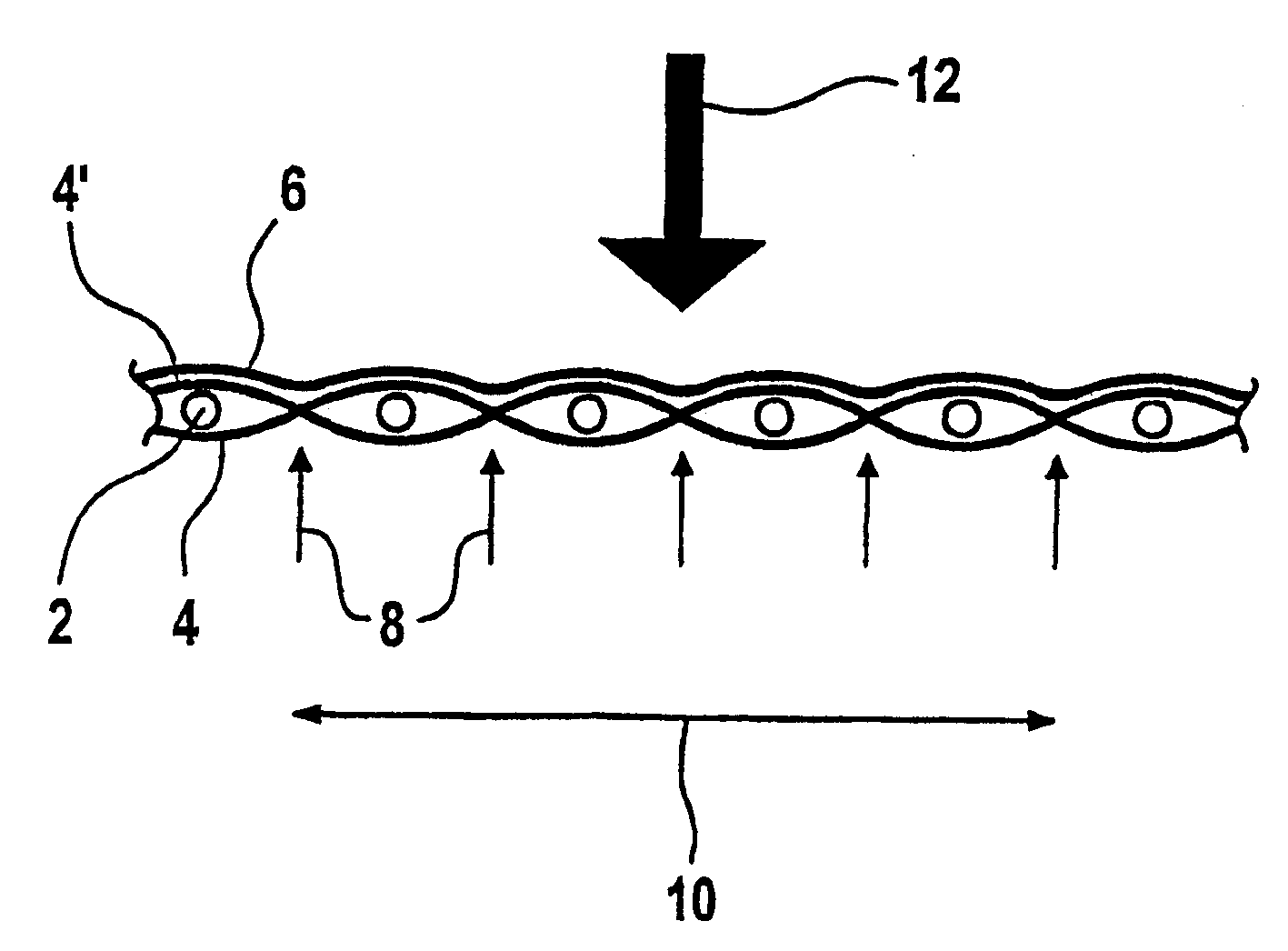

[0015] exist figure 1 A greatly simplified cross-section of an airbag fabric seen in the warp direction is shown in . Here, the warp 2 is shown as a small circle in the drawing plane, and simultaneously as a cross-sectional diagram of the warp 2, and the wefts 4 and 4' (shown in plain weave for simplicity here) are drawn from the left in the drawing plane. Stretch right and wrap warp 2 with open. (exist figure 1 Middle) A film 6 is applied on the upper surface of the fabric shown. The film is applied to the fabric, for example by thermal bonding or other usual bonding material. exist figure 1 The arrangement of the weft threads 4 and 4' and the warp threads 2 shown in , corresponds to the state of the airbag fabric, as it leaves the weaving machine and after gluing. Arrow 8 shows the amount of air desired and able to pass through the fabric or the air permeability of the fabric. That is to say, the air must reach between the threads or between the intersections of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com