Light-emission device and its manufacturing method

A technology of light emitters and emitters, which is applied in semiconductor/solid-state device manufacturing, instruments, light sources, etc., and can solve problems such as deterioration of screen clarity and display dysfunction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be described in terms of preferred embodiments, which are not intended to limit the scope of the invention but to illustrate the invention. All features and combinations thereof described in the embodiments are not necessarily essential to the invention.

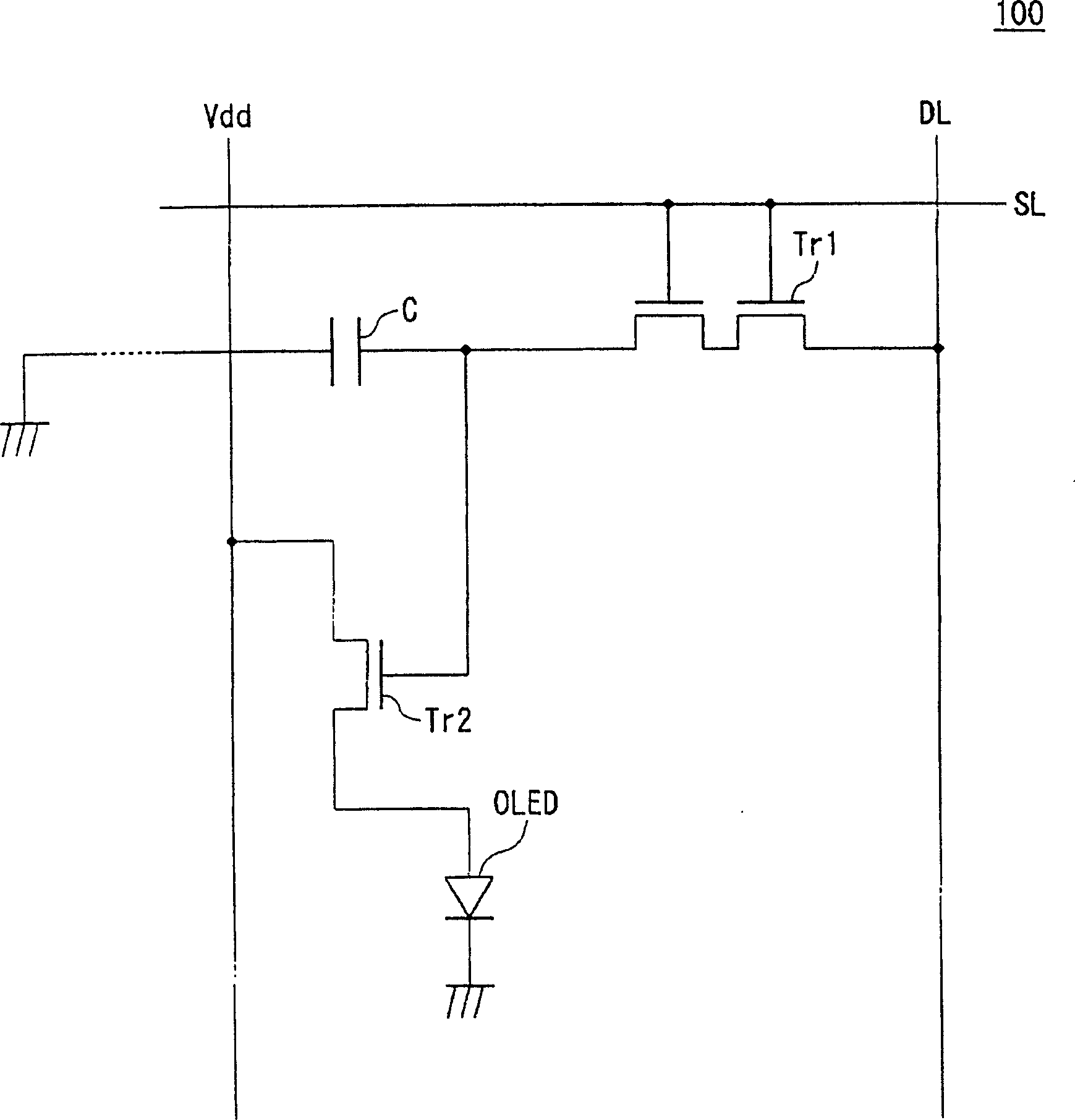

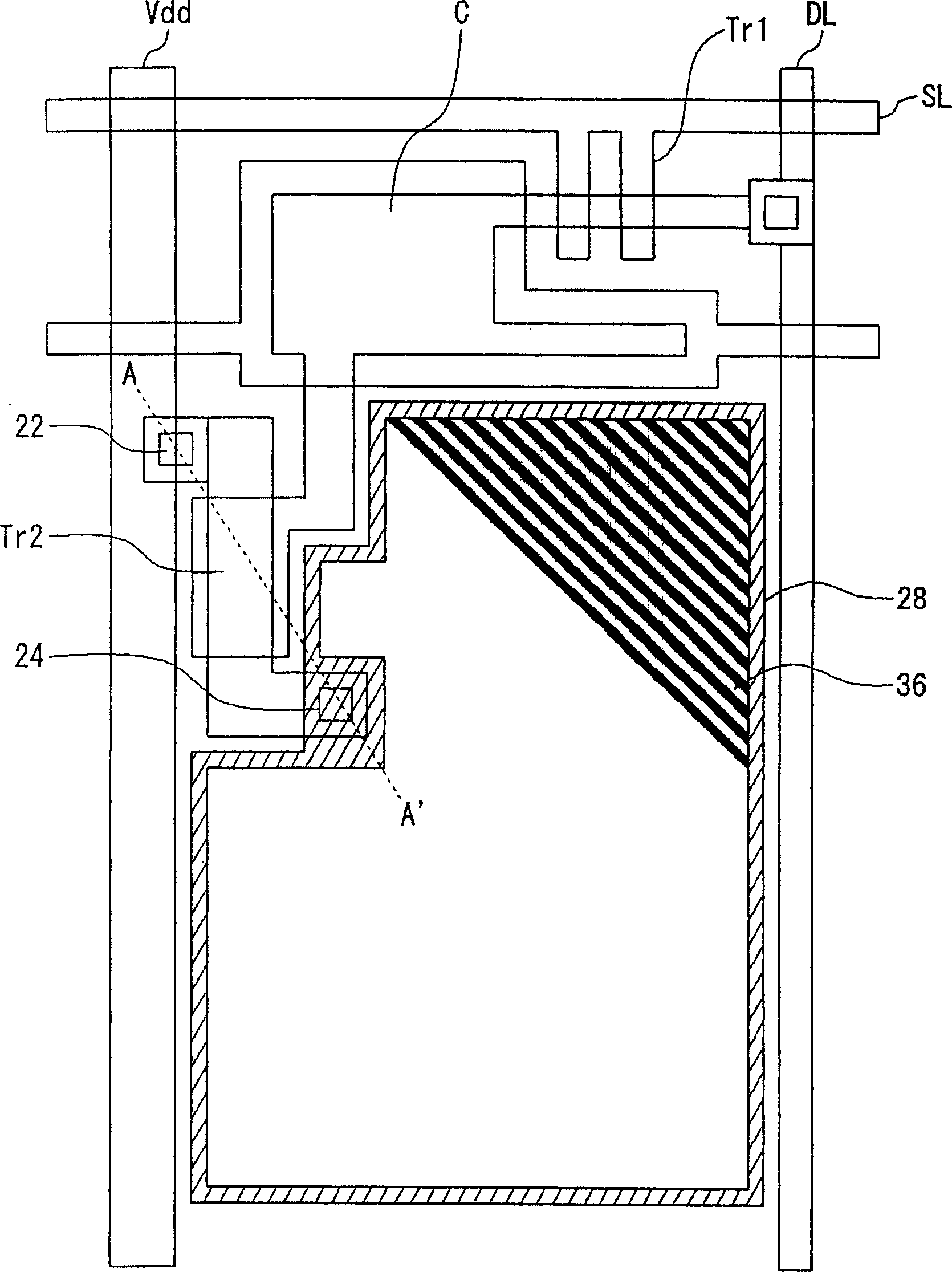

[0017] figure 1 is a circuit structure of a single pixel of the light emitter 100 of an embodiment. The circuit includes an organic light emitting element OLED, two transistors Tr for controlling the organic light emitting element OLED 1 and Tr 2 , a capacitor C, a scanning line SL for transmitting scanning signals, a data line DL for transmitting brightness data, and a power supply line Vdd for providing electric power.

[0018] The power line Vdd provides electric power to make the organic light emitting element OLED emit light. The data line DL transmits the set brightness data to the second transistor Tr 2 (hereinafter also referred to as "driving transistor"). The scan line SL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com