Preparation method of zno-ga polymer scintillation conversion screen

A polymer and conversion screen technology, which is applied in the direction of conversion screens, chemical instruments and methods, instruments, etc., can solve the problems of difficult ZnO-Ga crystal processing, difficulty in obtaining ZnO-Ga thin films, poor scintillation performance, etc., to achieve Good scintillation performance, short preparation cycle, optimized scintillation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, a method for preparing a ZnO-Ga polymer scintillation conversion screen includes the following steps:

[0032] 1) Preparation of ZnO-Ga nanocrystalline powder:

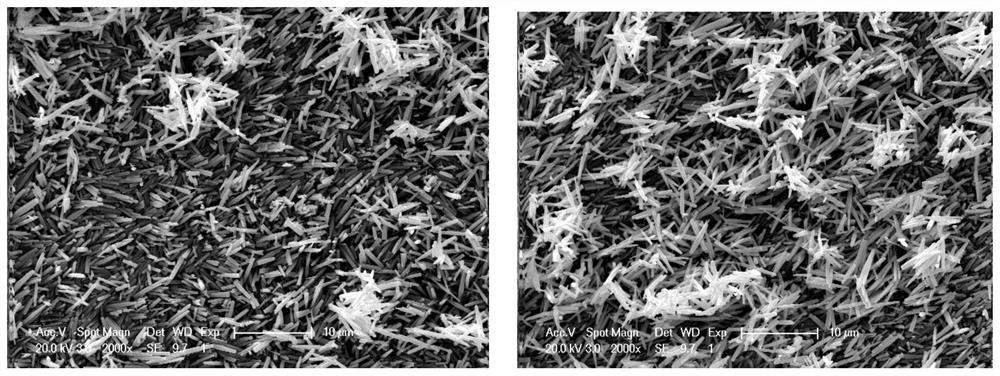

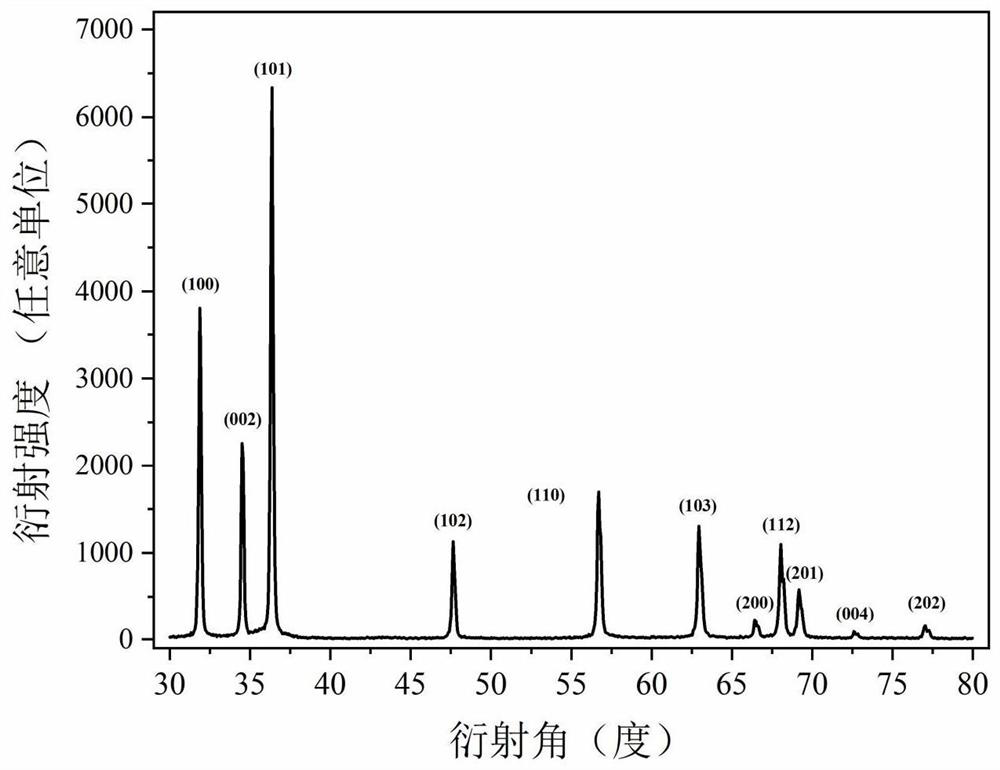

[0033] Take the chemical formula of 1.1780g as Zn(NO 3 ) 2 ·6H 2 O of zinc nitrate hexahydrate and 0.0102g of the chemical formula Ga(NO 3 ) 3 ·xH 2The hydrated gallium nitrate of O is put into 80ml of deionized water, and stirred at room temperature for 30min; then, take 0.5608g of chemical formula C 6 h 12 N 4 Put the hexamethylenetetramine into 80ml of deionized water, and stir for 30min at room temperature; pour the prepared two solutions into the hydrothermal reaction kettle in turn, seal the reaction kettle, put it in a vacuum drying oven, and heat Warm at 120°C for 12 hours to carry out hydrothermal reaction; after cooling down to room temperature, take out the precipitate and wash it with deionized water for 5 times to obtain ZnO-Ga single crystal nanorods;

[0034] 2) Multi...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, especially in that:

[0042] In this embodiment, a method for preparing a ZnO-Ga polymer scintillation conversion screen includes the following steps:

[0043] 1) Preparation of ZnO-Ga nanocrystalline powder:

[0044] The chemical formula of 9.424g is Zn(NO 3 ) 2 ·6H 2 O of zinc nitrate hexahydrate and 0.0818g of the chemical formula Ga(NO 3 ) 3 ·xH 2 The hydrated gallium nitrate of O is put into 80ml of deionized water, and stirred at room temperature for 30min; then, take 4.486g of chemical formula C 6 h 12 N 4 Put the hexamethylenetetramine into 80ml of deionized water, and stir for 30min at room temperature; pour the prepared two solutions into the hydrothermal reaction kettle in turn, seal the reaction kettle, put it in a vacuum drying oven, and heat Heat it at 120°C for 12 hours to carry out hydrothermal reaction; take out the precipitate after cooling down to room temperature, and wash it with deioni...

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

[0052] In this embodiment, a method for preparing a ZnO-Ga polymer scintillation conversion screen includes the following steps:

[0053] 1) Preparation of ZnO-Ga nanocrystalline powder:

[0054] Take the chemical formula of 1.1780g as Zn(NO 3 ) 2 ·6H 2 O of zinc nitrate hexahydrate and 0.0102g of the chemical formula Ga(NO 3 ) 3 ·xH 2 The hydrated gallium nitrate of O is put into 80ml of deionized water, and stirred at room temperature for 30min; then, take 0.5608g of chemical formula C 6 h 12 N 4 Put the hexamethylenetetramine into 80ml of deionized water, and stir for 30min at room temperature; pour the prepared two solutions into the hydrothermal reaction kettle in turn, seal the reaction kettle, put it in a vacuum drying oven, and heat Warm at 150°C for 20 hours to carry out hydrothermal reaction; take out the precipitate after cooling down to room temperature...

PUM

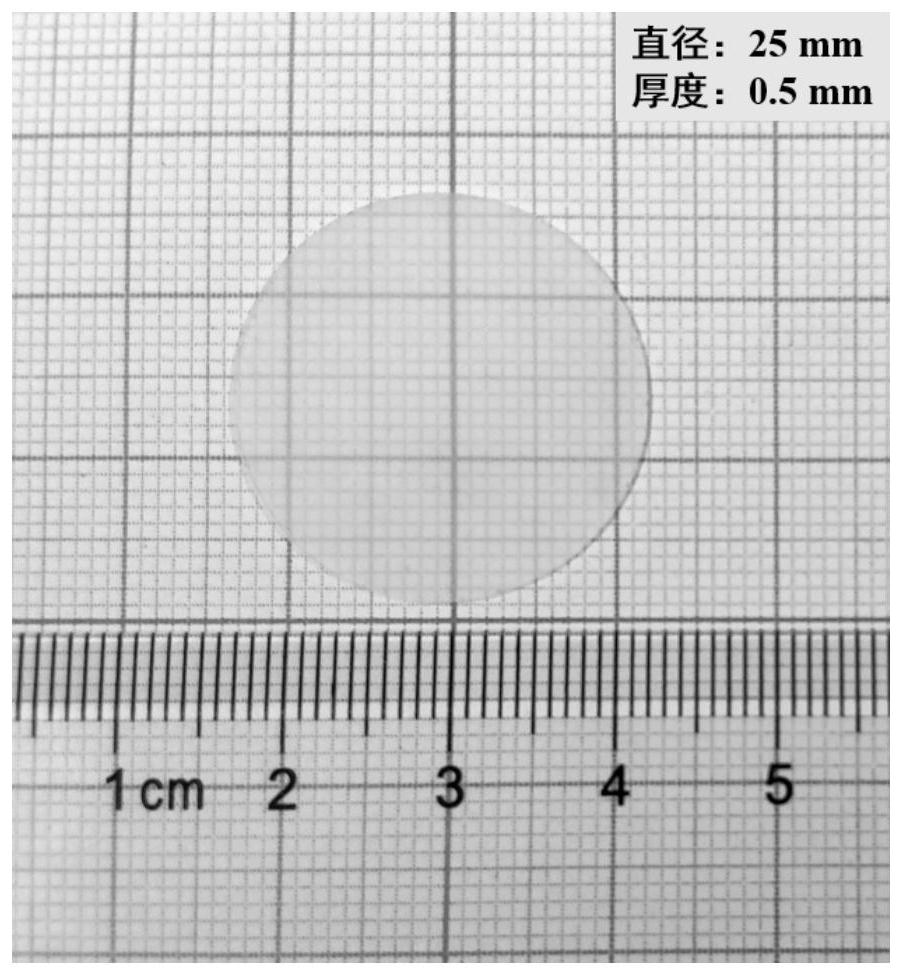

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com