Jacquard device of warp knitting machine

A warp knitting machine and jacquard technology, applied in warp knitting, textiles and papermaking, piezoelectric devices/electrostrictive devices, etc., can solve problems such as failures and troubles, improve durability, improve safety, and prevent leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

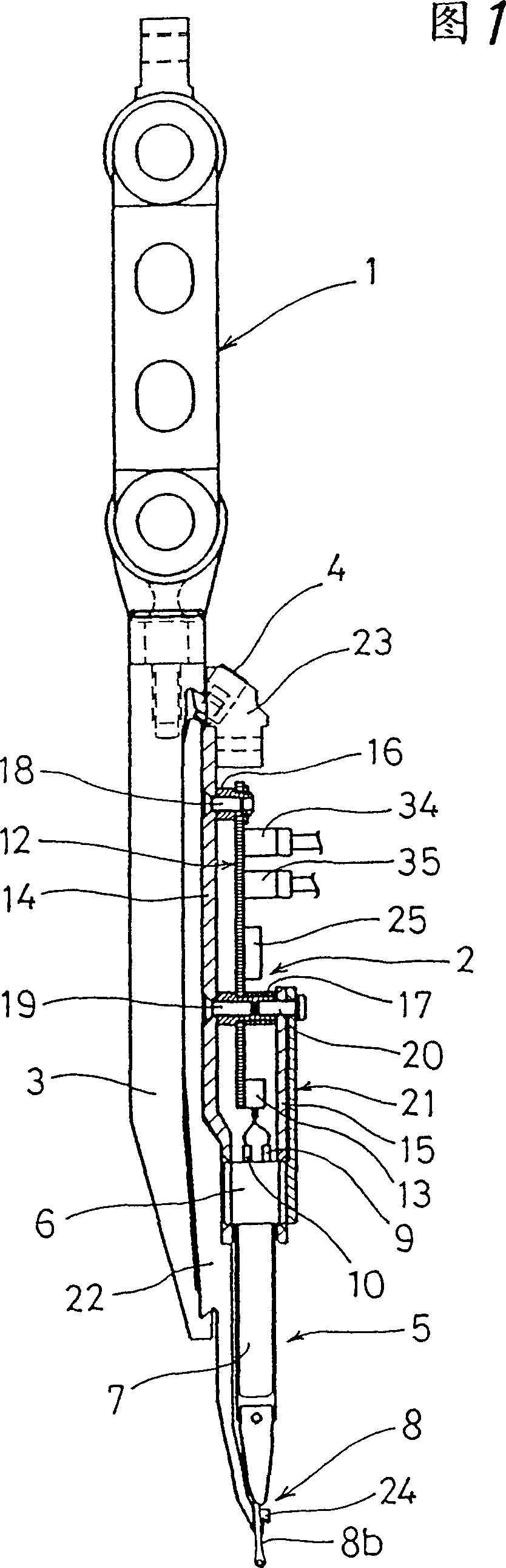

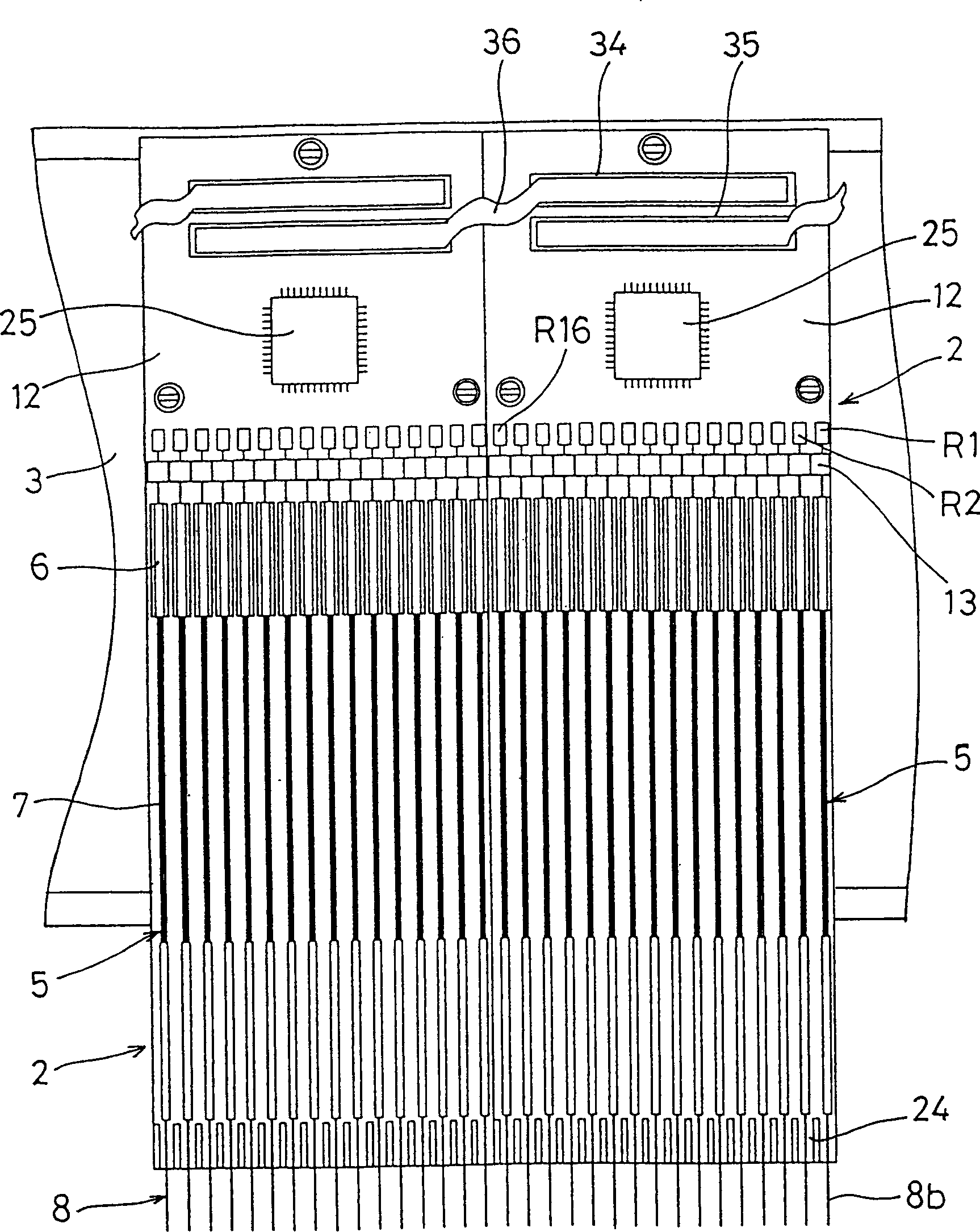

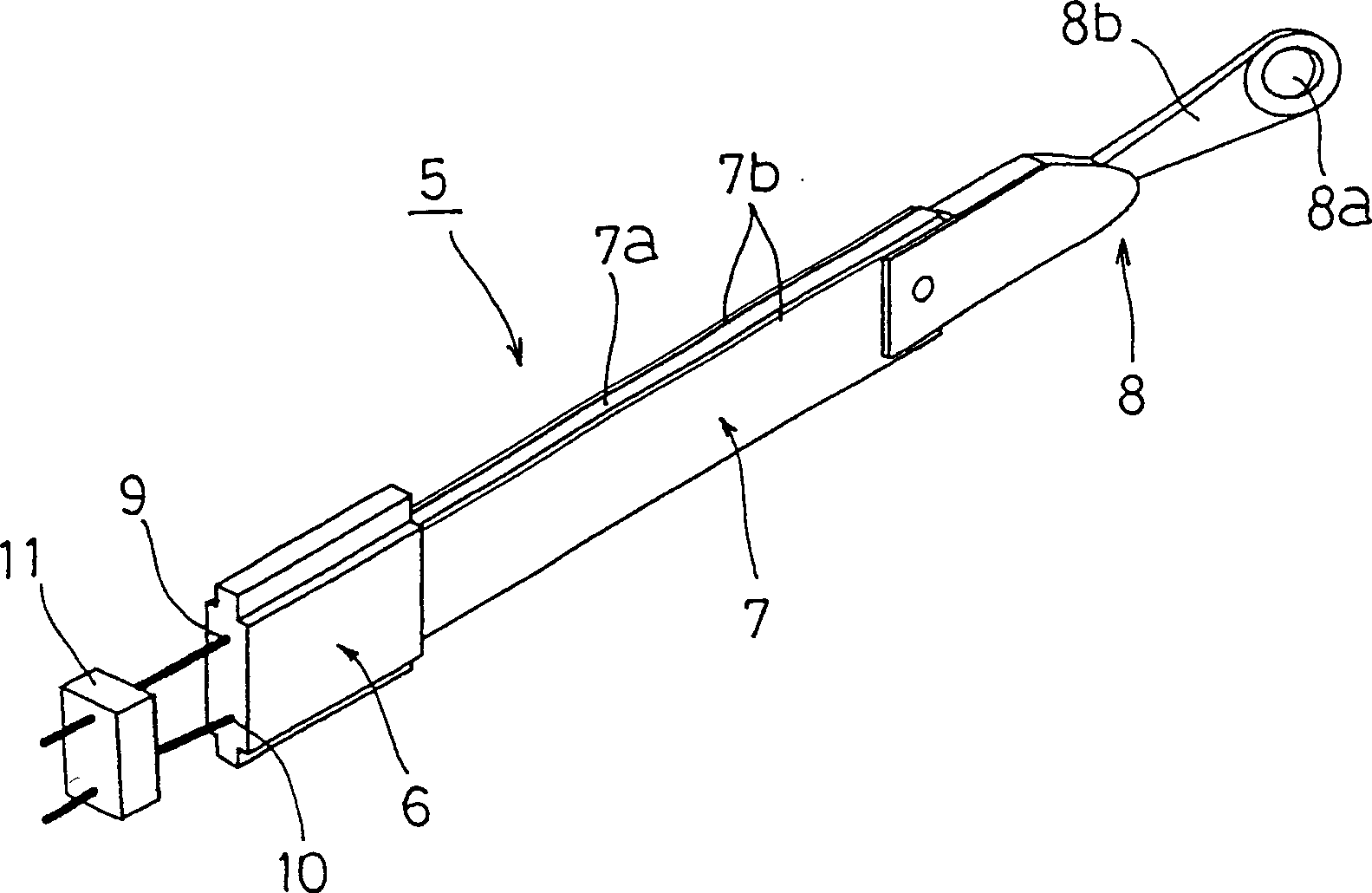

[0029] Referring to Figure 1- Figure 6 Embodiments of the device of the present invention will be described.

[0030] Fig. 1 shows the structure of the jacquard guide bar of an embodiment of the device of the invention with a piezoelectric actuator in partial section, figure 2 It shows the state where a plurality of jacquard components are mounted on the mounting part of the jacquard guide bar, image 3 It shows the single body of the piezoelectric element embedded in the jacquard guide bar, Figure 4 The jacquard thread guide section is shown.

[0031] As shown in the figure, symbol 1 is the jacquard guide bar. Symbol 2 is a jacquard assembly, and the installation part 3 arranged along the length direction is fixed by a screw 4 at one end (mainly the lower end) of the jacquard guide bar 1 in the width direction.

[0032] Above-mentioned jacquard component 2 such as figure 2 As shown, a plurality of attachment portions 3 of the jacquard guide bar 2 are attached in a row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com