Magnetic material bottom filling method in chip packaging

A magnetic material and bottom filling technology, which is applied in the field of magnetic material bottom filling and controlled bottom filling magnetic composite materials, can solve the problems of reducing filling time, achieve the effects of reducing filling time, improving device reliability, and avoiding accumulation and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

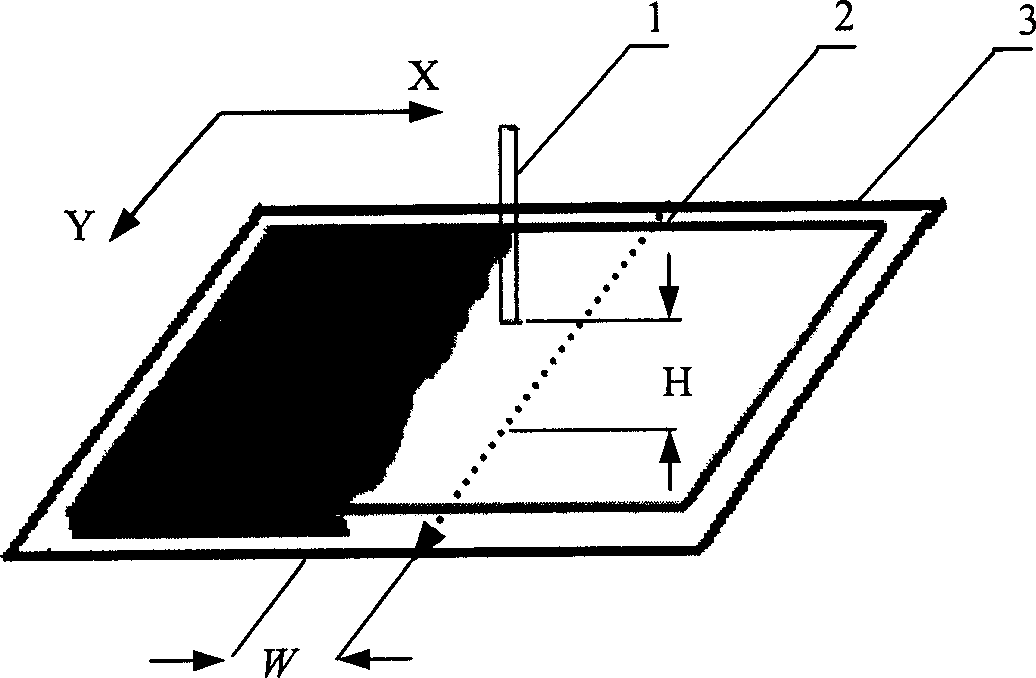

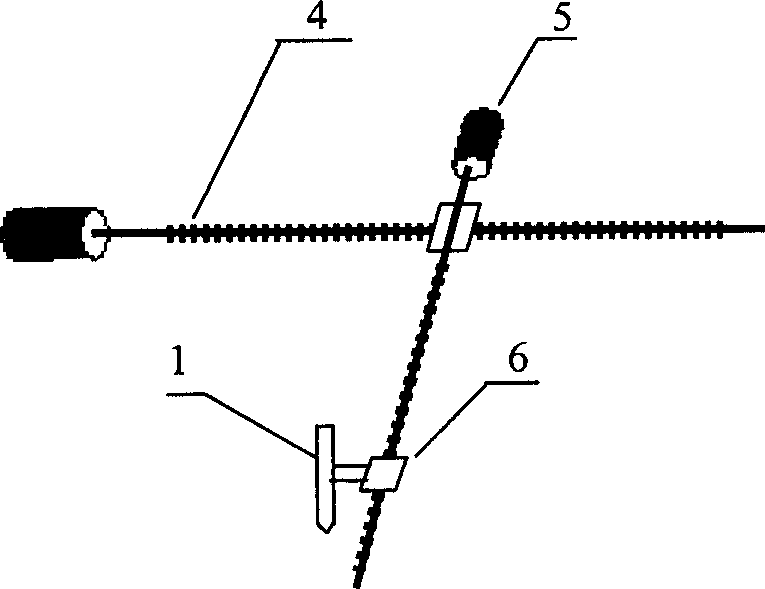

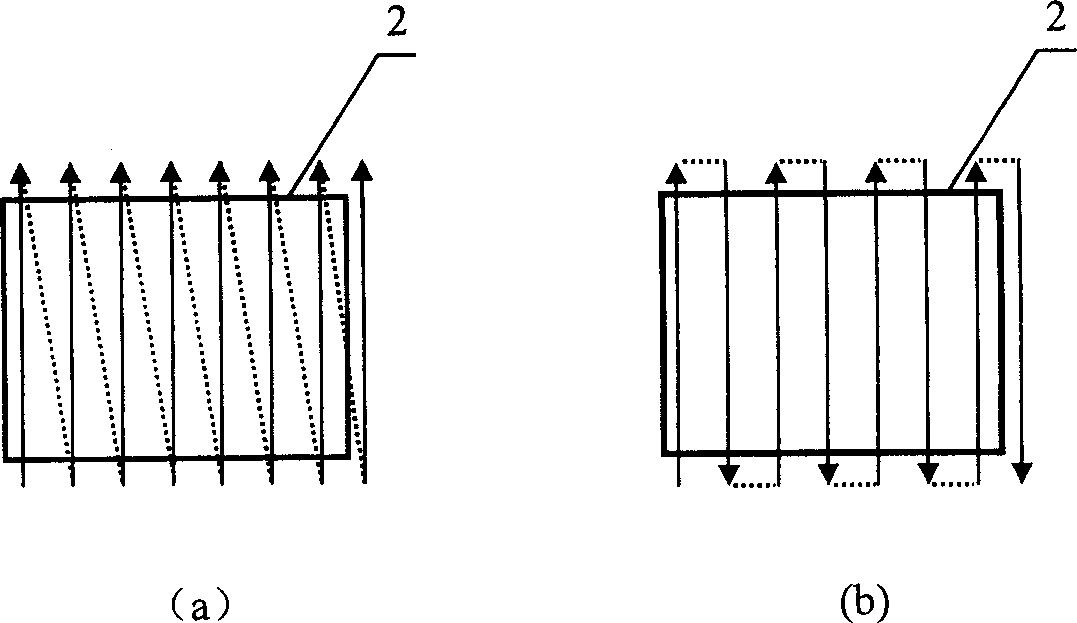

[0021] Main implementation method of the present invention is as follows:

[0022] 1. Selection of magnetic materials and preparation of magnetically filled composite materials

[0023] Alternative magnetic materials include inorganic magnetic materials and organic magnetic materials. The bottom filling material used in the present invention is a soft magnetic composite material containing magnetic powder. The magnetic powder is required to have low remanence and high resistivity. The Curie temperature is lower than that of commonly used inorganic magnetic materials to ensure that the magnetic composite material filled between the chip and the substrate is weakened or even completely demagnetized after curing. The metallocene polymer magnet synthesized from metallocene is black powder (fine powder). The powder is a soft magnetic material with high magnetic permeability, high resistivity, low remanence, and the Curie temperature is much lower than other Inorganic magnetic mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com