Electrostatic discharge protection on circuit board

A technology for electrostatic discharge protection and circuit boards, which is applied in the direction of static electricity, circuits, and electrical components, and can solve problems such as the failure of the main circuit board 100 to operate normally, processor or chip damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

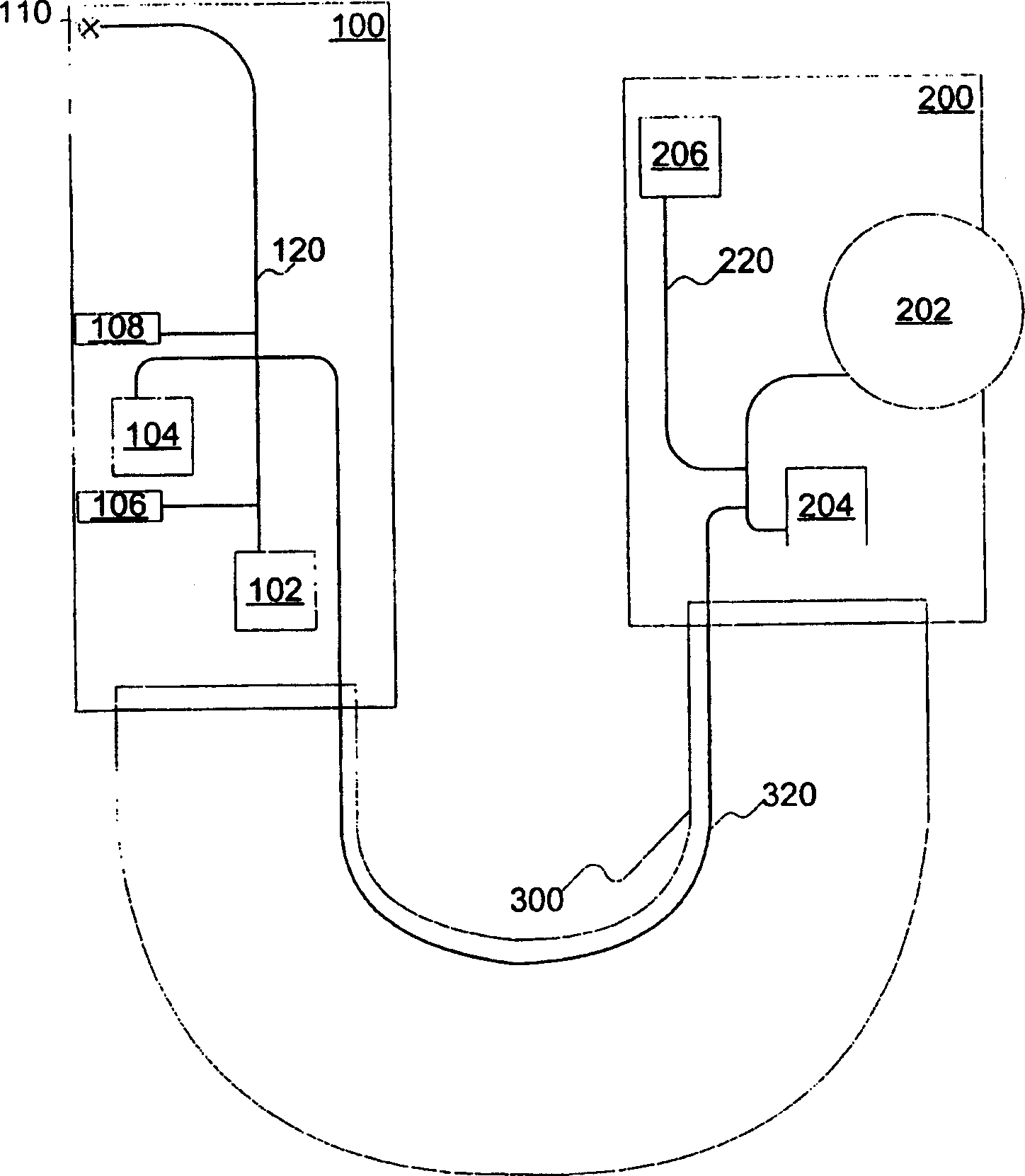

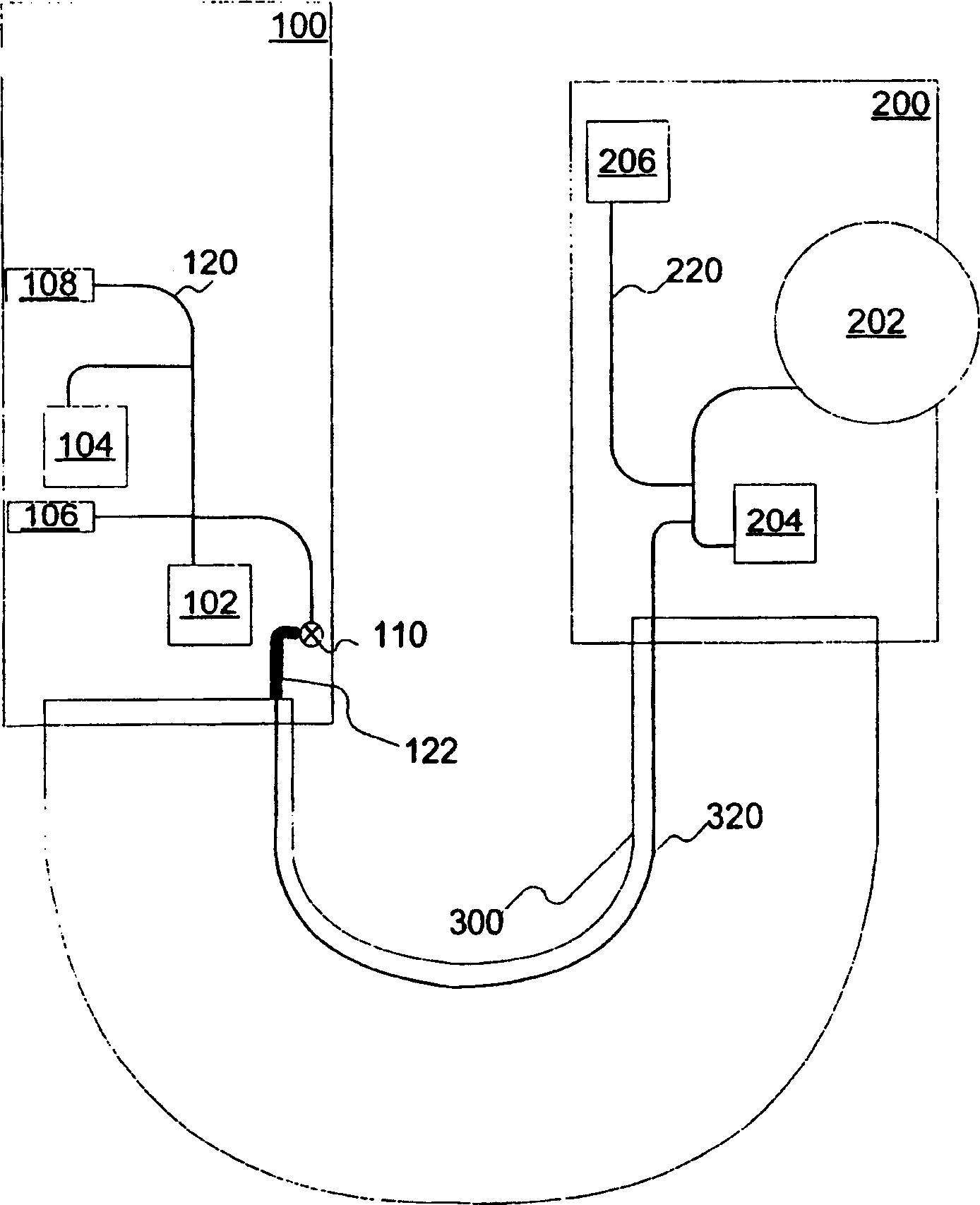

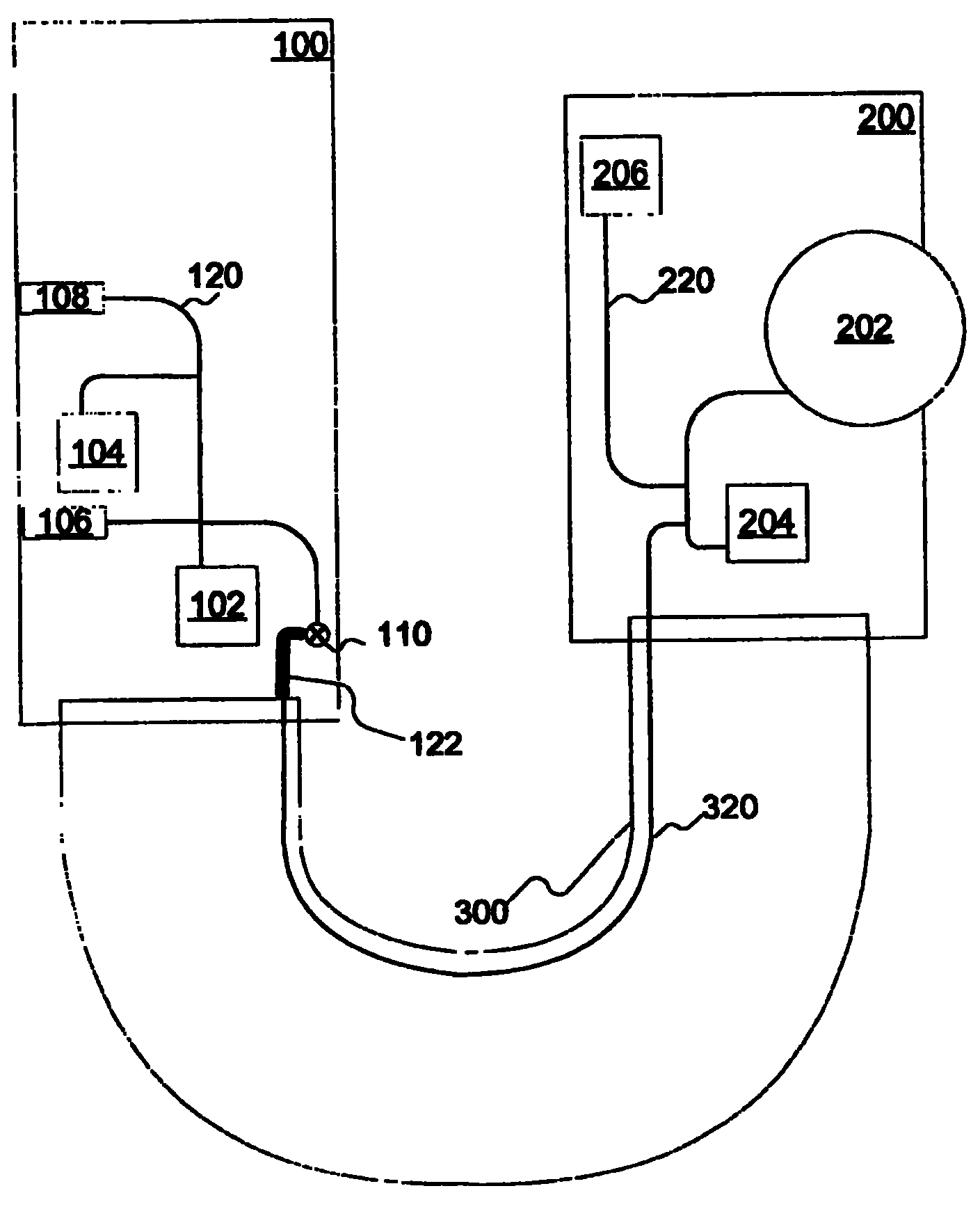

[0020] Please refer to figure 2 , which represents a schematic diagram of circuit board wiring of the thin optical disk device of the present invention. The circuit board of the thin disc device can be divided into two parts, the sub-board (Sub-Board) 200 is fixed on the movable tray (Tray), and the main circuit board (Main Board) 100 is fixed on the casing.

[0021] The present invention first designs an electrostatic discharge protection path 122 on the circuit layout of the main circuit board 100, one end of which is connected to a connection line 320 in the U-shaped flexible cable 300, and the connection line 320 is connected to the ground on the sub-circuit board 200. Line 220 is connected. The other end is directly connected to the screw 110 . According to the embodiment of the present invention, the ESD protection path 122 has a wider line width of 0.75mm, but the above width limit is for reference only, in fact, as long as the line width is greater than the minimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com