Husking-roller burnout prevention device in huller

A husking roller and husking machine technology, which is applied in grain husking, grain processing, grain pod removal, etc., can solve the problems of durability not suitable for actual use and wear, and achieve improved reliability, improved durability, and prevention of deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

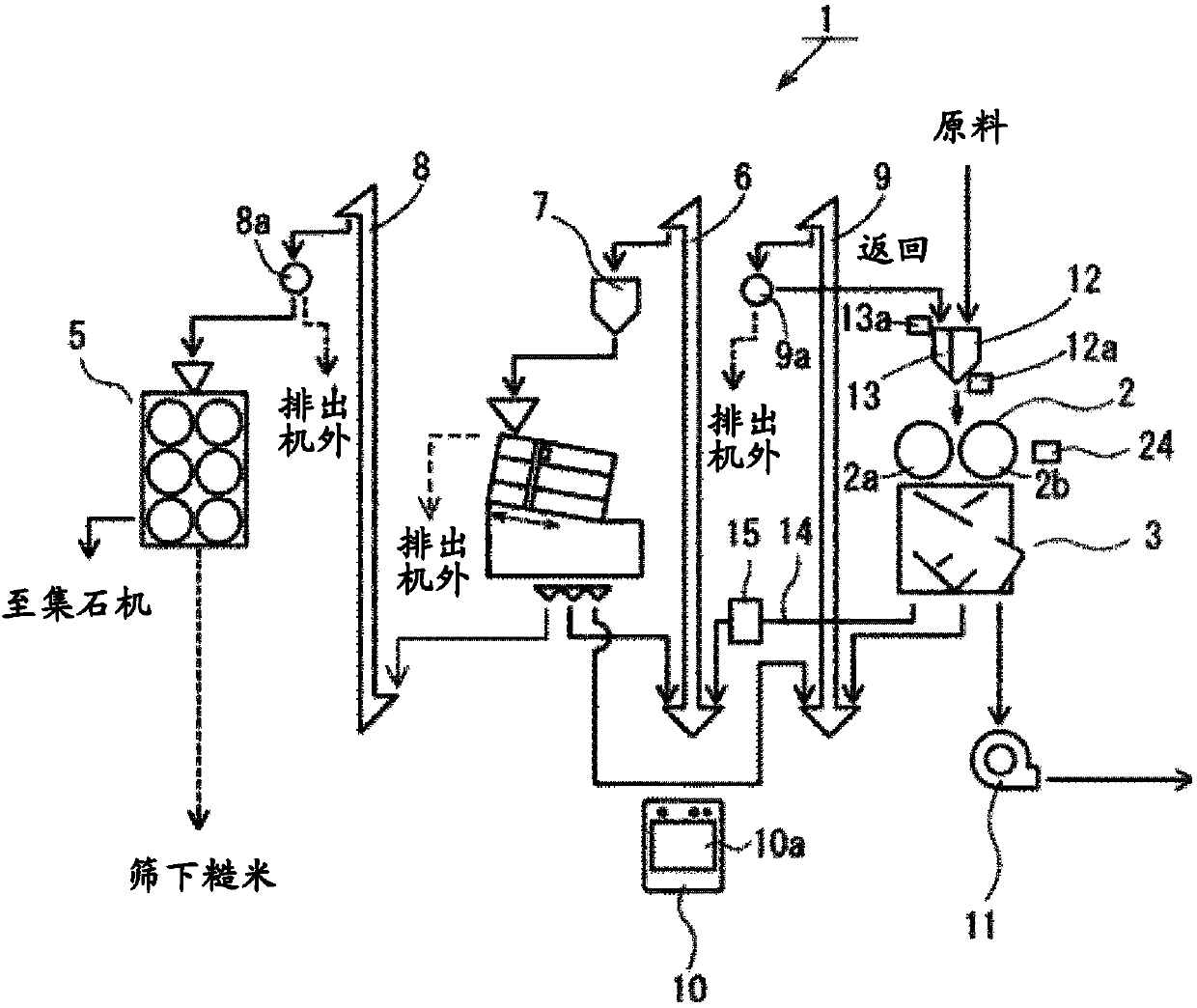

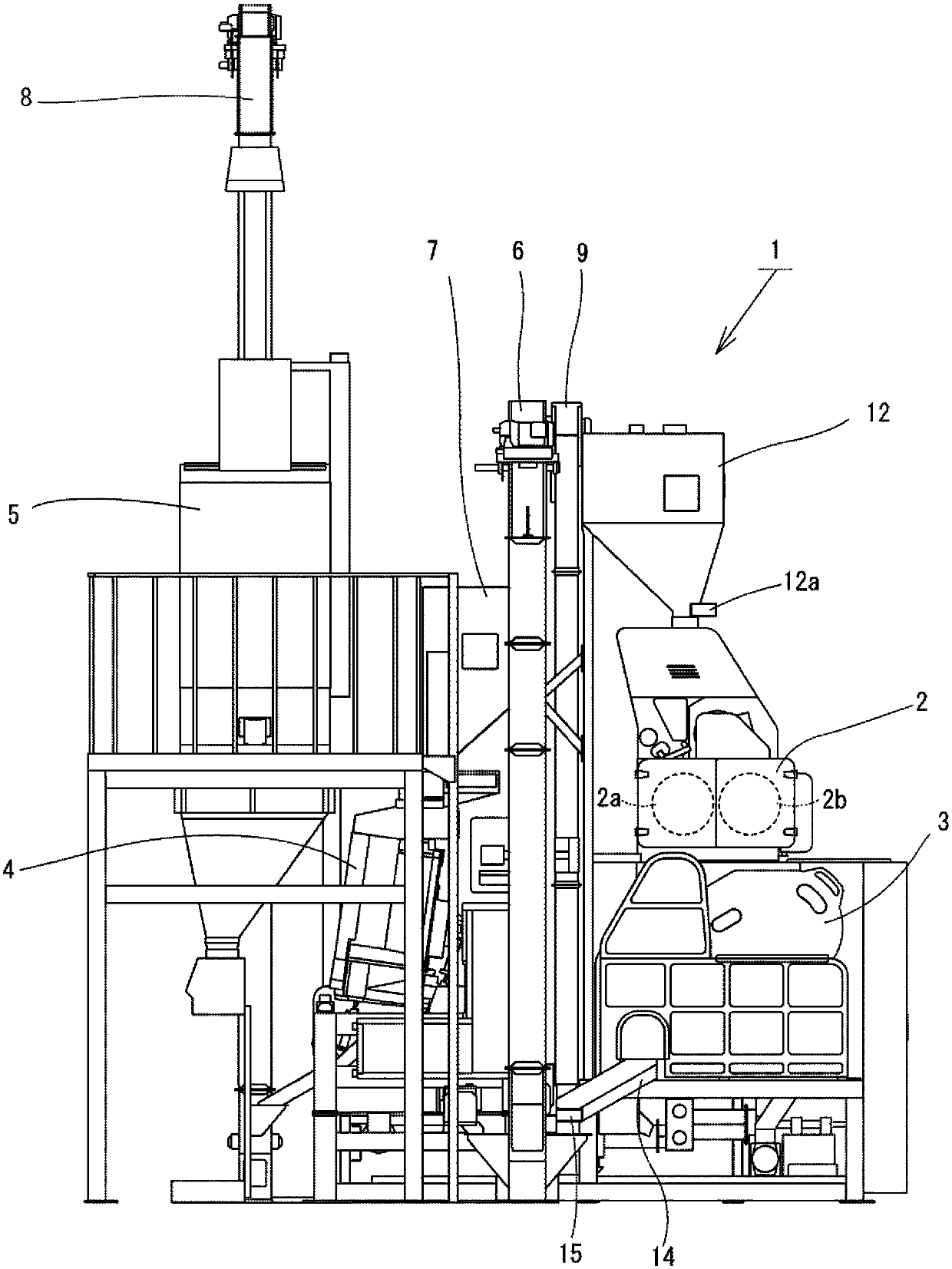

[0031] Hereinafter, preferred embodiments of the present invention will be described based on the drawings. figure 1 It is a flow chart showing the flow of each process of the rice hulling machine, figure 2 It is a front view showing the appearance of the paddy huller.

[0032] Such as figure 1 as well as figure 2 Shown, the main part of paddy hulling machine 1 of the present invention has: the husking part 2 that is made of a pair of husking rollers 2a, 2b; The winnowing section 3 for light inclusions; the swing sorting section 4 for sorting the mixed rice after winnowing into paddy, brown rice and mixed rice by using the swing sorting action; and the sorted brown rice Grain sorting section 5 for sieving full-grain whole grains and immature grains.

[0033] The above-mentioned husking part 2 and winnowing part 3 are reset and formed into an integrated structure, and the winnowing part 3 and the swing sorting part 4 are connected via a rice mixing machine 6 and a mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com