Motor/generator and accessory belt drive system

A drive system, generator technology, applied in the direction of motor starting, engine starting, machine/engine, etc., can solve the problem that the length is not optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

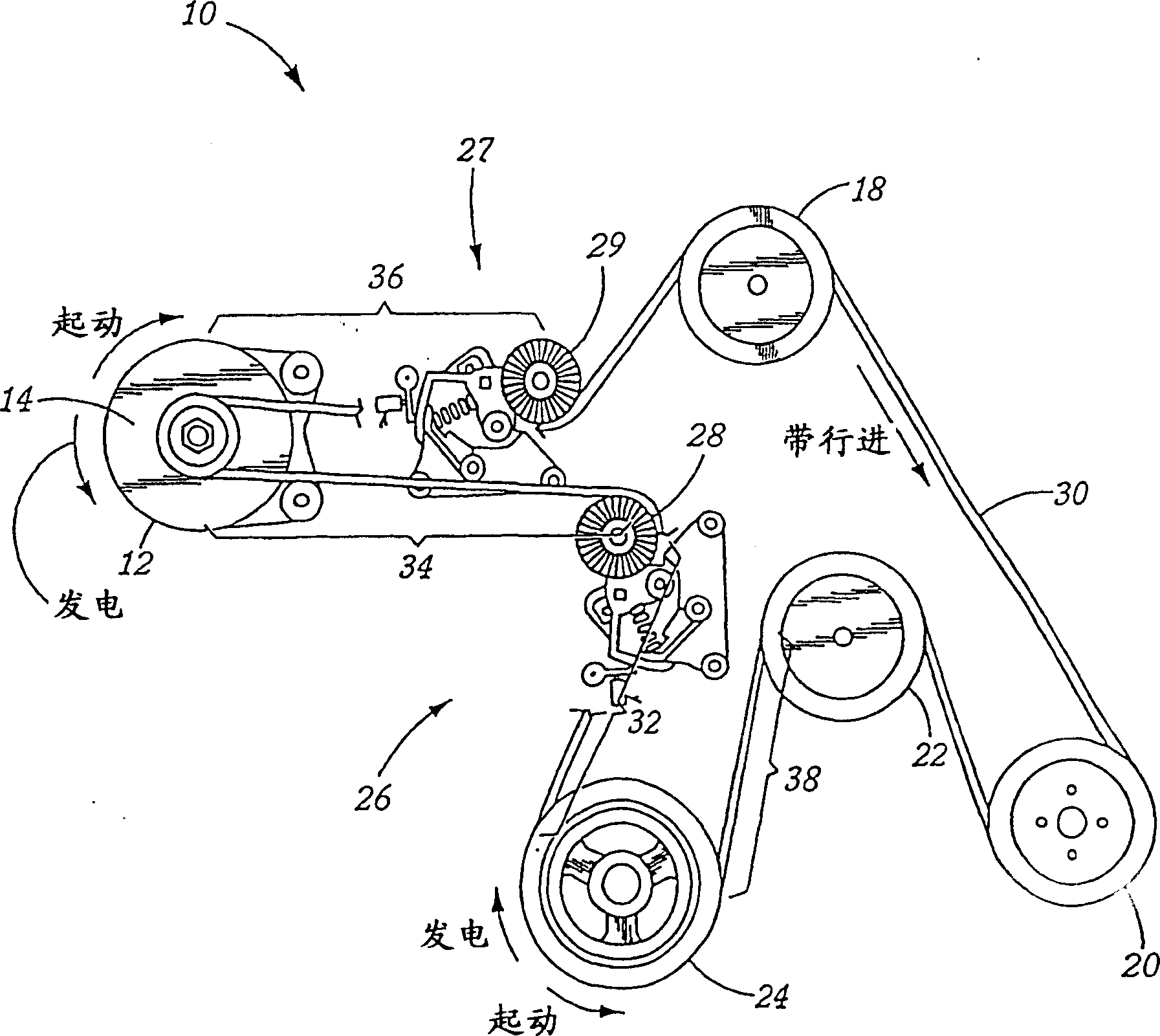

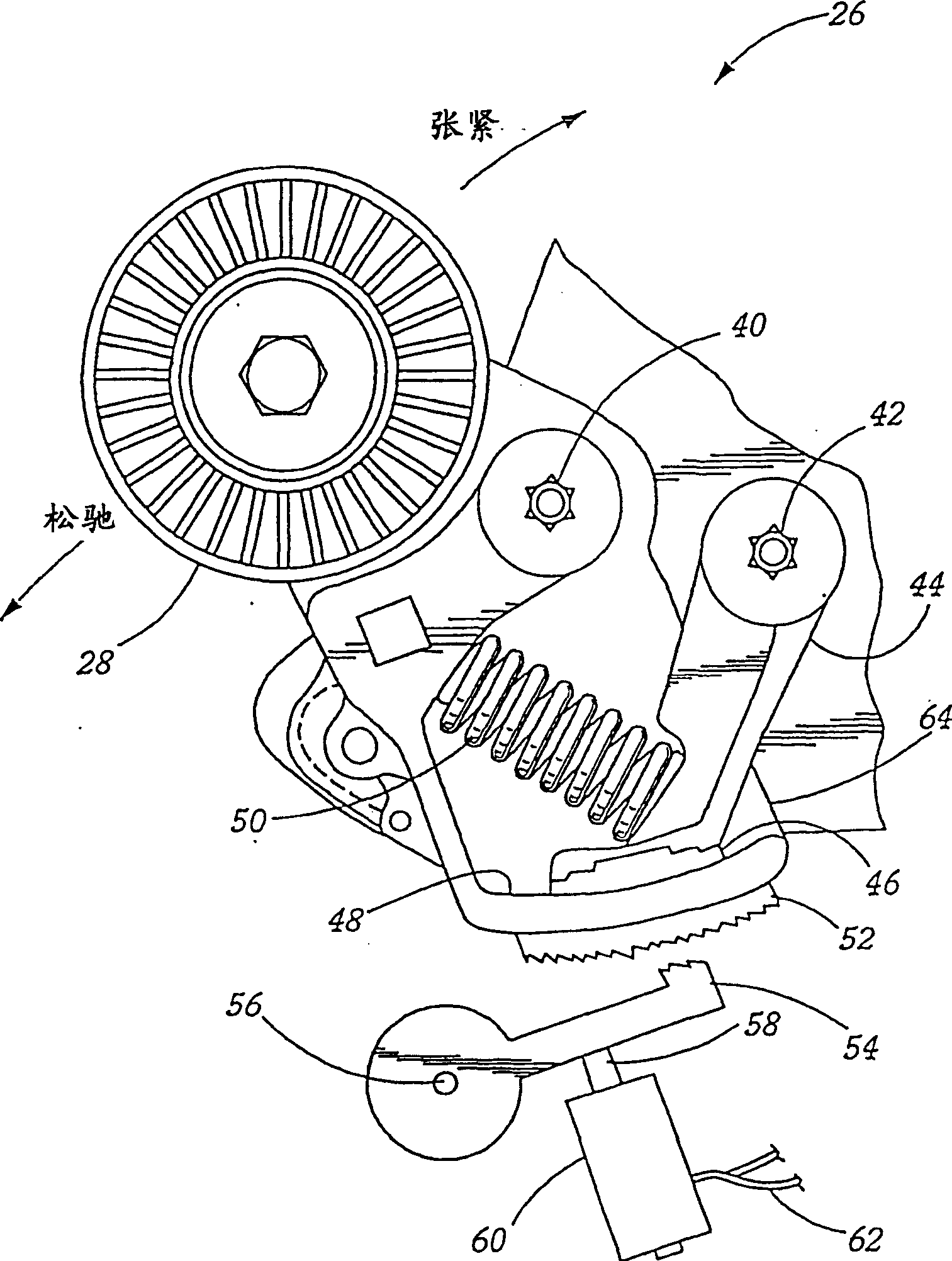

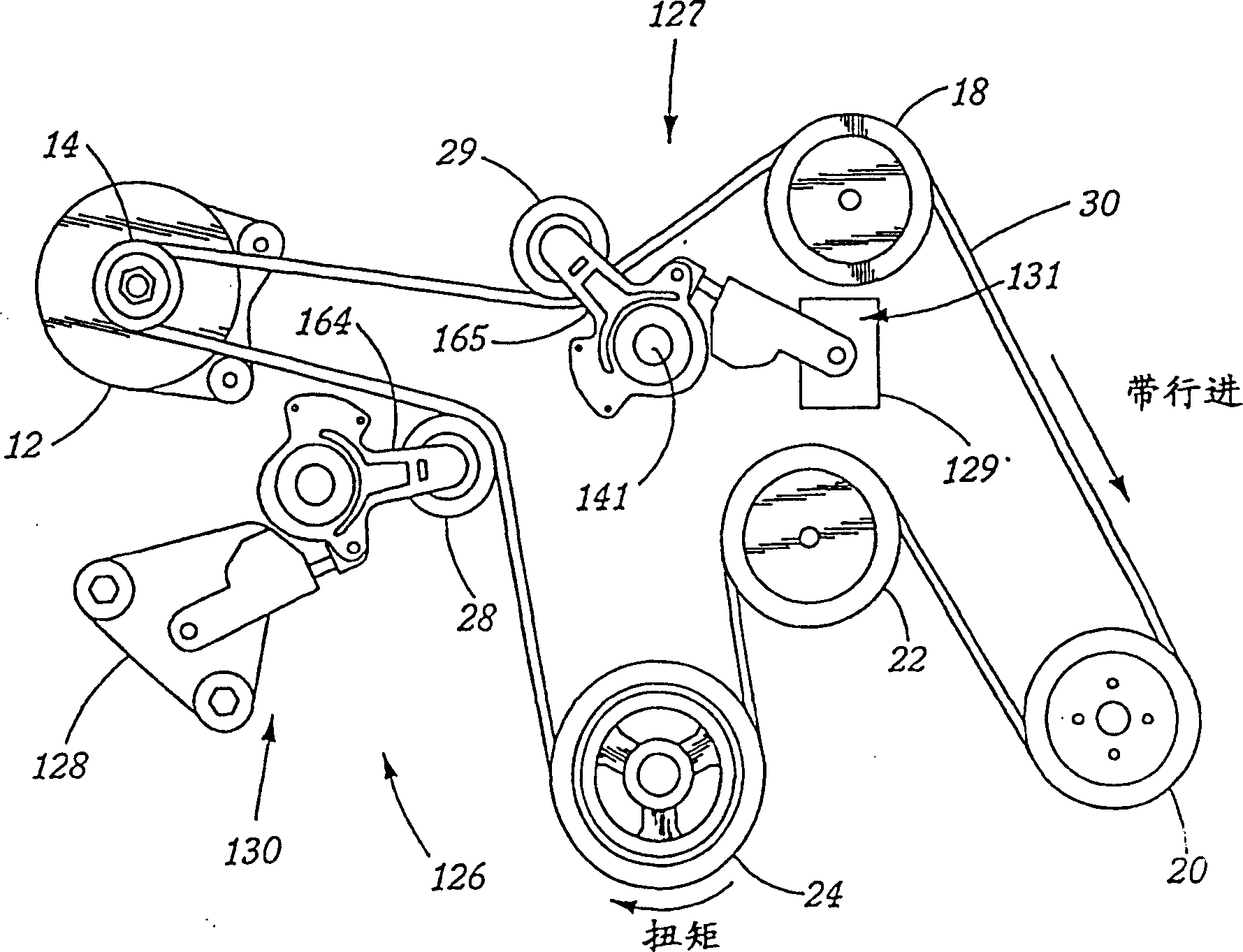

[0031] figure 1 A preferred embodiment of the auxiliary belt drive system 10 is shown in . It includes motor / generator 12, motor / generator pulley 14, power steering pump pulley 18, air conditioning compressor pulley 20, water pump pulley 22, crankshaft pulley 24, first tensioner 26, first tensioner 28, The second tensioning device 27 , the second tensioning pulley 29 and the power transmission belt 30 . The portion of the power transmission belt 30 that would obscure the first tensioner 26 or the second tensioner 27 is broken in the figure.

[0032] Although specific auxiliary pulleys are described for use in specific geometric arrangements, it should be recognized that the invention is applicable to various combinations of auxiliary devices and geometric arrangements, including serpentine and non-serpentine configurations, depending on the particular application . The described structure is serpentine. Therefore, the power transmission belt 30 is generally a v-rib type. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com