Motion-transfering device of motor-vehicle fan co-axially operated with connection system

A coolant and motor vehicle technology, applied in the direction of coolant flow control, power plant, power plant cooling combination layout, etc., can solve the problems of impossibility to realize the fan no-load condition, increase of production cost, high responsibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

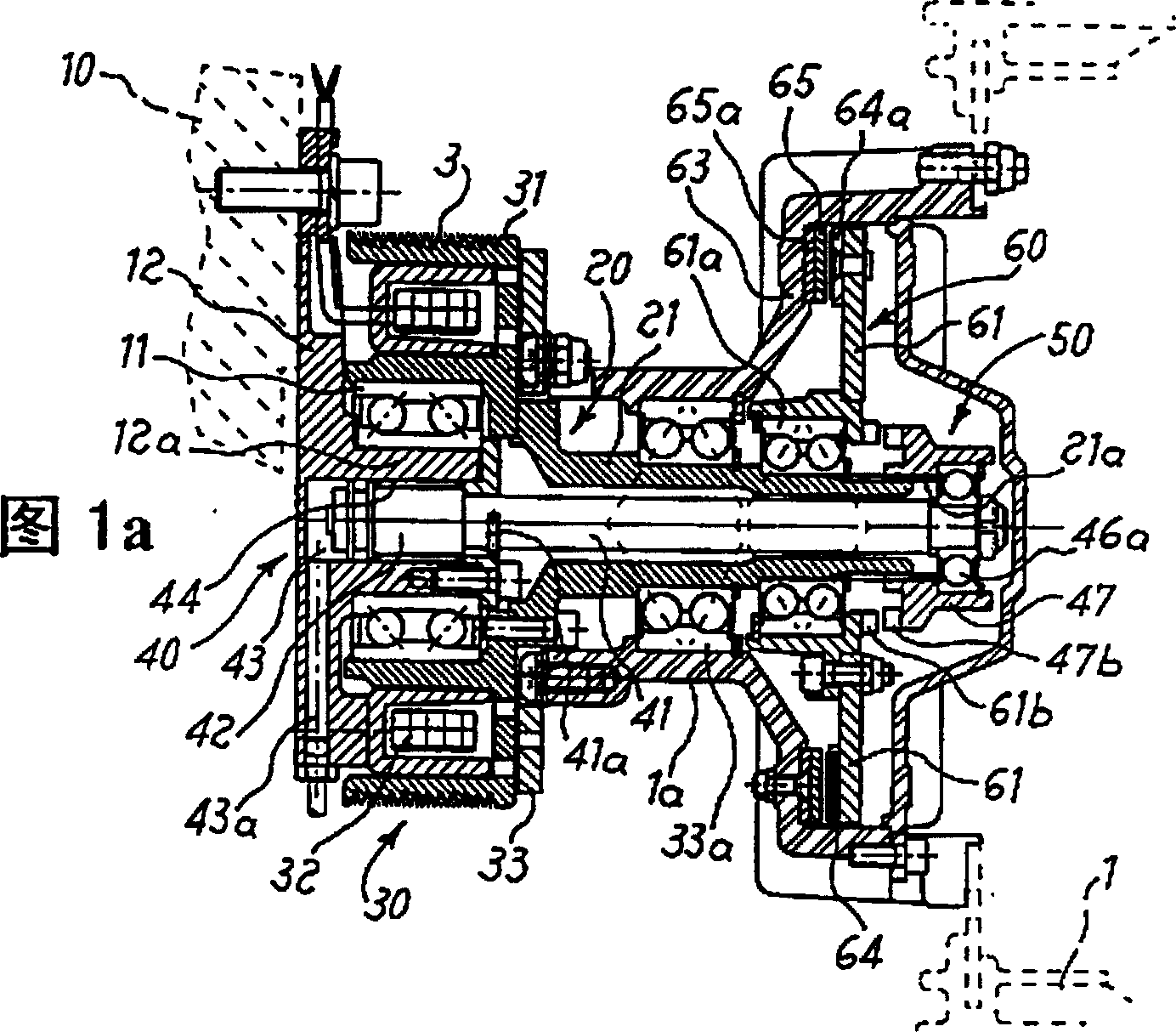

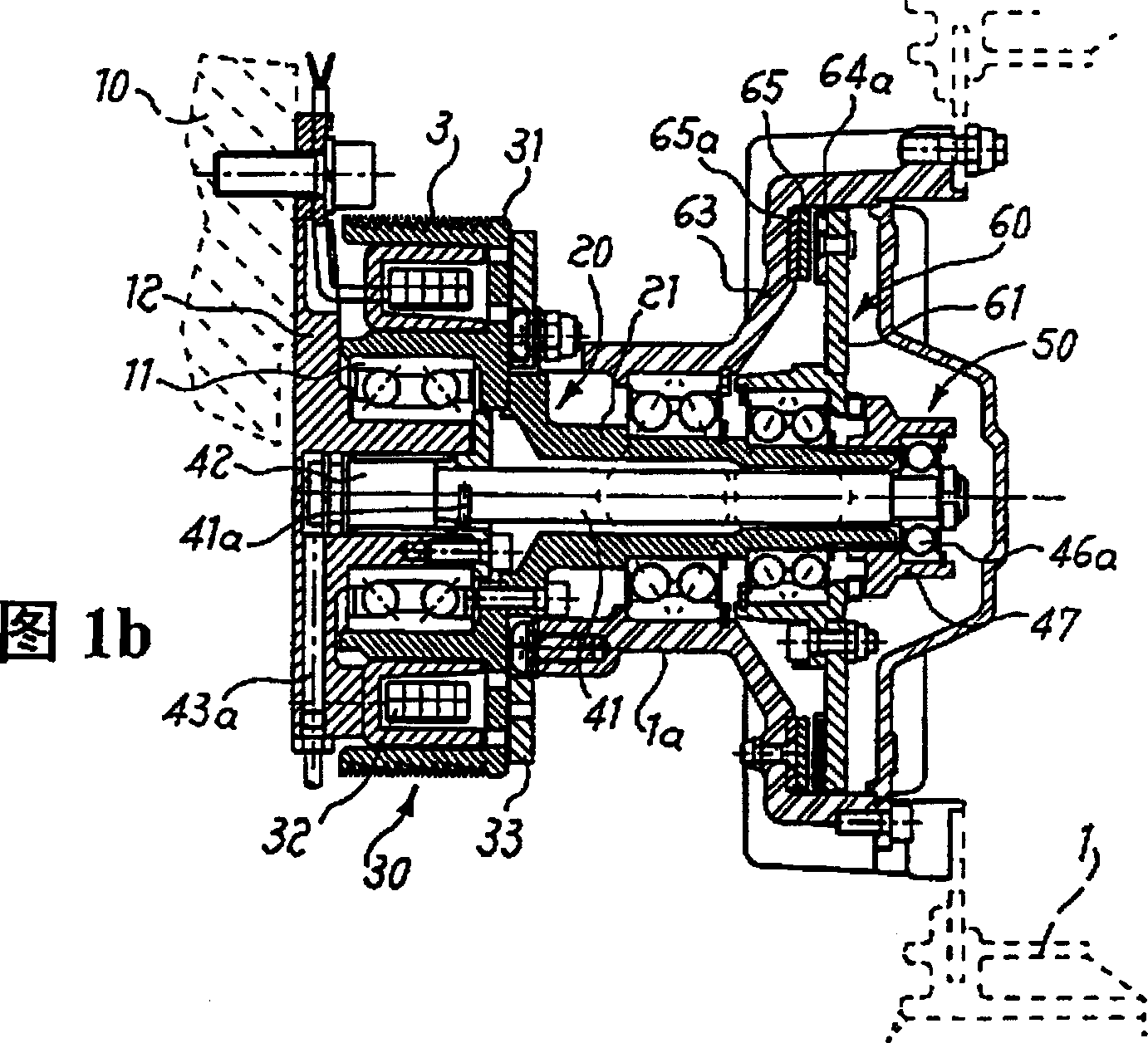

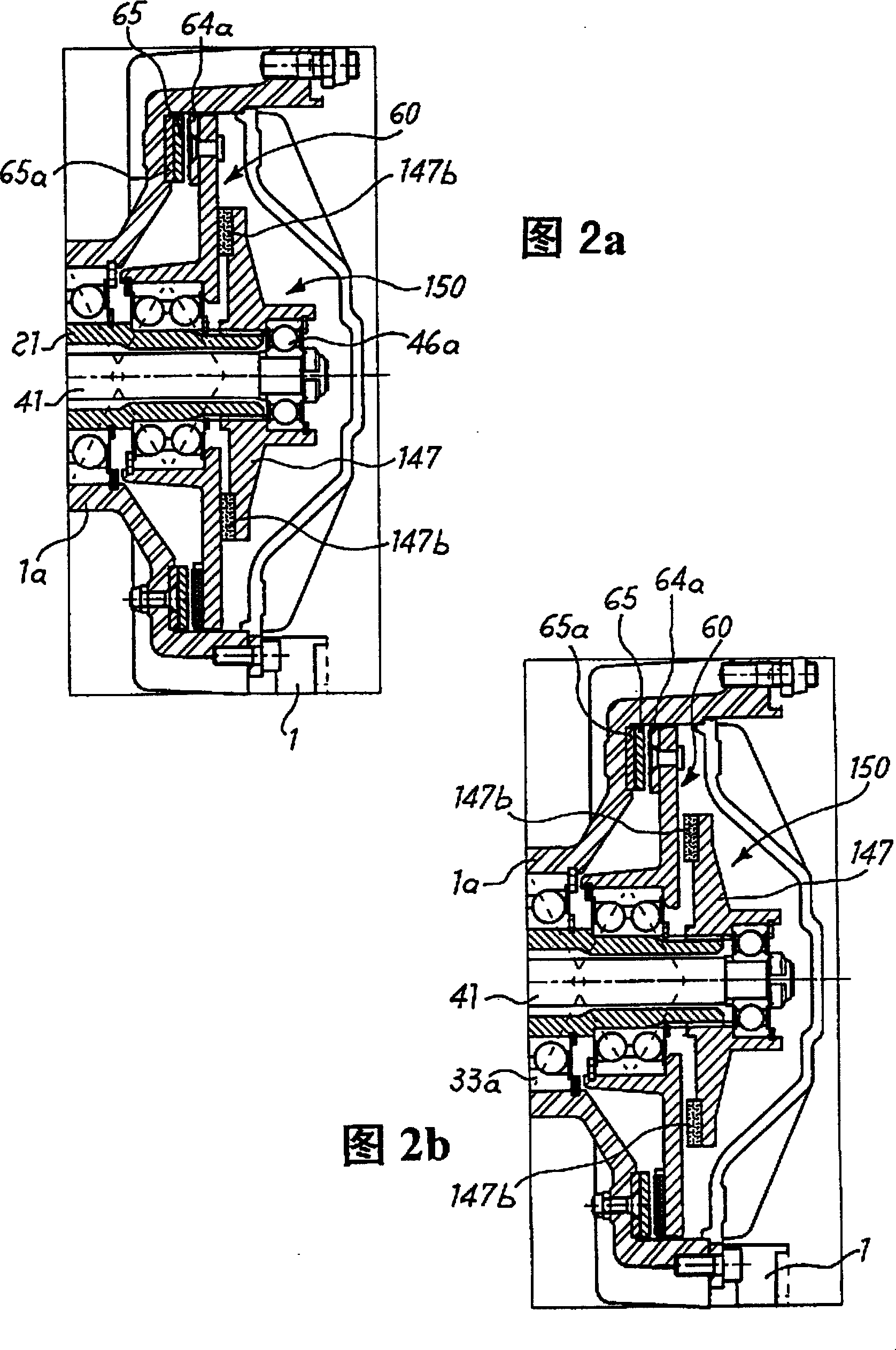

[0023] As shown in Figures 1a, 1b, the means for transmitting motion to the motor vehicle cooling fan 1 is installed between the fan 1 itself and a transmission shaft 20 integral with a pulley 3 connected to the crankshaft by a belt (not shown), For the convenience of description below, "longitudinal" will be understood as a direction parallel to the longitudinal axis of the transmission shaft 20 .

[0024] In further detail, the transmission shaft comprises a hollow bushing 21, one end of which is connected to a rotor 31 integral with the pulley 3, said rotor being mounted on a bearing 11 keyed to the On a suitable hollow extension 12a of a support flange 12 integrally connected with the base body 10 of the engine.

[0025] The rotor 31 constitutes the rotating element of the electromagnetic clutch 30 formed by an annular electromagnet 32, the annular electromagnet 32 is concentric with the rotor 31, the electromagnet is placed between the rotor 31 and the fixed flange 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com