Drilling and reaming machine

A technology of drilling, expanding and drilling bits, which is applied in the directions of rotary drilling rigs, drilling bits, and earth-moving drilling and mining, etc., can solve the problems of slow speed, reduced pile bearing capacity, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

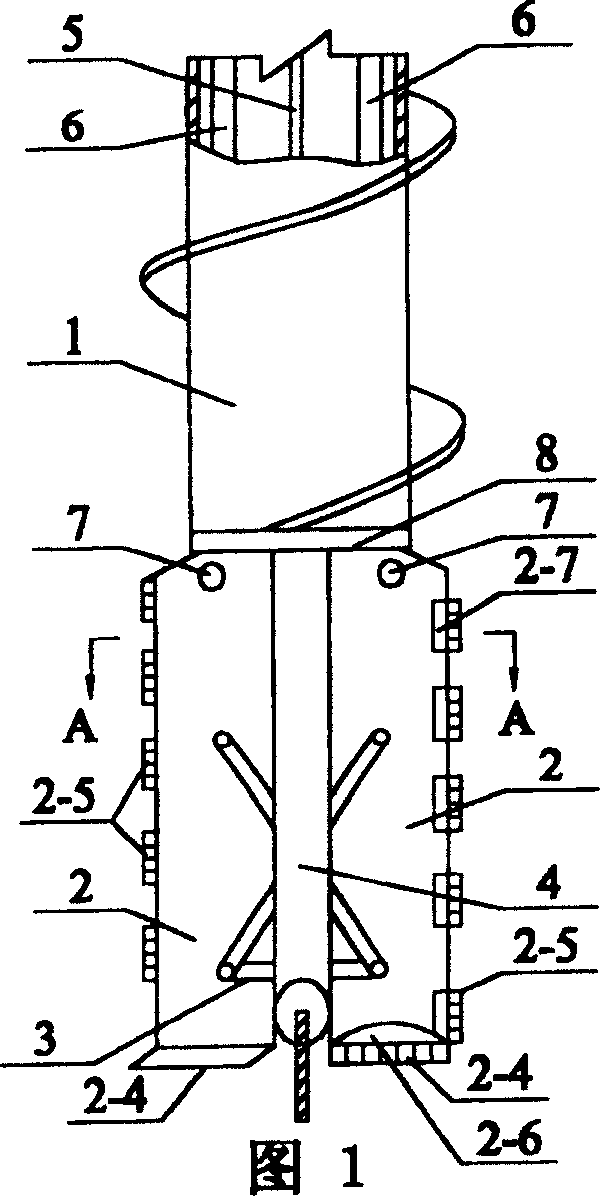

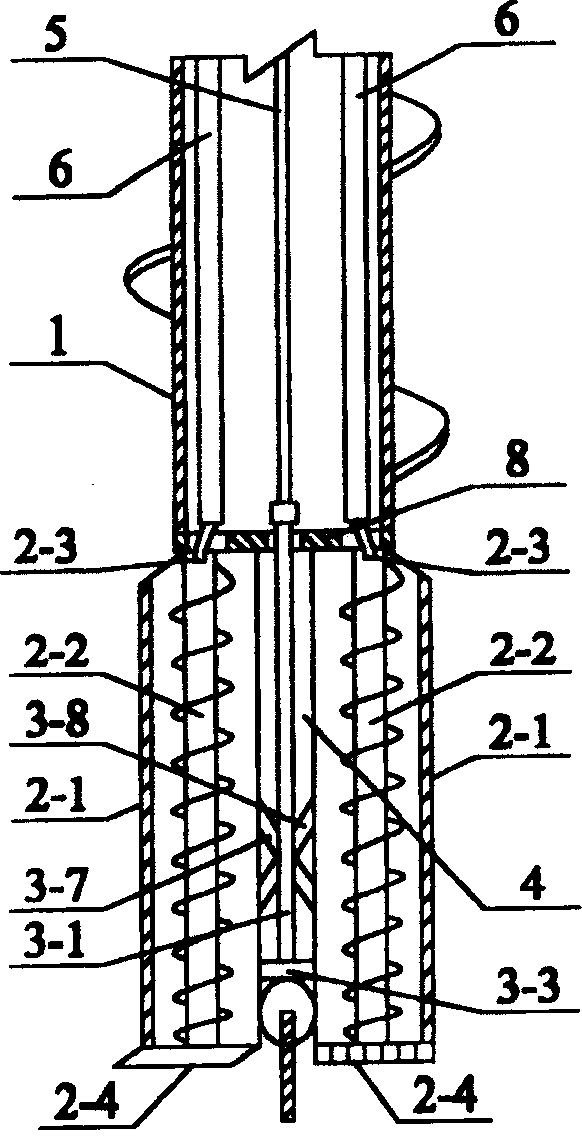

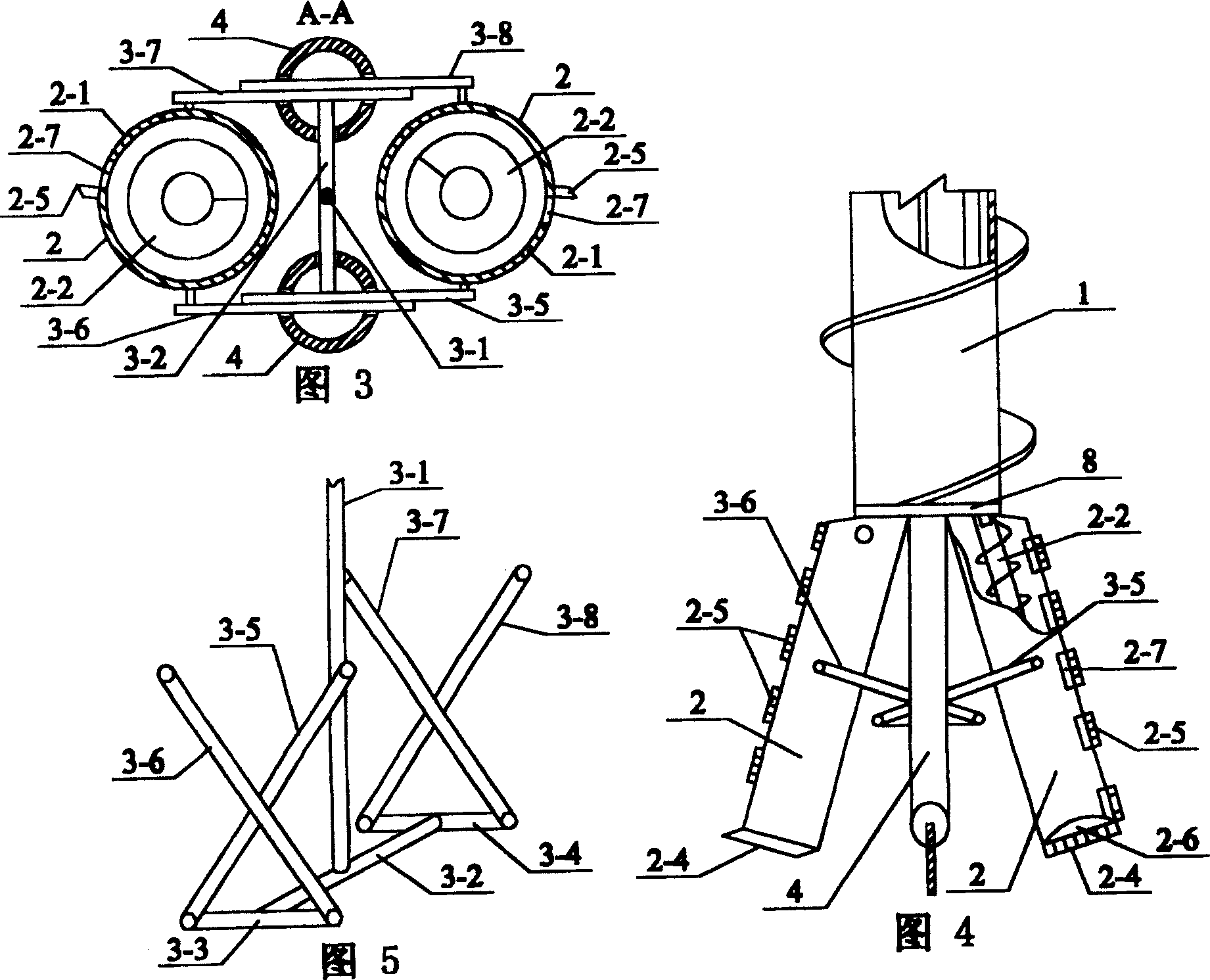

[0005] Specific embodiment one: (see Fig. 1) present embodiment is made up of motor, speed reducer, auger rod 1, pipe drill bit 2, tensioner 3, reinforcing pipe 4, tensioning pipe 5, connecting rod 6, hinge 7, method Composed of flange 8; the rotation of the motor drives the output shaft of the reducer to rotate, the output shaft of the reducer drives the rotation of the auger rod 1, the lower end of the auger rod 1 is fixed with a flange 8, and the lower end of the flange 8 is fixed with two hinges 7, two The hinge 7 is respectively hinged and fixed to the upper ends of the two pipe drill bits 2, the two reinforcement pipes 4 are arranged parallel to the two pipe drill bits 2, the upper ends of the two reinforcement pipes 4 are respectively fixed on the flange 8, and the tensioner 3 is fixed on the two The middle and lower part between the two reinforcement pipes 4, the tension pipe 5 and the two connecting rods 6 are arranged in the auger rod 1 respectively. (See figure 2 ,...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 2 , Figure 6 ) The difference between this embodiment and the specific embodiment one is that the two connecting rods 6 in the auger rod 1 are replaced by a connecting pipe 9, the auger rod 1 is replaced by a thin auger rod 12, and in the thin auger rod 12 A connector 10 is added between the lower end of the lower end and the flange 8, and the connector 10 consists of a connector box 10-1, a large gear 10-2, a large gear shaft 10-3, two small gears 10-4, two small The gear shaft 10-5 is composed of; the large gear 10-2 is fixed on the large gear shaft 10-3, the large gear 10-2 is arranged in the connector box 10-1, and the two small gears 10-4 are respectively fixed on two On the pinion shaft 10-5, two small gears 10-4 are respectively fixed on both sides of the large gear 10-2 in the connector box 10-1, and the two small gears 10-4 mesh with the large gear 10-2 respectively , the upper end of the large gear shaft 10-3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com