Method for determining the position of a positioning element of an electrically-operated actuator, corresponding circuit arrangement and device

A technology for positioning components and actuators, applied in electrical components, circuits, transportation and packaging, etc., can solve problems affecting output signals, achieve low cost, continuous and reliable operation, and achieve the effect of over-temperature protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

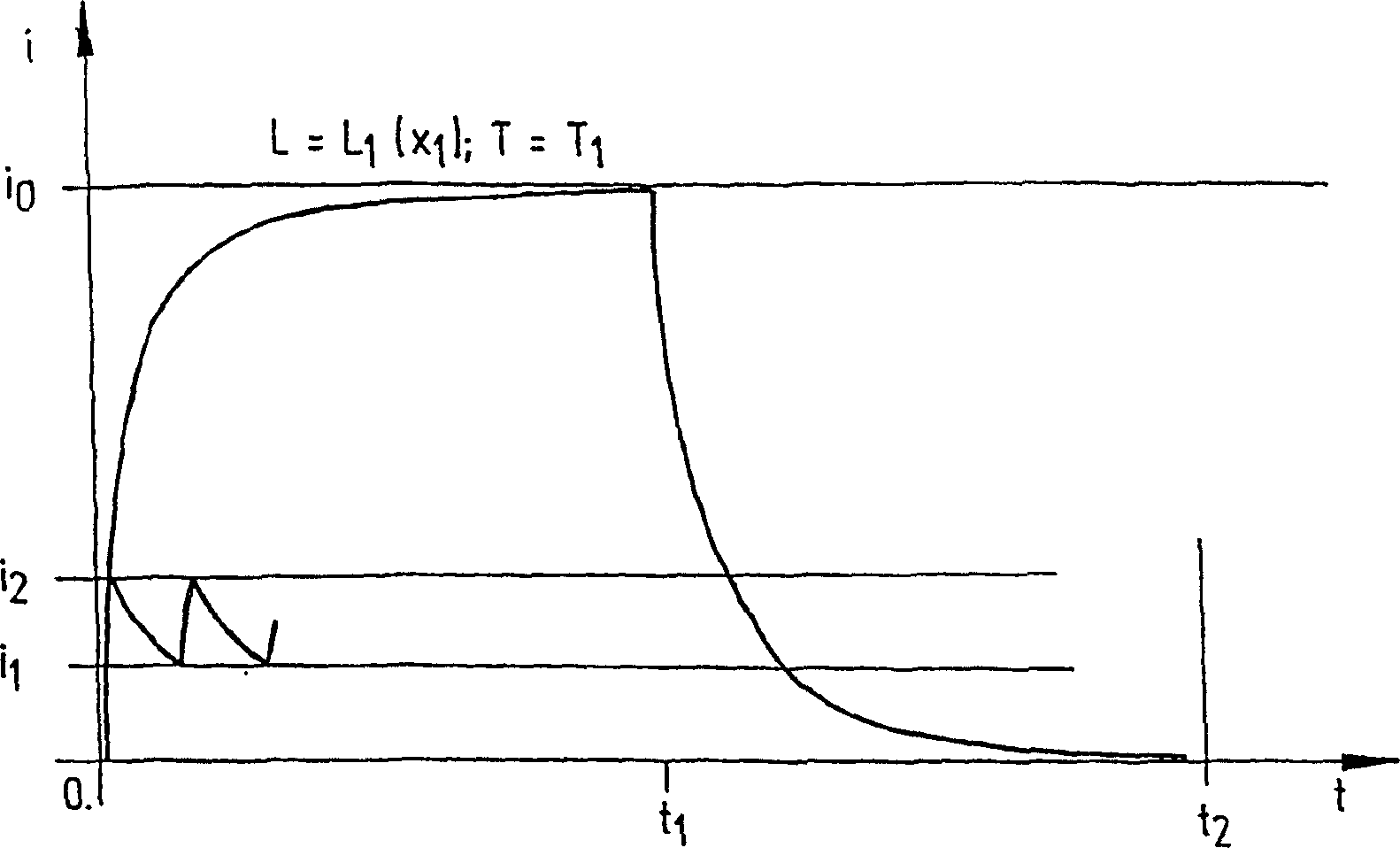

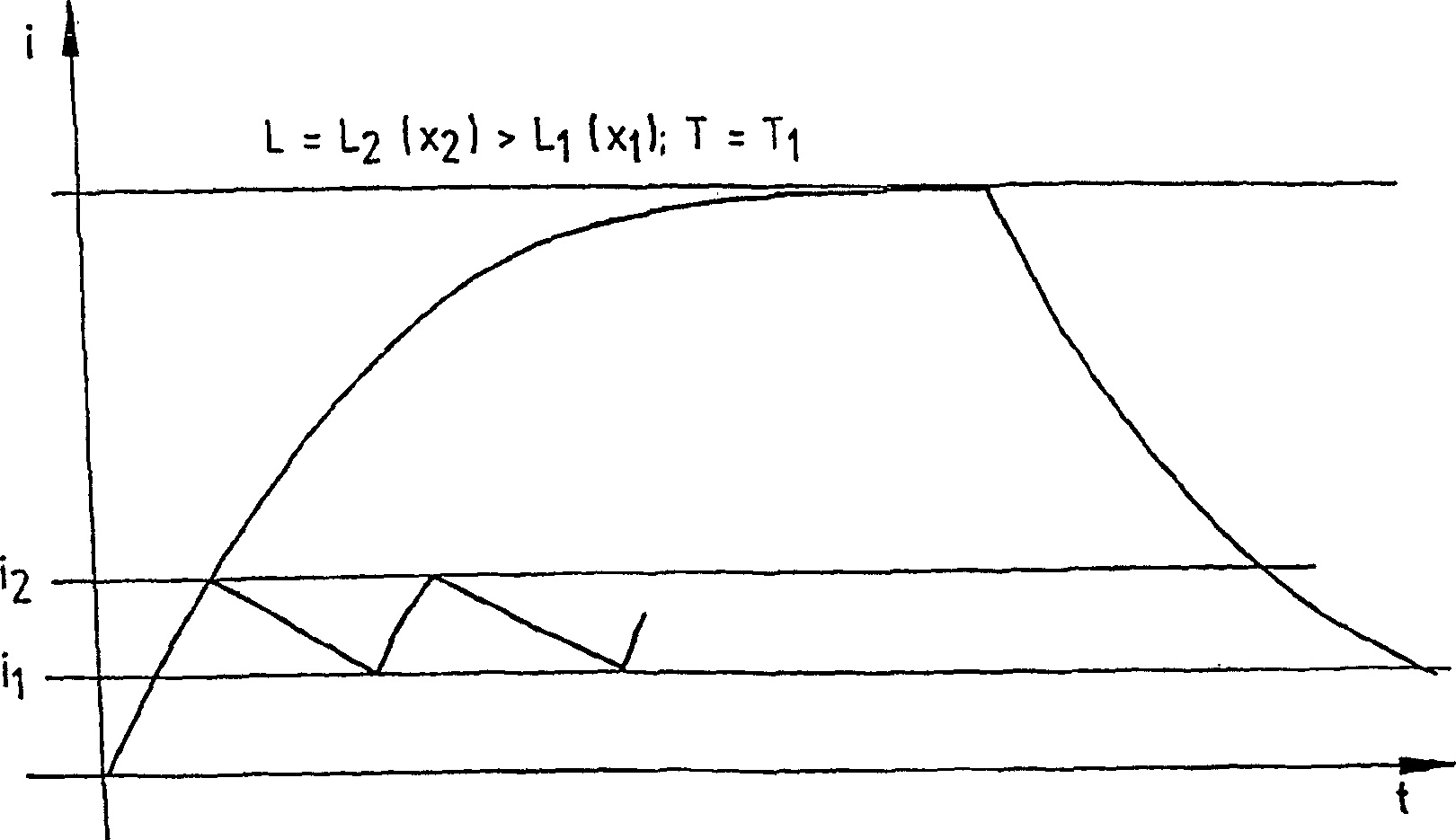

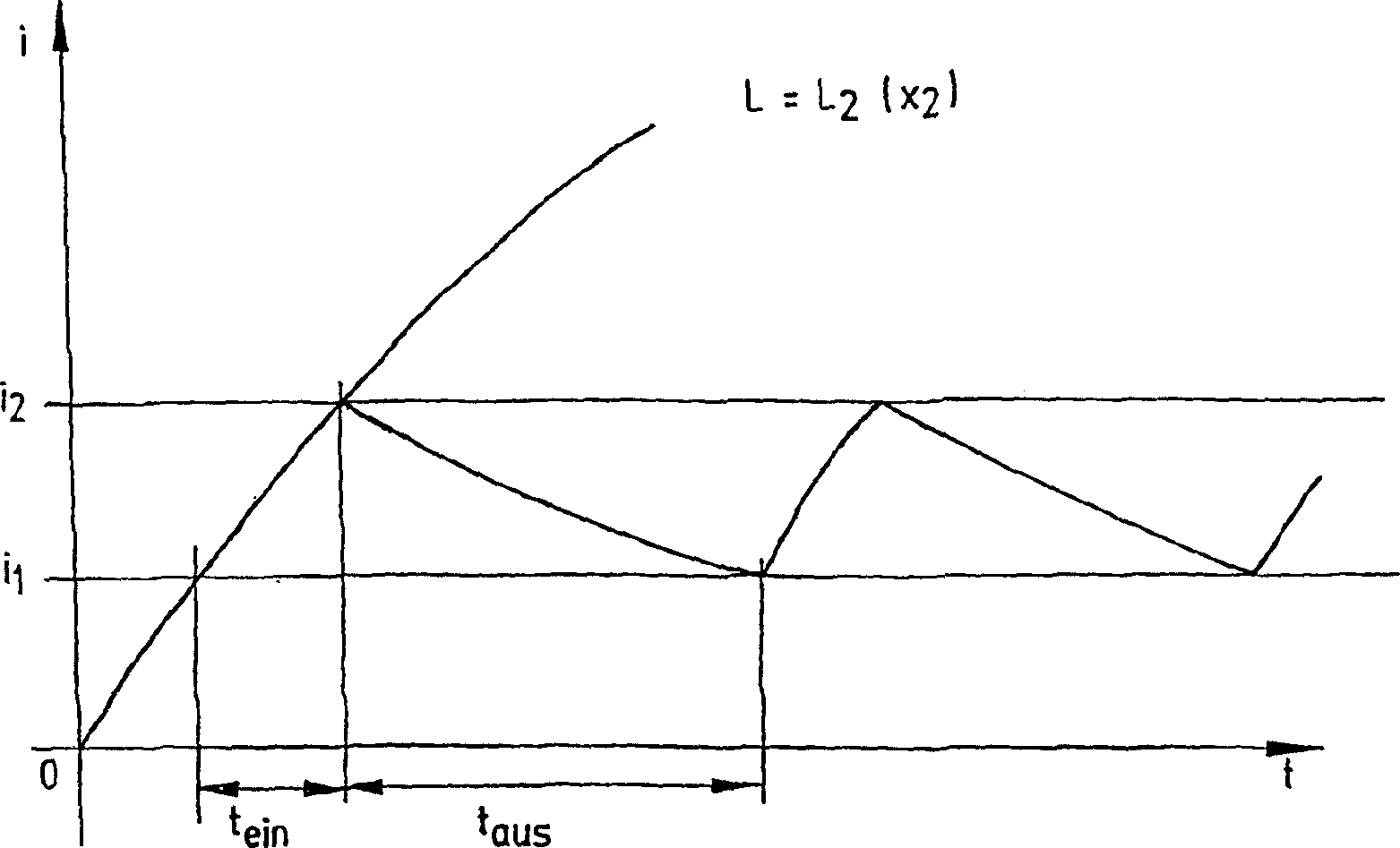

[0030] figure 1 Show device 12 of the present invention ( Figure 5 ) The variation curve of the coil current i of the winding coil 10 of an electromagnet with time t. In the opening process 01 Medium rated voltage U o Added to the electromagnet, since the ohmic resistance of the winding coil is R, the current i o The final value of i o =U o / R gives. During the shutdown process t 1 2 Medium rated voltage U oCut off from the winding coil 10 and generate an exponentially decaying current i(t). The corresponding time constant τ is determined by the ratio of the coil inductance L to the ohmic resistance R of the winding coil. for figure 1 As shown in the i(t) curve, the equipment temperature T is at the first value T 1 .

[0031] according to Figure 5 The embodiment of the device 12 according to the invention is shown as a hydraulic proportional valve 42 , the electromagnet has an axially movable armature 14 , the inductance L of the electromagnet depends on the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com