Internal combustion engine

A technology for internal combustion engines and fuels, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as valve flow dynamics or undesired changes in closing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

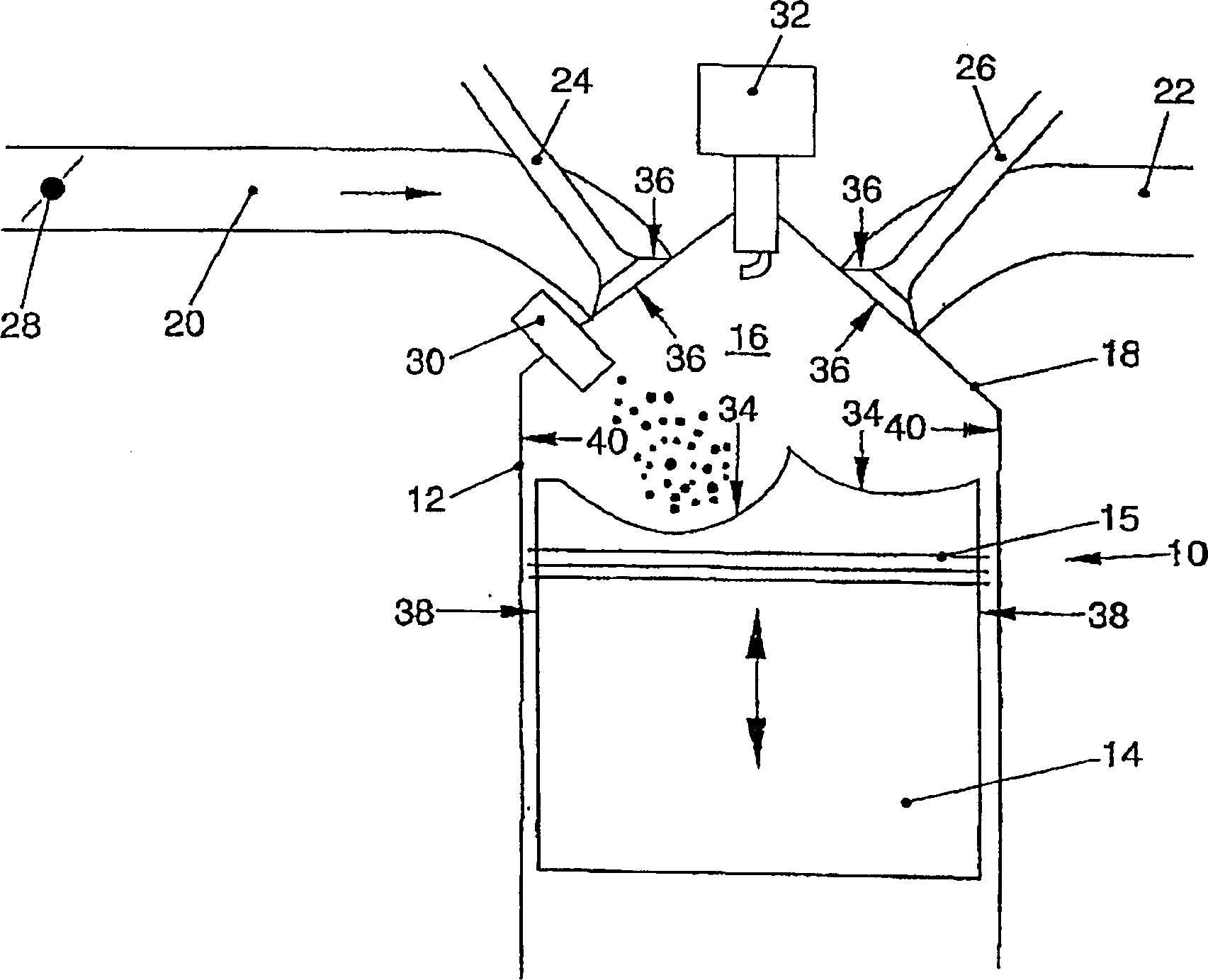

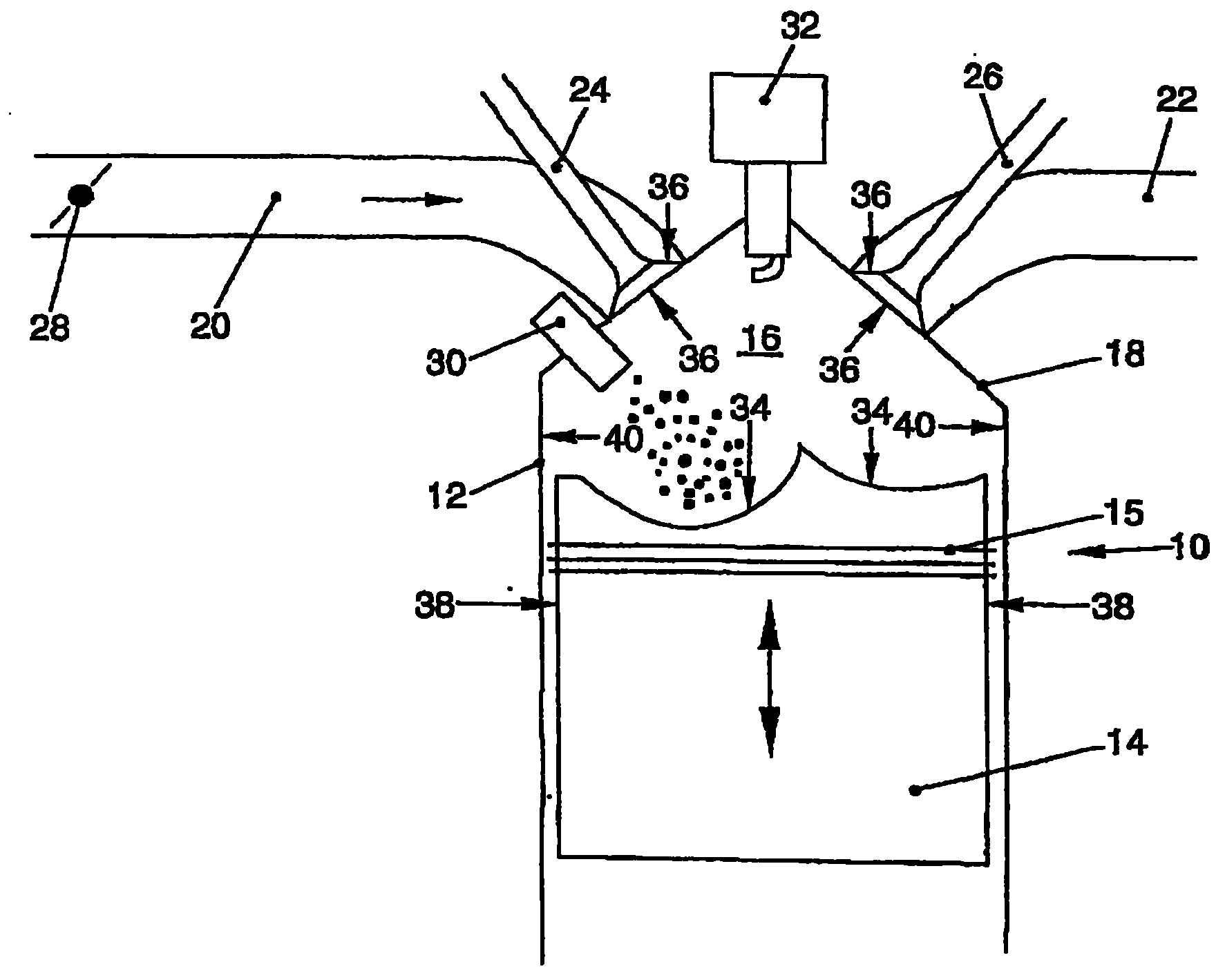

[0015] Only one cylinder 12 is shown in the internal combustion engine, generally designated 10 . It goes without saying that internal combustion engine 10 can also have a plurality of cylinders 12 arranged in different ways. A piston 14 is arranged axially movable in the cylinder 12 , the longitudinal movement of which is converted into a rotational movement of a crankshaft (not shown). A combustion chamber 16 is delimited in the interior of the cylinder 12 by the piston 14 , which is sealed by a piston ring 15 . One side of a cylinder head 18 of the cylinder 12 communicates with an intake pipe 20 through which air is supplied to the combustion chamber 16 , and the other side communicates with an exhaust pipe 22 through which exhaust gas is discharged. The intake manifold 20 and exhaust manifold 22 are opened and closed via intake valves 24 or exhaust valves 26 , which are asynchronously actuated by a camshaft (not shown). It goes without saying that there can also be sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com