Stress sheath demage predicting method

A prediction method and stress technology, applied in the direction of measuring force, measuring device, using stable tension/pressure to test the strength of materials, etc., can solve problems such as inability to predict casing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1: Casing anti-internal pressure strength:

[0099] Figure 4 The middle series 1 is the stress-strain relationship of the casing against internal pressure when the pressure difference between the inside and outside of the casing is 0, and the elastic-plastic strength of the casing P p ′ is 66MPa. When the external load (internal pressure) reaches this value, it begins to enter the elastic-plastic stage, and its change law is no longer a linear relationship, and its strain change range is only 0.1 mm to 0.2 mm. Instrumental monitoring of its changes is very difficult. The strength of casing against internal pressure increases more and more slowly, but the value is still relatively large, and the ability of casing to resist internal pressure is still relatively large, which is not the main type of casing damage in oilfields. Series 2, 3, and 4 are the situations when the internal pressure is 10, 20, and 30 MPa. It can be seen that the internal pressure resis...

Embodiment 2

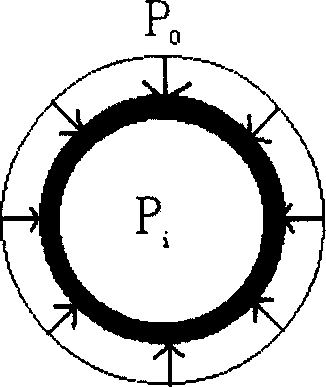

[0100] Embodiment 2: Uniform external pressure resistance strength:

[0101] Figure 5 The middle series 1 is the stress-strain relationship of the casing against uniform external pressure when the pressure difference between the inside and outside of the casing is 0, and the elastic-plastic strength of the casing P p ' is 66MPa. When the external load (external pressure) reaches this value, it begins to enter the elastic-plastic stage, and its change law is no longer a linear relationship. The strain range varies from 0.2 mm to 2.5 mm. Monitor the radial strain u of the casing r , the casing stress load P can be inverted by the formula (3) of the present invention p . The strength of casing against uniform external pressure increases more and more slowly, but the value is still relatively large. The ability of casing to resist external pressure is still relatively large, and the main types of casing damage in oilfields are not like this. Series 2, 3, and 4 are the situati...

Embodiment 3

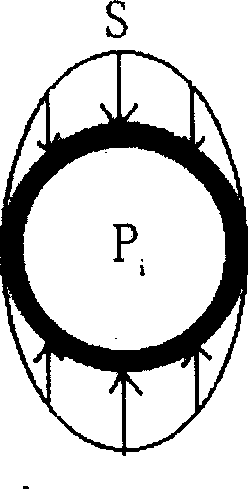

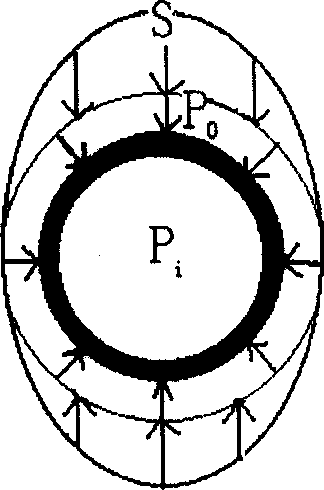

[0102] Embodiment 3: Anti-inhomogeneous external pressure strength:

[0103] Image 6 Series 1 is the stress-strain relationship of the casing against non-uniform external pressure when the pressure difference between the inside and outside of the casing is 0. The elastic-plastic strength of the casing is 5.6MPa, which is less than 10% of the uniform value. When a value begins to enter the elastic-plastic stage, its change law is no longer a linear relationship, the load resistance strength drops rapidly, and its strain range varies from 0.3 mm to 15 mm. The radial strain of the casing is monitored with a casing caliper measuring instrument u r , the casing stress load P can be inverted by the formula (3) of the present invention p . This type of casing damage is the most harmful. Series 2, 3, and 4 are the situations when the internal pressure is 10, 20, and 30MPa, and the ability of the casing to resist non-uniform external pressure decreases with the increase of interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com