Lipophilic microparticles containing protein drug or antigen and formulation comprising same

A lipophilic, protein-based technology, applied in the field of lipophilic substance-coated particles, can solve problems such as the instability of liposome particle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

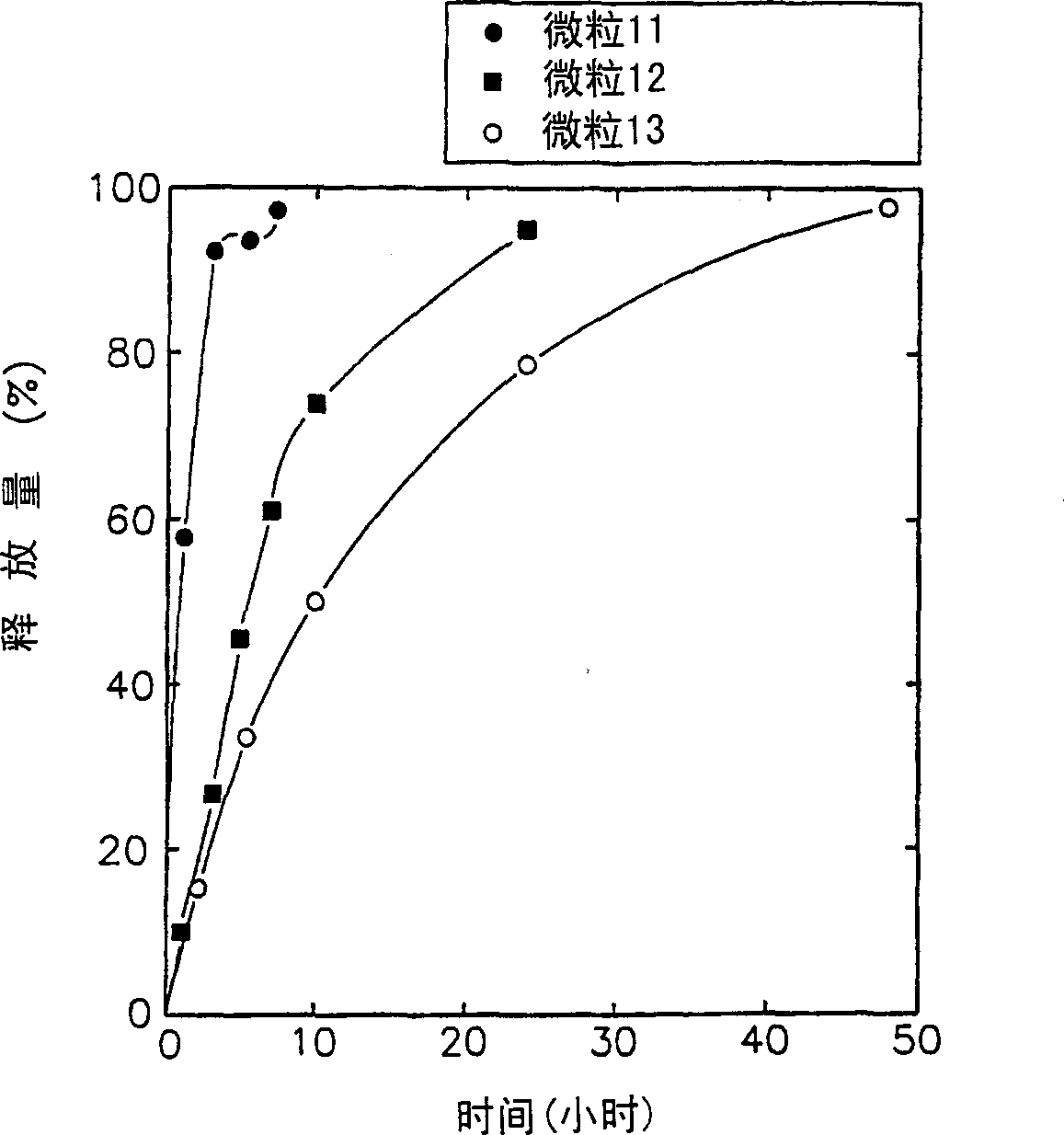

Examples

Embodiment 1

[0038] Lecithin was added to 10 mM phosphate buffered saline (PBS) at a concentration of 2% (w / v) and fully hydrated. Recombinant hepatitis B surface antigen (HBsAg, LG Chemical Ltd.) was added thereto to make the concentration 0.5 mg / ml, and then the resulting solution was sent into a spray dryer (Buchi 191), solid particles (particle 1) were obtained. In this step, the inflow air temperature was 70°C and the outflow air temperature was 50°C. The particles thus obtained have a particle size between 0.1-5 μm. Example 2: Preparation of lipophilic microparticles

Embodiment 2

[0038] Lecithin was added to 10 mM phosphate buffered saline (PBS) at a concentration of 2% (w / v) and fully hydrated. Recombinant hepatitis B surface antigen (HBsAg, LG Chemical Ltd.) was added thereto to make the concentration 0.5 mg / ml, and then the resulting solution was sent into a spray dryer (Buchi 191), solid particles (particle 1) were obtained. In this step, the inflow air temperature was 70°C and the outflow air temperature was 50°C. The particles thus obtained have a particle size between 0.1-5 μm. Example 2: Preparation of lipophilic microparticles

[0039] Recombinant HBsAg was dissolved in 10 mM PBS to a concentration of 0.5 mg / ml, and then carboxymethylcellulose was added thereto to a concentration of 3% (w / v). The resulting solution was fed into a spray dryer (Buchi 191) at a low flow rate of 0.55 ml / min to obtain primary granules. In this step, the inflow air temperature was 70°C and the outflow air temperature was 50°C.

[0040] An ethanol solution conta...

Embodiment 3

[0041] Carboxymethylcellulose was dissolved in 10 mM PBS to make the concentration 3% (w / v). To this was added lecithin to a concentration of 2% (w / v) and fully hydrated. Then, recombinant HBsAg was added thereto to make the concentration 0.5 mg / ml. The resulting solution was fed into a spray drier (Buchi 191) at a flow rate of 0.55 ml / min to obtain solid microparticles (microparticle 3). In this step, the inflow air temperature was 70°C and the outflow air temperature was 50°C. The particle size thus obtained is between 0.1-5 μm. Examples 4-9: Preparation of lipophilic microparticles

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com