Method and device for coating with paste

A coating device and paste technology, which are applied to the device, spray device, coating and other directions for coating liquid on the surface, can solve the problem that the coating position accuracy and coating area accuracy cannot be obtained, and it is not easy to control the coating with high precision. The coating amount and the large variation range of the coating amount can improve the coating efficiency, improve the coating shape accuracy, and improve the coating position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiments of the present invention are shown below, and its features are further described in detail.

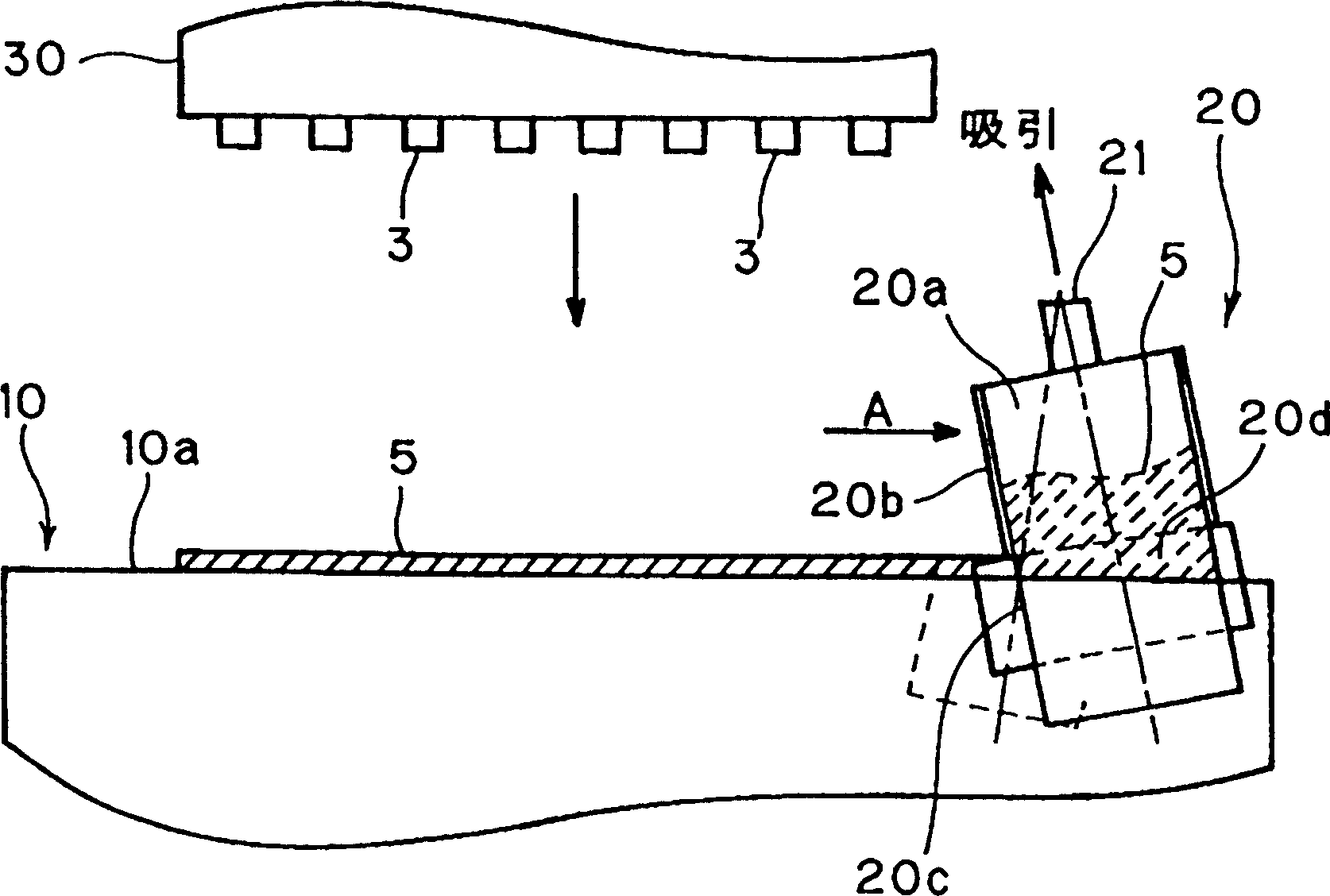

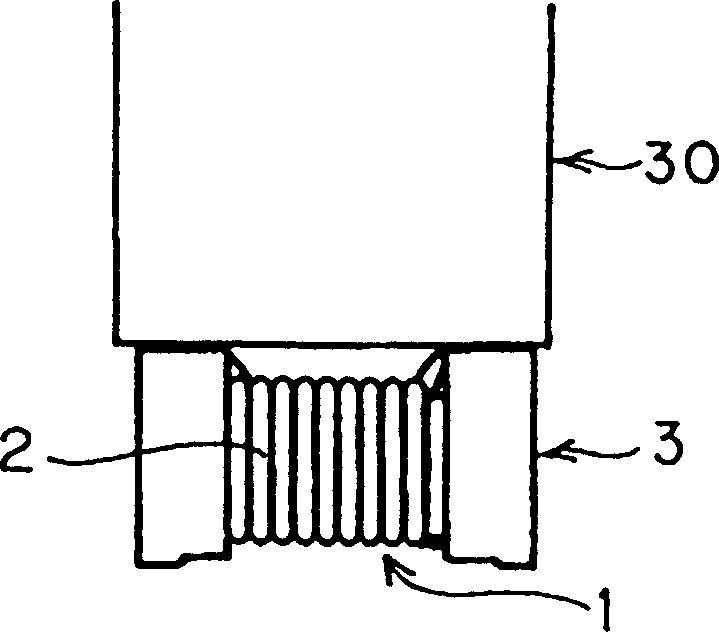

[0033] Such as Figure 5 As shown, in the case of manufacturing a coil component having a structure in which a magnetic core 3 made of ferrite with a metal wire 2 wound on a winding core 1 and a ferrite base 4 are bonded by an adhesive 5, the The case where the adhesive 5 for bonding the magnetic core 3 and the ferrite 4 is applied to the magnetic core 3 will be described as an example.

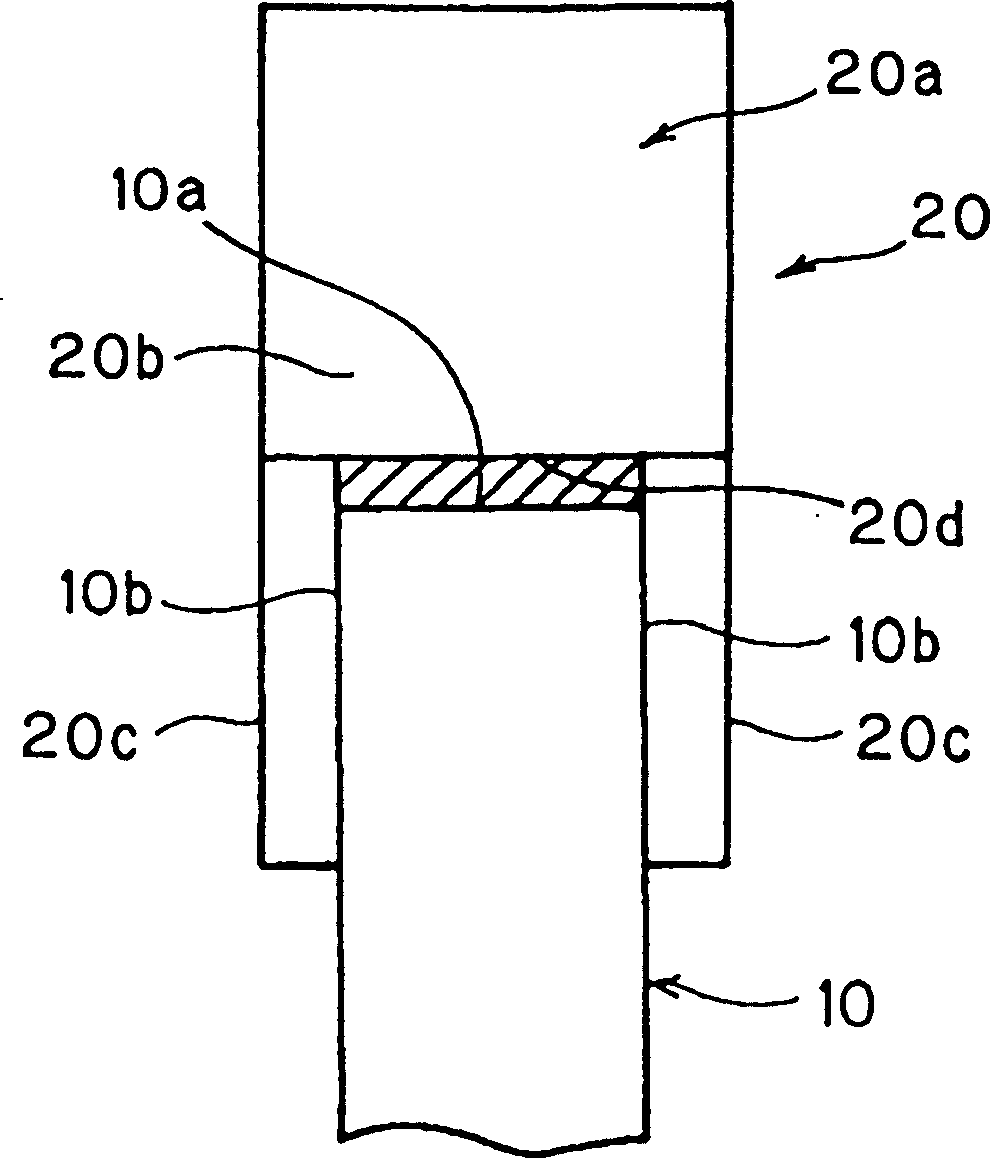

[0034] figure 1 It is a front cross-sectional view of main parts showing a paste application device for carrying out the paste application method of the present invention. figure 2 It is a side view showing the locking relationship between the paste application frame and the paste supply device. image 3 It is a side view showing the state where the coating object (magnetic core) is held by the holding device.

[0035] Such as figure 1 , figure 2 as well as image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com