Printing film coating equipment convenient to adjust

A technology of lamination and equipment, applied in the field of lamination equipment, can solve the problems of affecting work efficiency, inability to adjust the thickness of the lamination roll, uneven viscosity of the adhesive on the surface of the lamination drum, etc., to achieve uniform adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

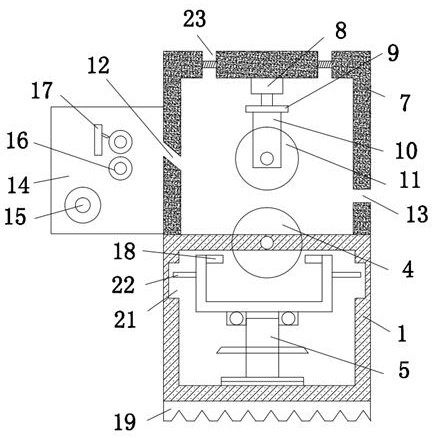

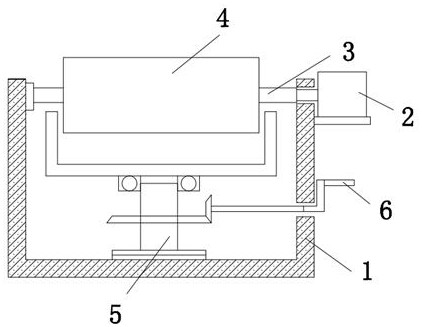

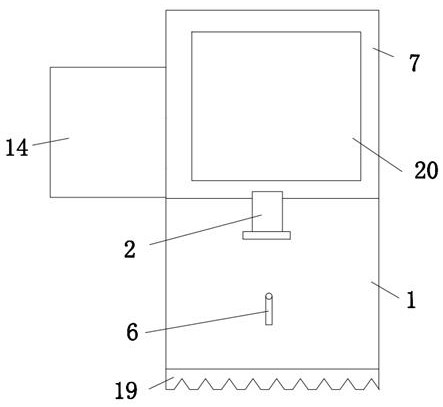

[0038] see Figure 1-Figure 3 , a printing and laminating equipment that is easy to adjust, comprising an outer box 1, a motor 2 is fixedly connected to the front of the outer box 1, and the output end of the rotating motor 2 penetrates the outer box 1 and is fixedly connected to a rotating shaft 3, and the rotating shaft The back side of 3 is rotationally connected with the rear inner wall of the outer box 1 through the first ball bearing, and the outer surface of the rotating shaft 3 is fixedly connected with the coating drum 4, and the front inner wall and the rear inner wall of the outer box 1 are vertically provided with A chute 21, the inner bottom side of the outer box 1 is fixedly connected with a support mechanism 5, the front of the outer box 1 is provided with a round hole, and the round hole is located at the lower end of the motor 2, and the handle 6 is placed inside the round hole , the top of the outer box 1 is fixedly connected with a working box 7, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com