Cooling pipe for cigarette, preparation method of cooling pipe and cigarette with cooling pipe

A technology for cooling tubes and cigarettes, which is applied in the field of cooling low-temperature cigarettes to achieve good safety, reduce biological safety risks, and increase the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

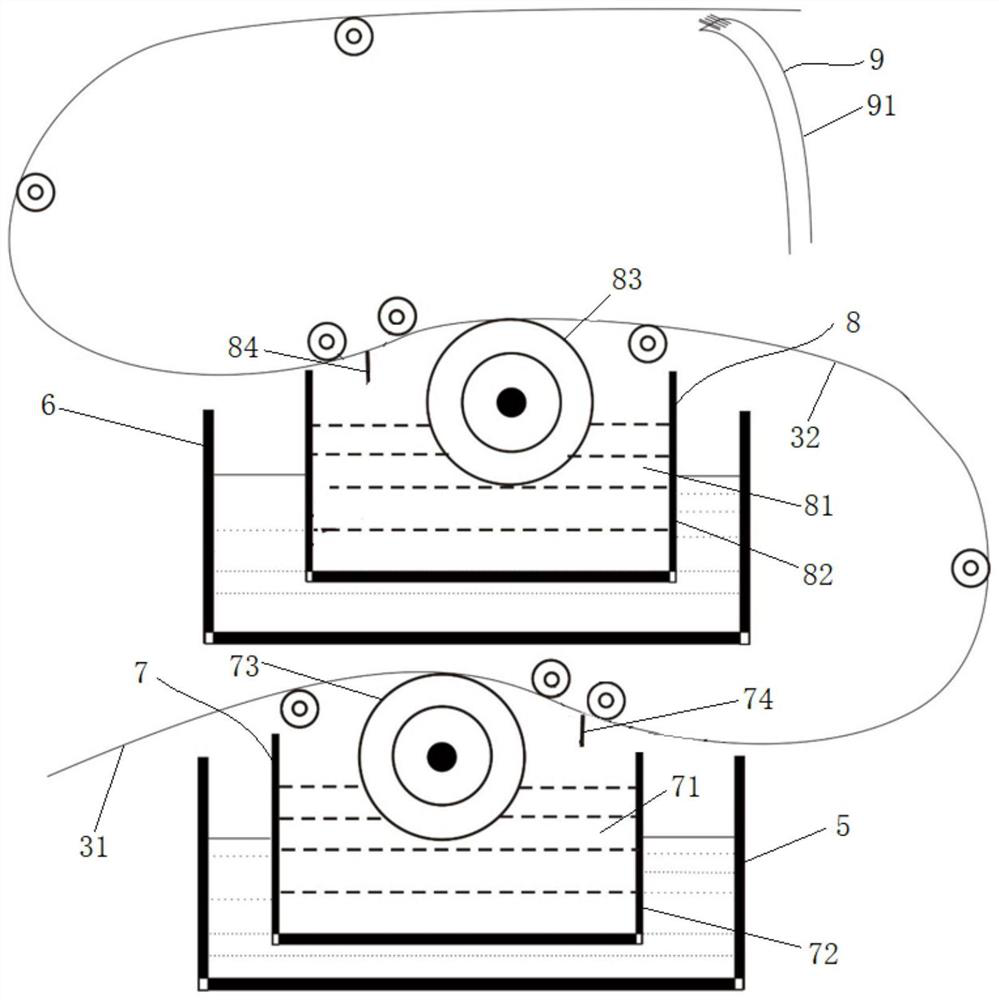

[0063] Such as figure 2 Shown, the preparation method of cigarette cooling tube of the present invention comprises the following steps:

[0064] (1) Obtain the functional carrier 3, use the functional material loading device to load the cooling layer 4 on the first side of the functional carrier 3, and load the moisture-proof layer 2 on the second side of the functional carrier 3.

[0065] (2) Obtain the shell layer so that the functional carrier 3 is connected to the inner wall of the shell layer through the moisture-proof layer 2, and roll the shell layer, the moisture-proof layer 2, the functional carrier 3 and the cooling layer 4 together to form a cooling tube for cigarettes.

[0066] In a specific embodiment, the shell layer and the functional carrier 3 loaded with the moisture-proof layer 2 and the cooling layer 4 are drawn together at the same position on a transmission rod with a certain diameter for rolling to form a cooling tube for cigarettes. Wherein, the coolin...

Embodiment 1

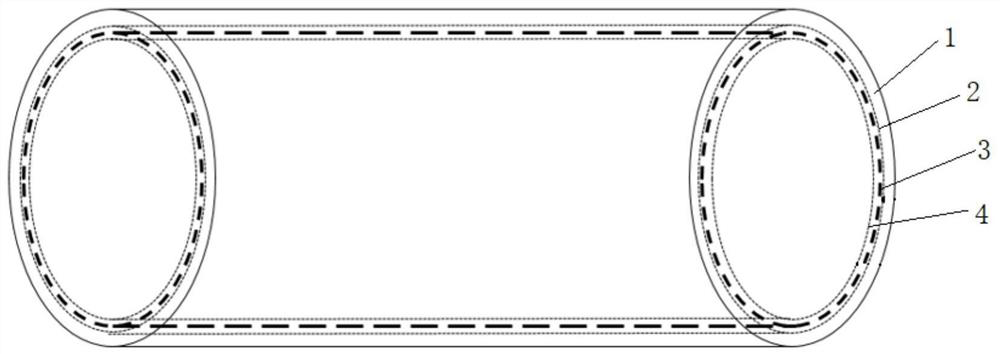

[0090] Such as figure 1 As shown, the cigarette cooling tube provided in this embodiment is a hollow cylindrical tubular structure. The cooling pipe for cigarettes includes a casing 1 , a moisture-proof layer 2 , a functional carrier 3 and a cooling layer 4 in sequence from outside to inside. The moisture-proof layer 2 and the cooling layer 4 are respectively coated on both sides of the functional carrier 3 , and the housing 1 is connected to the moisture-proof layer 2 through an adhesive, and then connected to the functional carrier 3 .

[0091] Further, the functional carrier 3 is the first fiber paper.

[0092] Further, the casing 1 is the second fiber paper.

[0093] Further, the moisture-proof layer 2 is carnauba wax.

[0094] Further, the cooling layer 4 is polyethylene glycol.

[0095] Further, the load of carnauba wax is 18-20wt%. The melting point of carnauba wax is 82-85 degrees Celsius.

[0096] Further, the molecular weight of polyethylene glycol is 6000. Th...

Embodiment 2

[0098] Such as figure 1 As shown, the cigarette cooling tube provided in this embodiment is a hollow cylindrical tubular structure. The cooling pipe for cigarettes includes a casing 1 , a moisture-proof layer 2 , a functional carrier 3 and a cooling layer 4 in sequence from outside to inside. The moisture-proof layer 2 and the cooling layer 4 are respectively coated on both sides of the functional carrier 3 , and the housing 1 is connected to the moisture-proof layer 2 through an adhesive, and then connected to the functional carrier 3 .

[0099] Further, the functional carrier 3 is the first fiber paper.

[0100] Further, the casing 1 is the second fiber paper.

[0101] Further, the moisture-proof layer 2 is shellac.

[0102] Further, the cooling layer 4 is polylactic acid.

[0103] Further, the load of the moisture-proof layer 2 is 22-25wt%. The melting point of the moisture-proof layer 2 is 75-80 degrees Celsius.

[0104] Further, the molecular weight of polylactic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com