Sealing ring type filling device

A sealing ring type, stuffing box technology, applied in sealing, engine sealing, packaging, etc., can solve the problems of shortened life, failure, excessive wear of seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

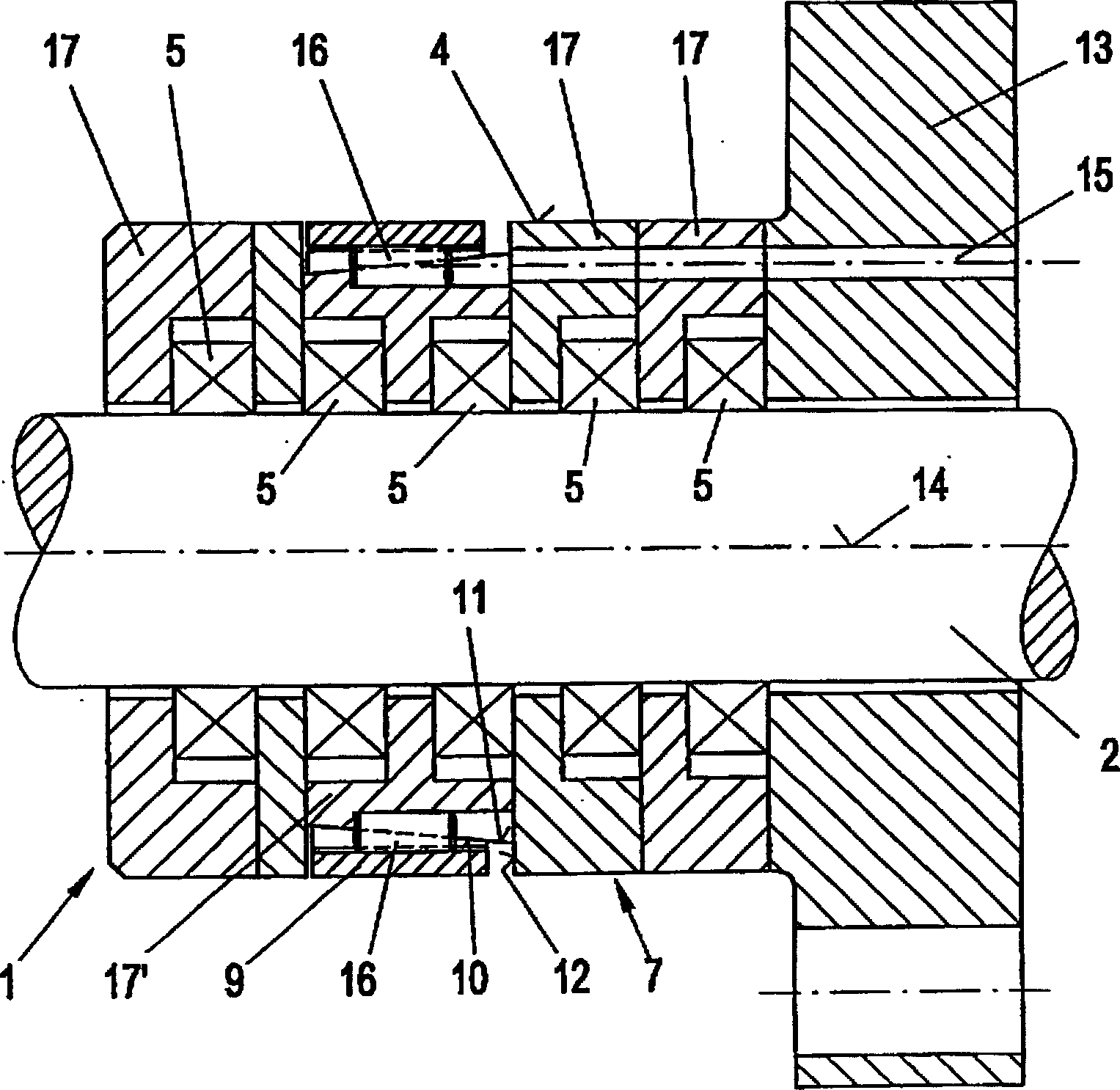

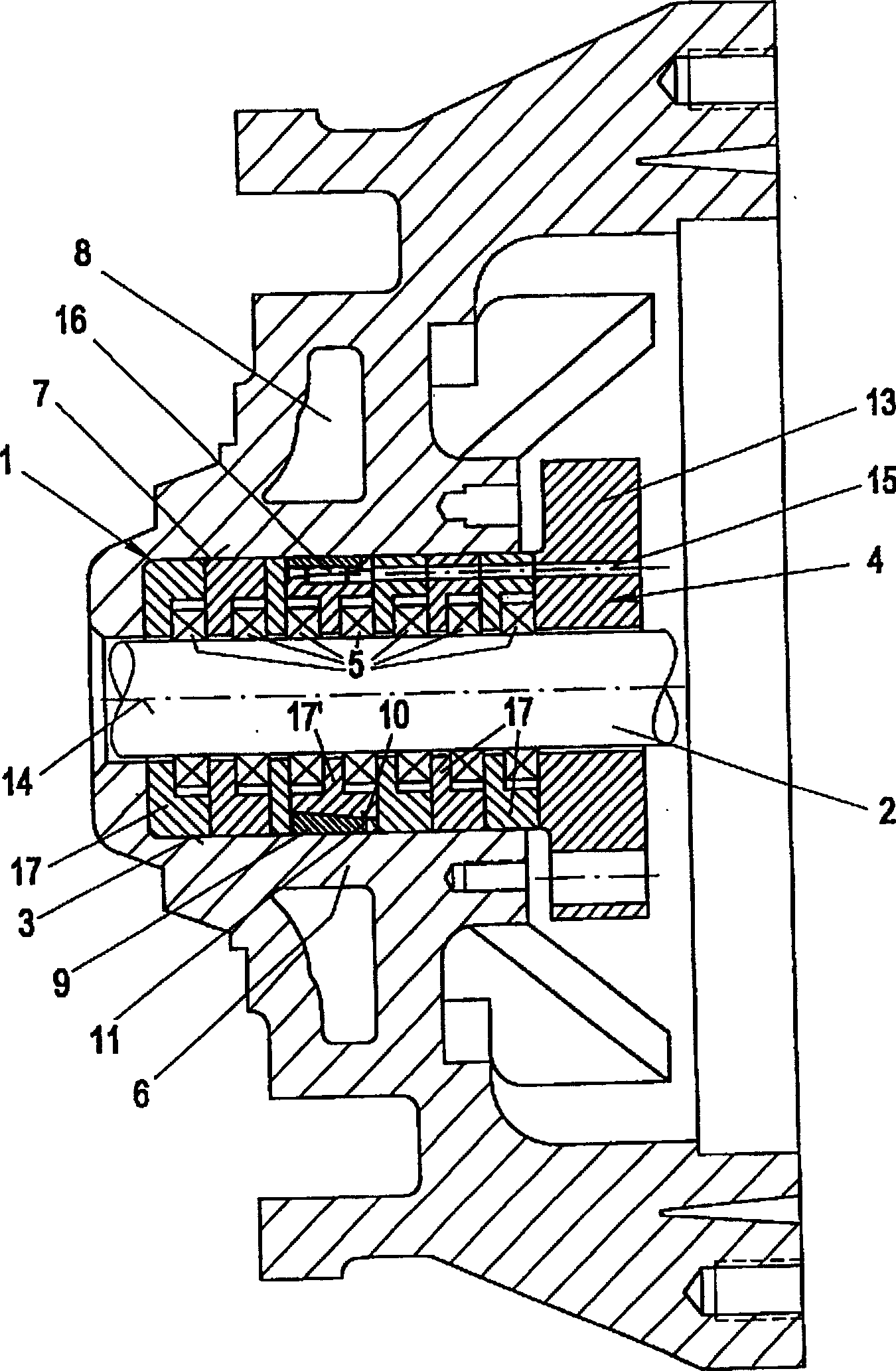

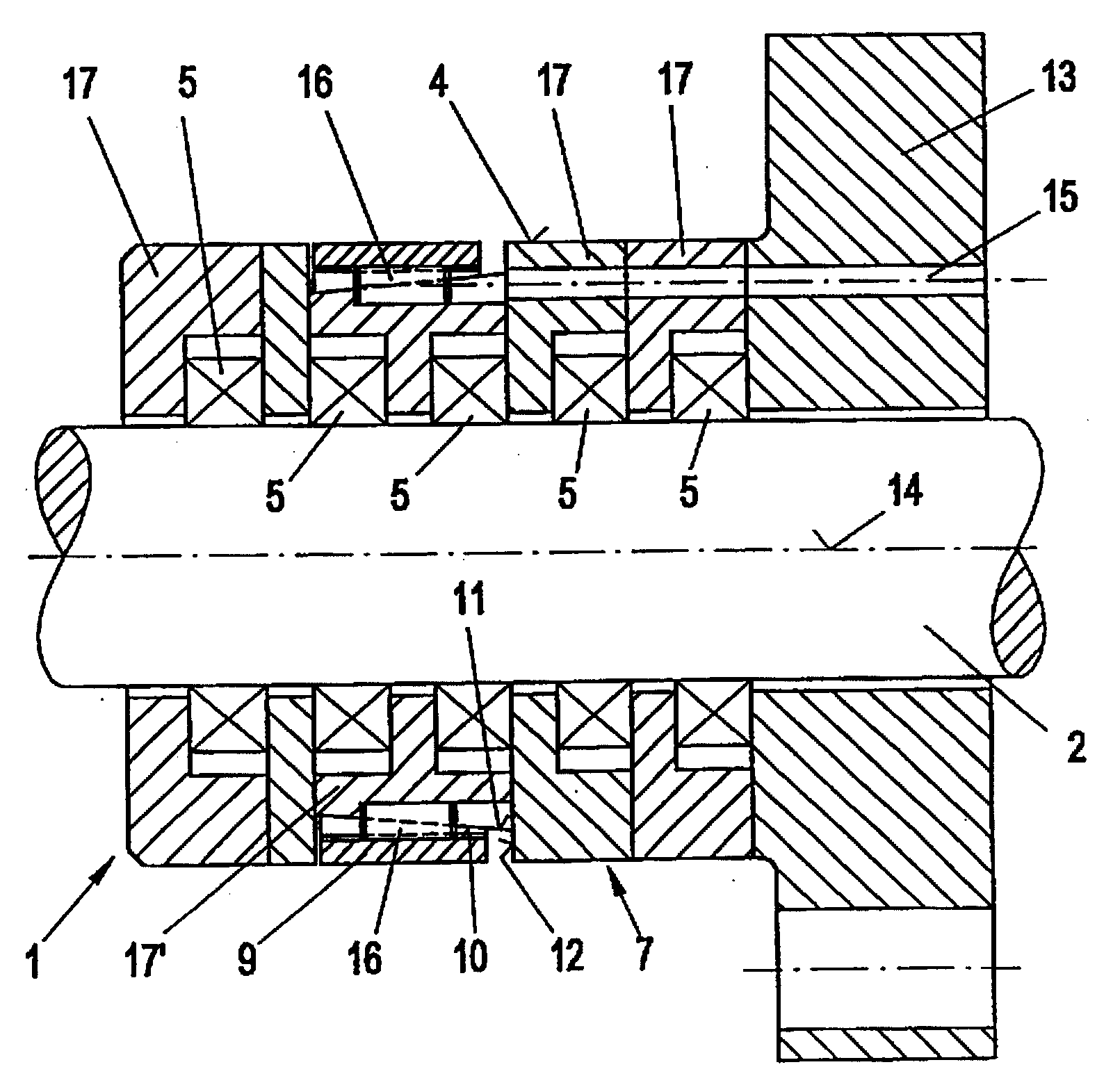

[0013] The following will describe as much as possible figure 1 and figure 2 , wherein in all cases identical or functionally similar components are given the same designation in both figures.

[0014] The sealing ring packing device shown in the two figures is used for sealing the passage of the reciprocating piston rod 2 of a not further shown piston compressor, wherein the piston compressor is used, for example, as a process compressor for various gases . Wherein the stuffing device 1 has a through hole 3 that can be inserted into a stuffing box (see figure 2 ) packing housing 4, a plurality of substantially annular sliding seals 5 are arranged in the packing housing 4, and each sliding seal 5 presses against the sealed moving member (here, the piston rod 2). The type and specific configuration of the sliding seal 5 is no longer important here, it is only important that the frictional heat generated by its friction against the piston rod 2 has to be conducted away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com