Rotary drum type sterilized filling device

A technology of filling device and drum, which is applied in liquid filling, packaging, bottling machines, etc., and can solve problems such as working environment pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description will be made with reference to the embodiments of the present invention.

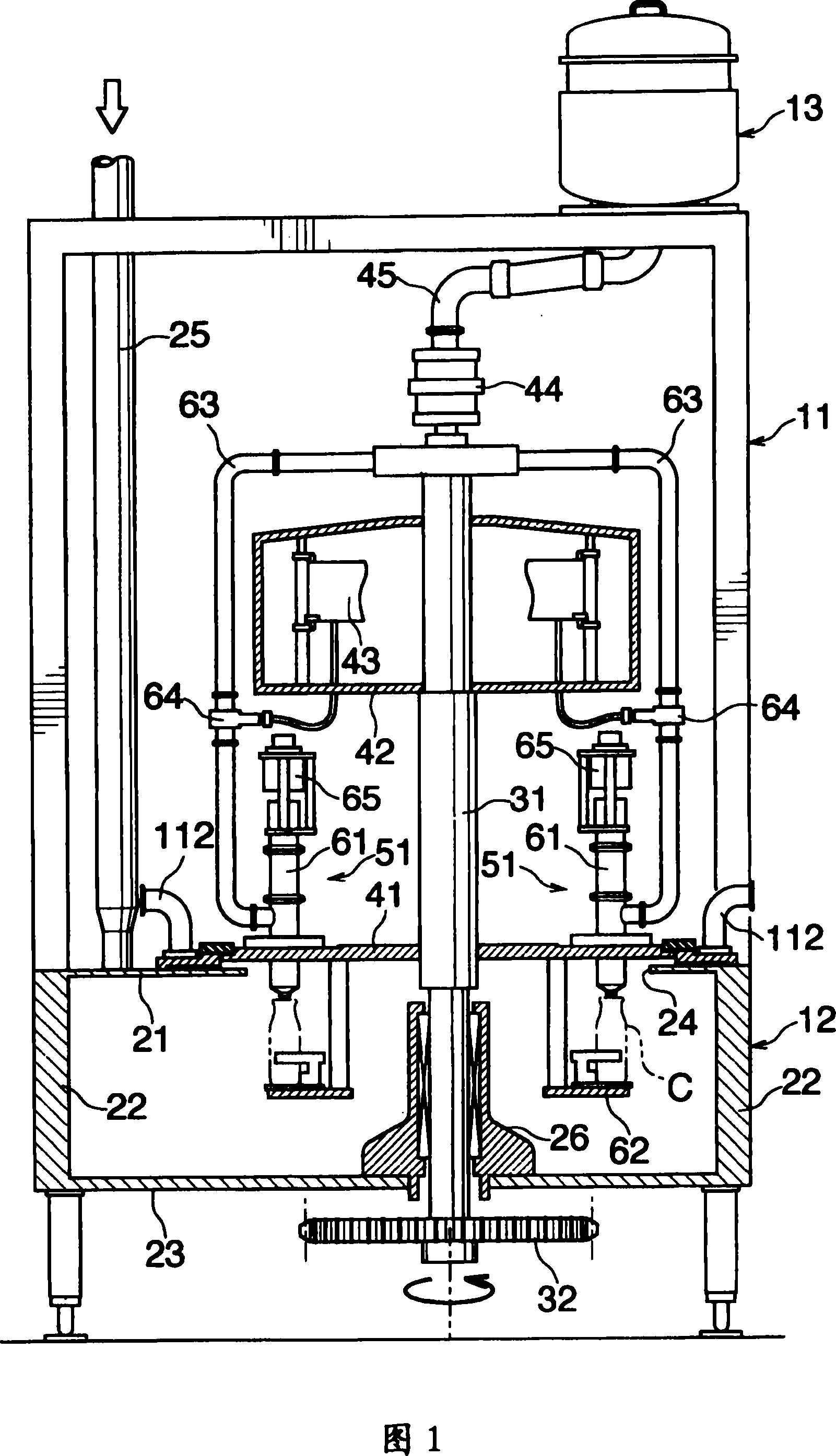

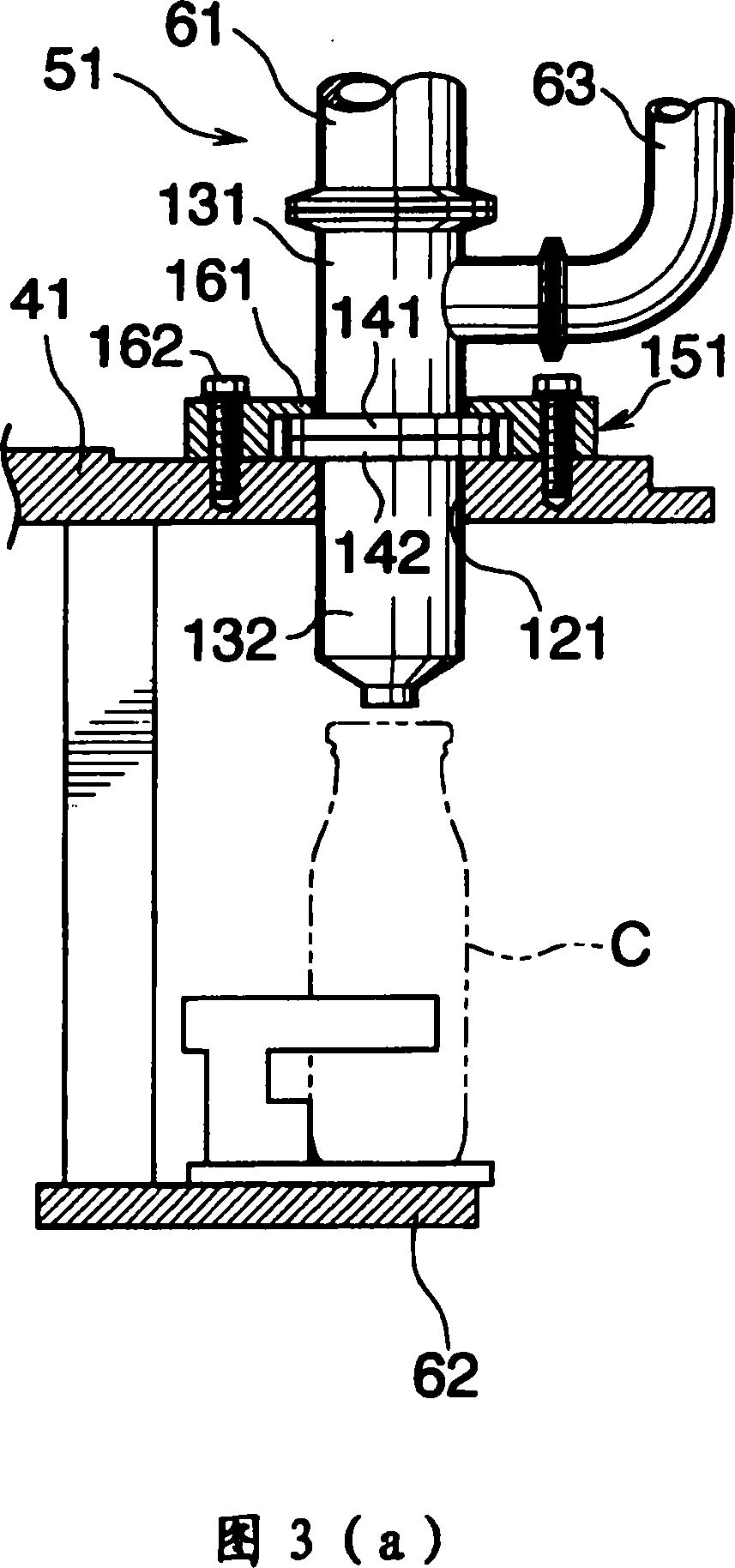

[0025] The filling device has a device main body 11 with a skeleton structure, a sterile chamber 12 arranged at the bottom of the device main body 11 and a filling liquid tank 13 supported on the top of the device main body 11 .

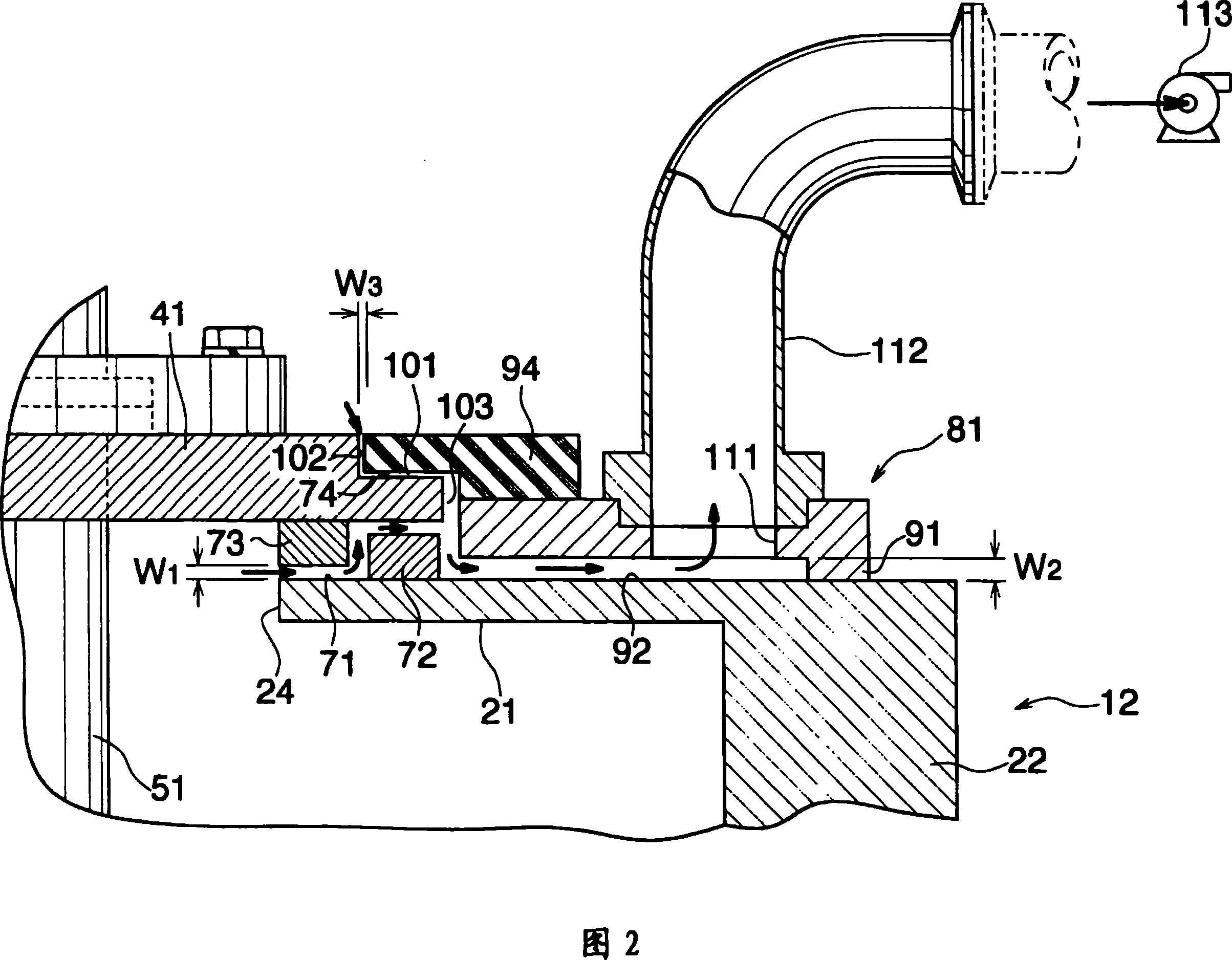

[0026] The sterile room 12 is viewed as a square box from above, and has a top wall 21 , a side wall 22 and a bottom wall 23 . A circular opening 24 is provided at the center of the top wall 21 . A sterile air supply pipe 25 is connected to the side of the opening 24 . A bearing 26 is provided on the bottom wall 23 , and the bearing 26 is concentric with the center of the opening 24 .

[0027] The bearing 26 is supported by the vertical rotation shaft 31 . The rotation shaft 31 longitudinally cuts off the sterile chamber 12 , and its upper end reaches near the top of the device main body 11 . A driven gear 32 that meshes with a not-shown dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com