Glass spinneret and fabricating method

A spinneret and glass technology, applied in the direction of spinneret assemblies, textiles and papermaking, etc., can solve problems such as unfavorable spinning speed, affecting spinning forming quality, melt fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

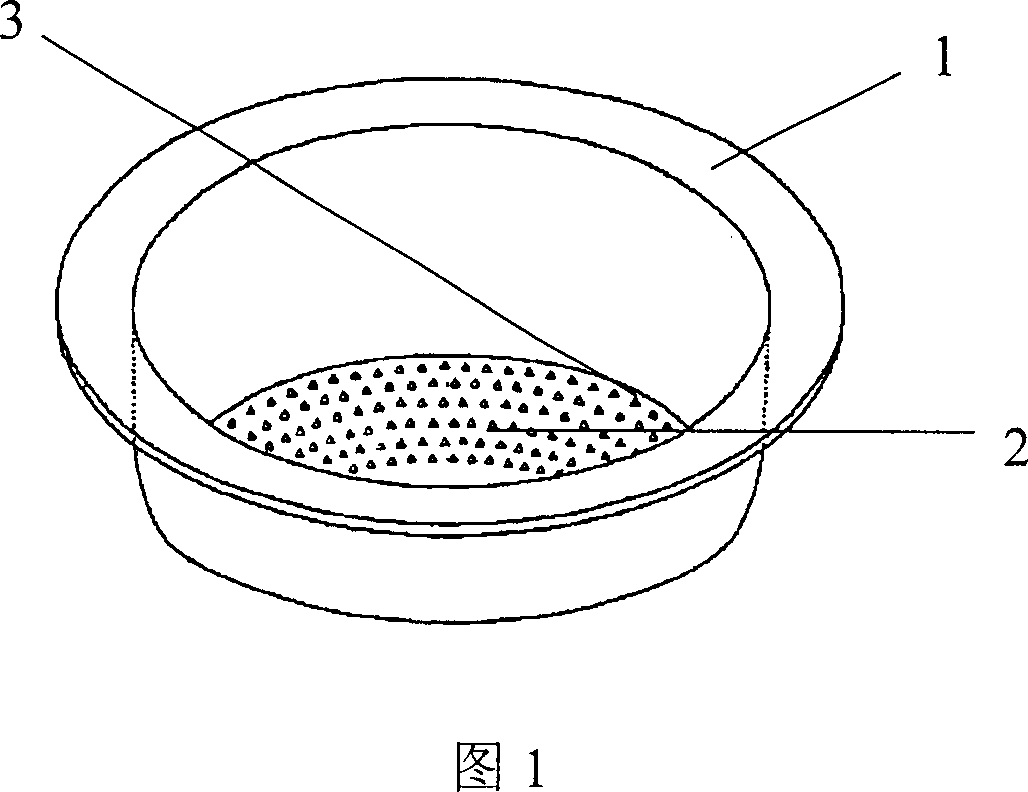

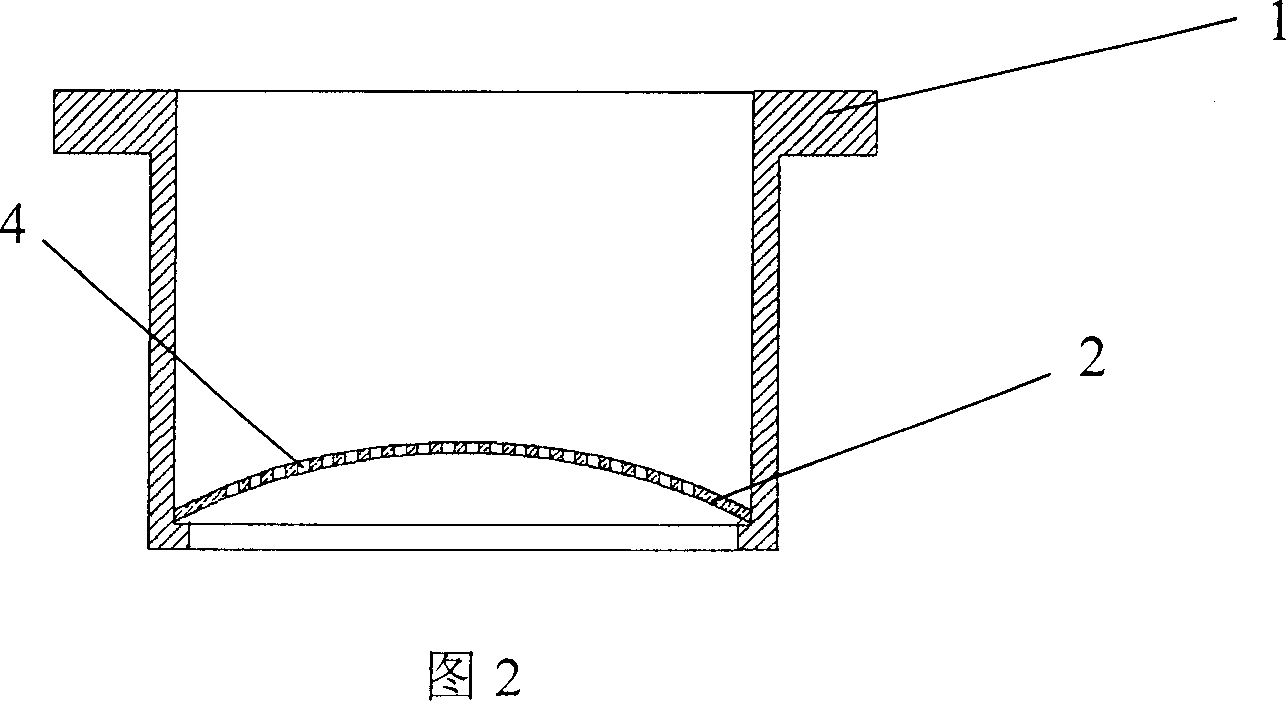

Embodiment 1

[0012] The glass spinneret is composed of a hat-shaped metal shell 1 and a glass spinneret 2 with spinneret holes embedded in the bottom, and the metal shell 1 and the glass spinneret 2 are sealed and fixed with an organic adhesive 3 . There are spinneret holes 4 on the glass spinneret 2, the number of spinneret holes is 3000 holes, the hole diameter is 65 microns, the hole distance is 330-450 microns, and the hole diameters are distributed in the circumference area not larger than the diameter of 22 mm. In order to meet the working pressure of chemical fiber spinning, and according to the requirement of the length-to-diameter ratio of the spinneret hole, the glass spinneret 2 is made into a spherical glass sheet with equal thickness. The surface is a concave spherical surface, the radius of curvature of the concave spherical surface is 90 mm, the curvature radius of the convex spherical surface is 91.4 mm, and the thickness of the glass spinneret is 2 mm. The glass spinneret ...

Embodiment 2

[0013] Embodiment 2 Its main parameters are listed in Table 1, except that the cross section of the embedded metal wire is rectangular, thereby forming a spinneret hole with a rectangular cross section, and the rest are the same as in Embodiment 1.

[0014] spinneret

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com