Method for processing clay pot with fish head capable of being preserved under constant temperature

A processing method and fish head technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of inconvenience for consumers to carry and consume, limited product sales radius, difficult long-distance sales, etc., to expand the sales radius, improve the Market competitiveness and the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

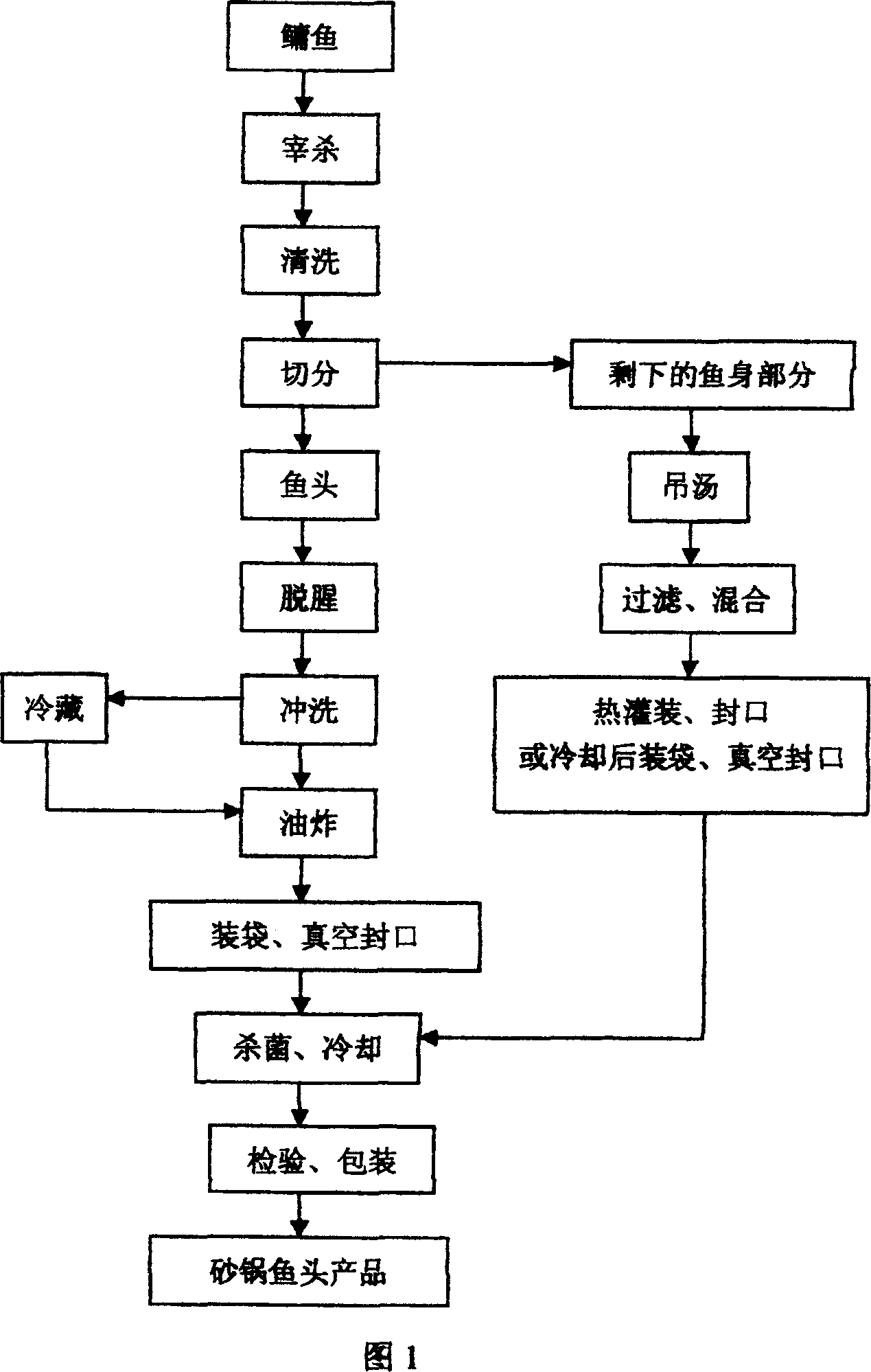

Image

Examples

Embodiment 1

[0028] Fresh bighead carp is used as raw material, and the fish weighs 3.0kg. The fish is stunned with a wooden stick and then slaughtered. Clean the scales on the surface of the fish with a stainless steel brush, carefully remove the internal organs and gills, and then use clean water to clean the remaining scales, blood stains and other debris inside and outside the fish, and remove the black film and inner ridges in the fish chamber. The blood stasis at the place was removed. Cut the cleaned fish from the front of the dorsal fin, and the fish head weighs 1.5kg. Dip the cut fish head in the deodorization solution with a salt mass concentration of 996 for deodorization treatment. The mass ratio of the fish head to the deodorization solution is 1:1.5, the deodorization time is 3.5h, and the salt solution and ambient temperature are ≤ 15°C. Take out the deodorized fish head, and wash off the mucus and blood stains on the surface with running water. After draining, put it in ...

Embodiment 2

[0032] Fresh bighead carp is used as raw material, the fish weighs 2.5kg, and the fish is stunned with a wooden stick before slaughtering. Clean the scales on the surface of the fish with a stainless steel brush, carefully remove the internal organs and gills, and then use clean water to clean the remaining scales, blood stains and other debris inside and outside the fish, and remove the black film and inner ridges in the fish chamber. The blood stasis that comes out is removed cleanly. The washed fish are graded from the back of the dorsal fin, and the fish head weighs 1.3kg. The cut fish head is immersed in a salt solution with a mass concentration of 1296 for deodorization treatment. The mass ratio of the fish head to the deodorization solution is 1:1, the deodorization time is 3 hours, and the salt solution and ambient temperature are ≤15°C. Take out the deodorized fish head, and wash off the mucus and blood stains on the surface with running water. After draining, put i...

Embodiment 3

[0036] Fresh bighead carp is used as raw material, and the fish weighs 2.0kg. The fish is stunned with a wooden stick and then slaughtered. Clean the scales on the surface of the fish with a stainless steel brush, carefully remove the internal organs and gills, and then use clean water to clean the remaining scales, blood stains and other debris inside and outside the fish, and remove the black film and inner ridges in the fish chamber. The blood stasis that comes out is removed cleanly. The washed fish are graded from the back of the dorsal fin, and the fish head weighs 1.1kg. The cut fish head is immersed in a salt solution with a mass concentration of 6% for deodorization treatment. The mass ratio of the fish head to the deodorization liquid is 1:1.5, the deodorization time is 3.5h, and the salt solution and ambient temperature are ≤15°C. ℃. Take out the deodorized fish head, and wash off the mucus and blood stains on the surface with running water. After draining, put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com