Flow controller

A technology of flow control device and fluid passage, applied in the direction of flow control, non-electric variable control, valve device, etc., can solve the problems of vibration and noise, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the flow control device to which the present invention is applied will be described with reference to the drawings.

[0023] [the whole frame]

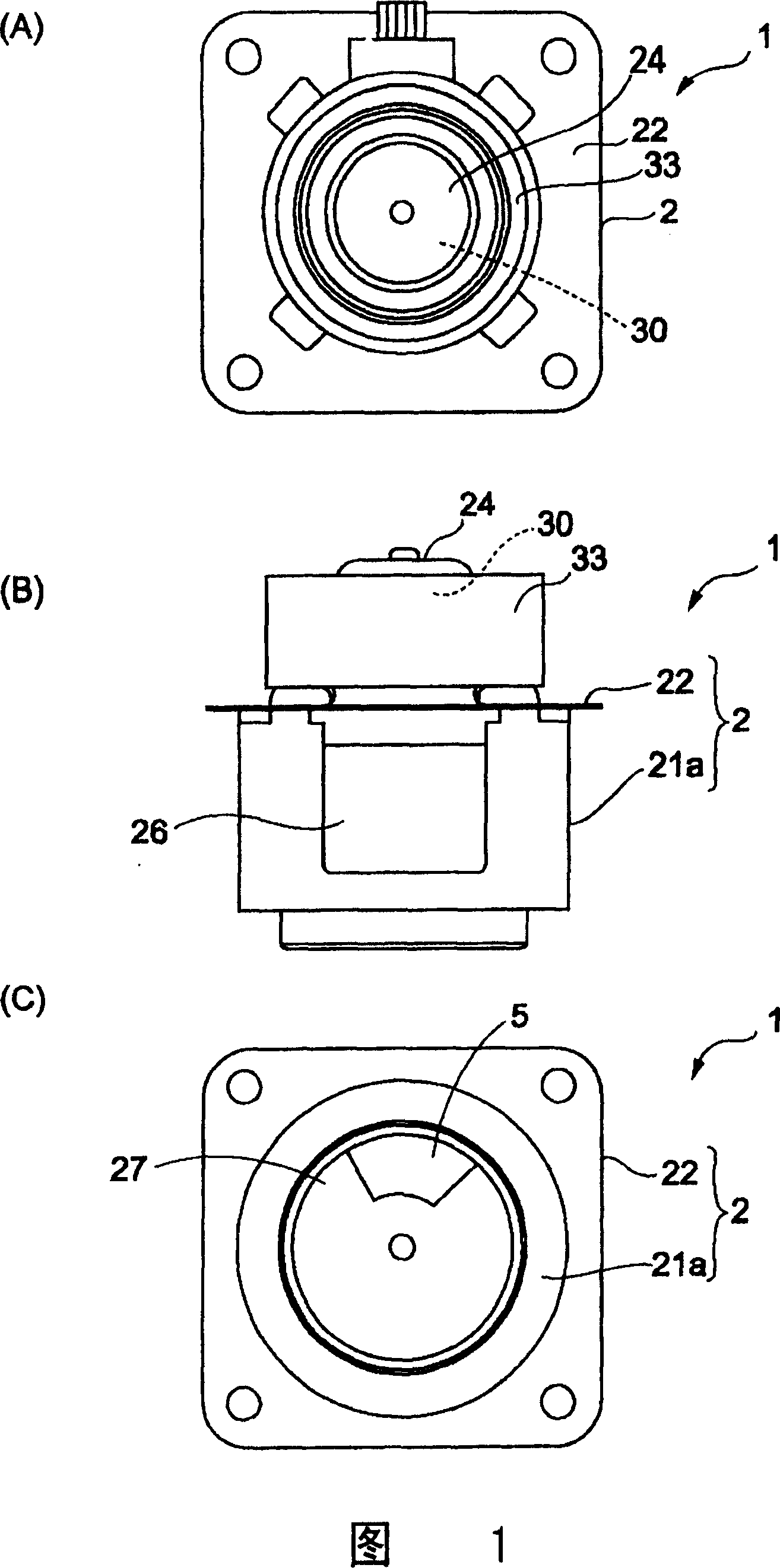

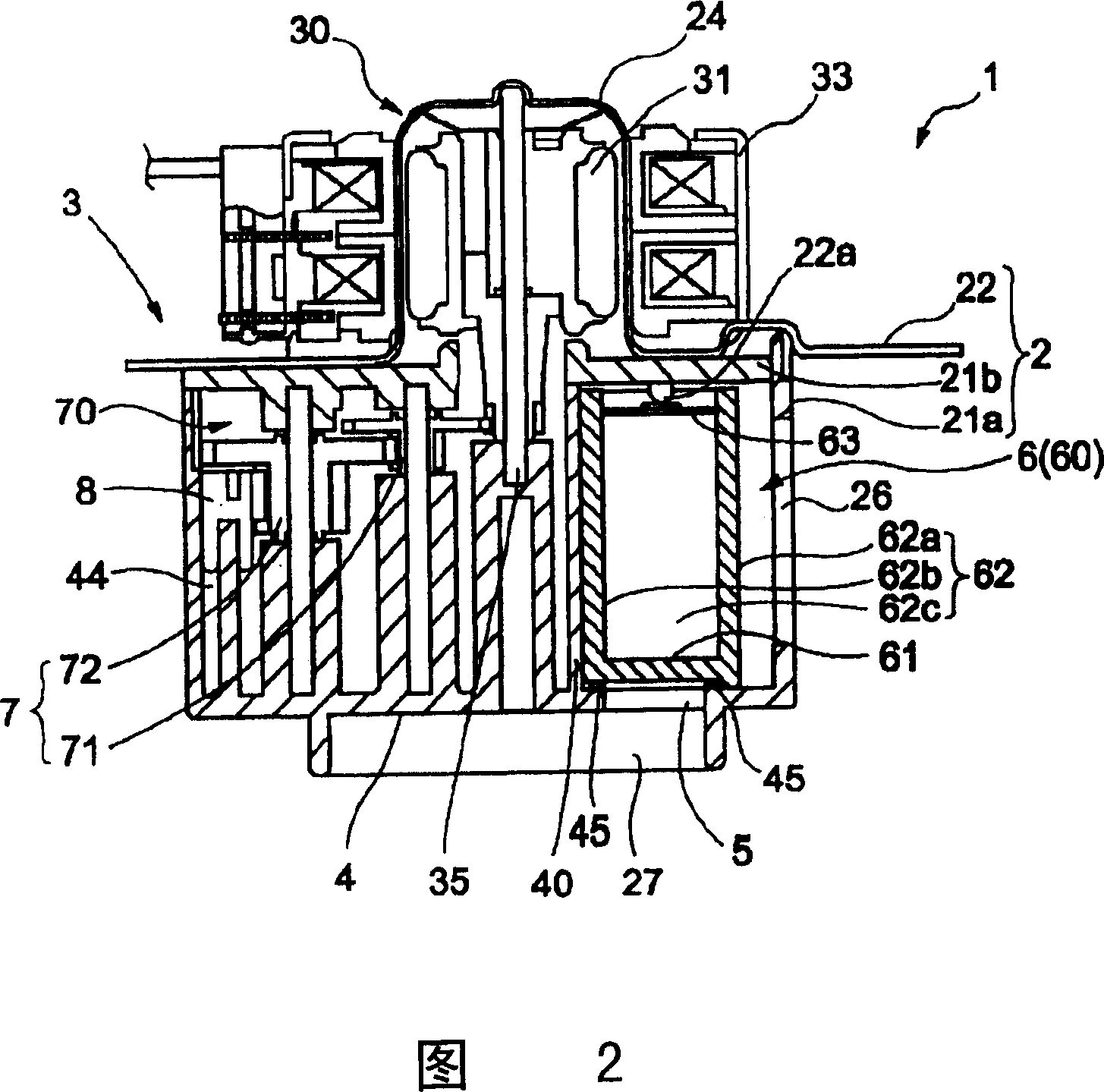

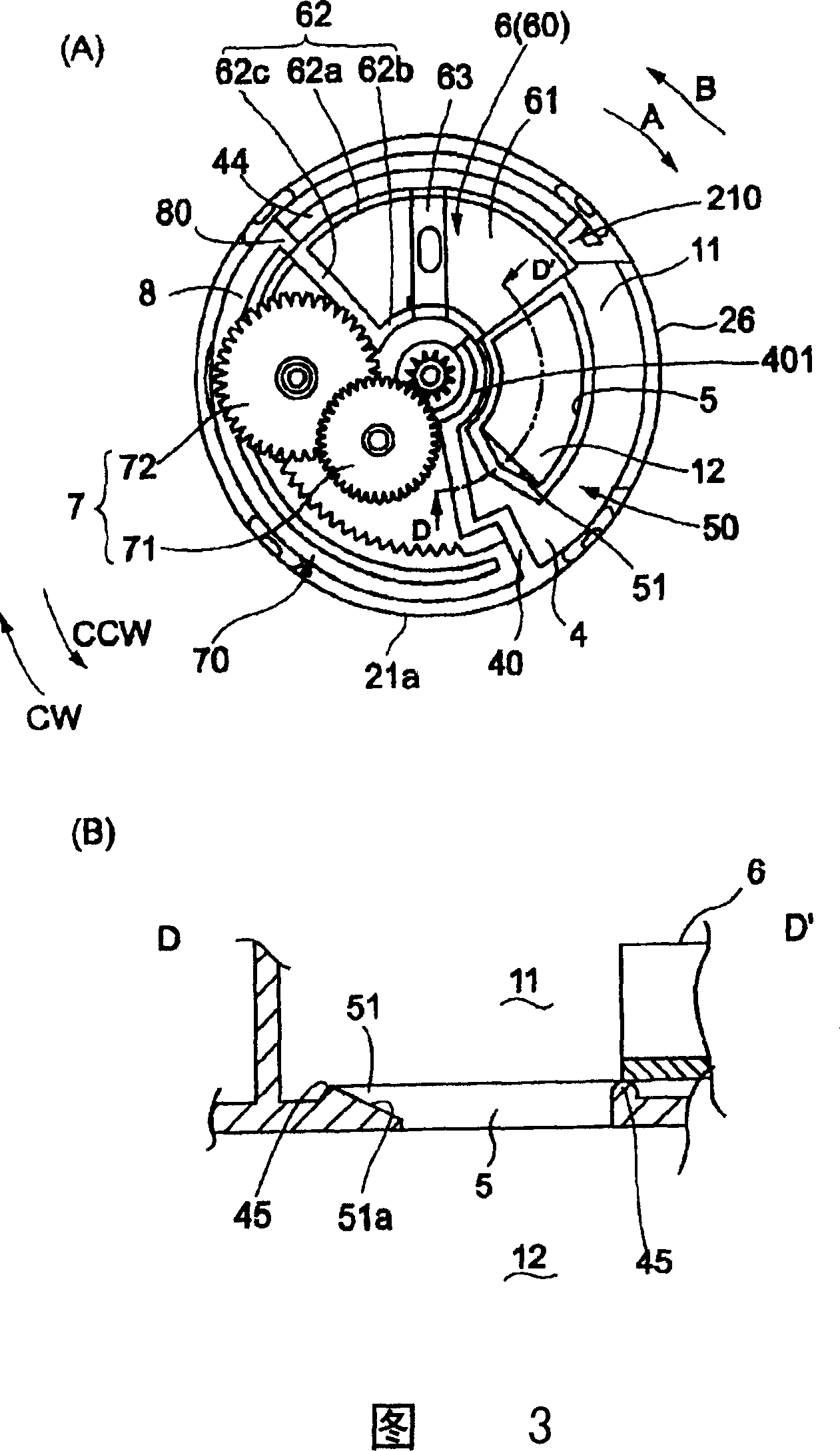

[0024] Fig. 1 (A), (B), (C) are respectively a plan view, a front view and a bottom view of a flow control device to which the present invention is applied. Fig. 2 is an expanded view of a gear set and the like arranged in a housing of a flow control device to which the present invention is applied. 3(A) and (B) are respectively a plan view and a D-D' cross-sectional view showing the opened state of the valve body in the housing of the flow control device to which the present invention is applied. 4(A) and (B) are respectively a plan view and an E-E' cross-sectional view showing the closed state of the valve body in the housing of the flow control device to which the present invention is applied.

[0025] In Figure 1 (A), (B), (C) and Figure 2, the flow control device 1 applying the present invention is used to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com