On-line cold bending steel fast punching and riveting mold and its punching and riveting method

A cold-formed steel and self-piercing riveting technology, applied in the field of metal plastic forming, can solve the problems of thermal deformation, cremation, harmful gas, high connection cost, high price, etc., and achieves smooth and beautiful riveting surface, easy maintenance and replacement, no Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

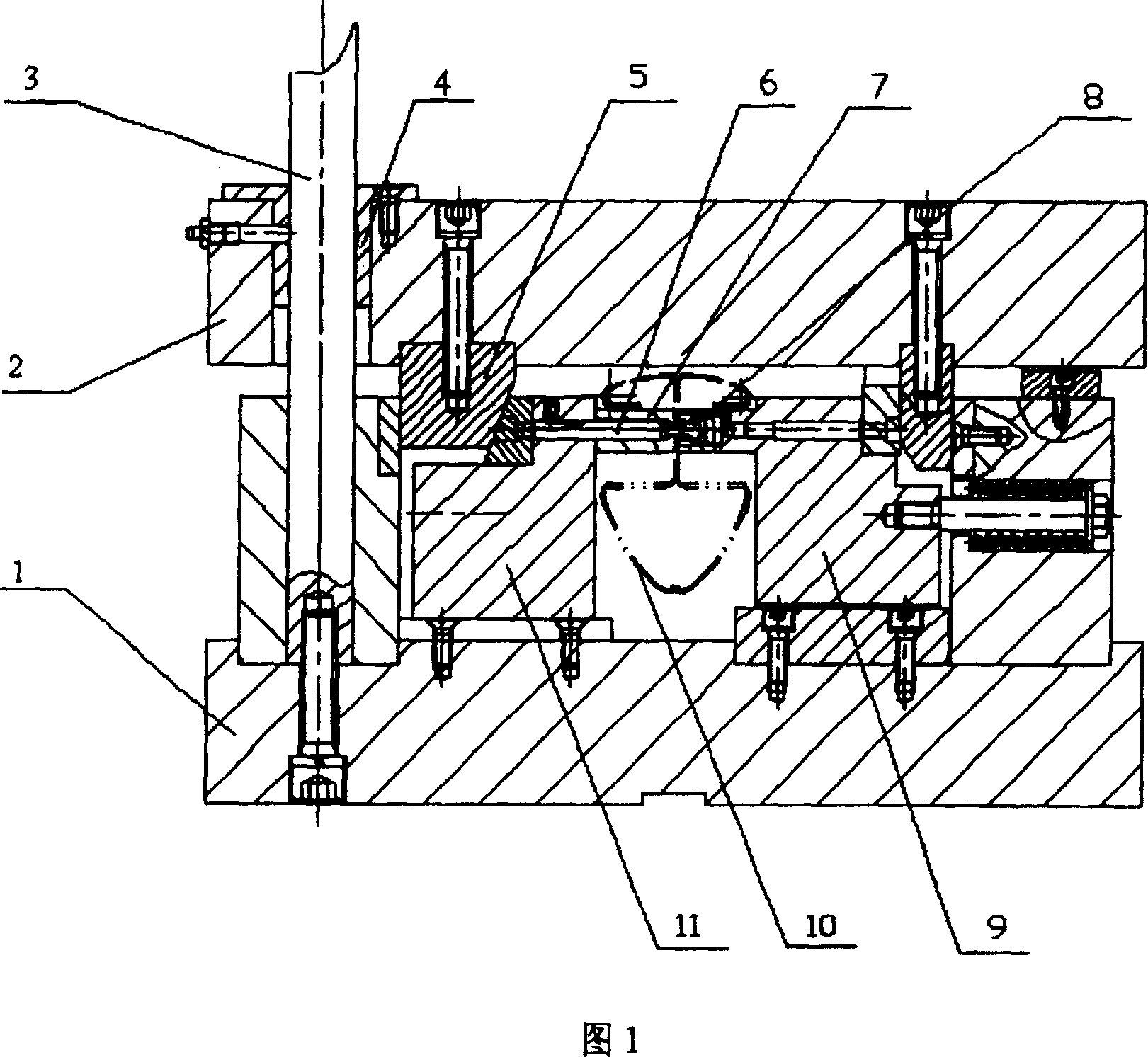

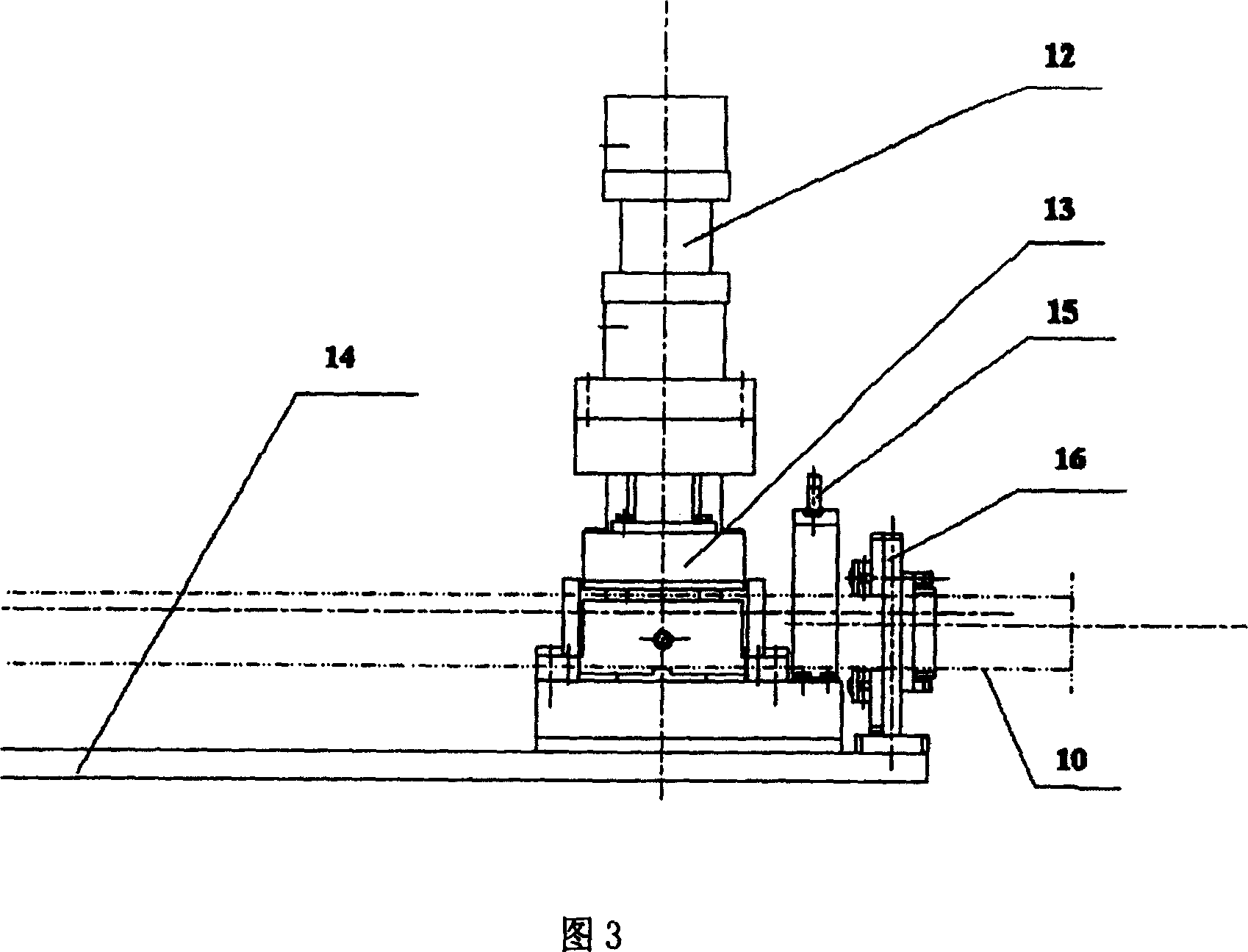

[0012] Fig. 1 and Fig. 2 are an embodiment of the present invention.

[0013] As shown in Figure 1, the self-piercing riveting mold includes two parts, the upper mold 2 and the lower mold 1, and the upper and lower molds are guided by guide pillars 3 and guide sleeves 4. The punching die 6 is fixed on the left slider 11 of the lower die, the punching die 8 is composed of three parts, the outer layer is equipped with an elastic rubber sleeve, and then installed on the ejector rod, which is installed on the right slider 9 One side of the punching riveting punch is provided with a pressing device 7; the horizontal movement of the punching riveting punch 6 and the die 8 is realized by the oblique wedge 5 and the left and right sliders 11 and 9; when the punching riveting punch 6 punches The discharged material enters the punching riveting die 8 (its structure is shown in Fig. 4, and it is made up of female die 17, push rod 18 and elastic rubber sleeve, and after the elastic rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com